AI-Driven Functional Food Formulation: Accelerating Discovery from Bioactive Compounds to Clinical Validation

This article examines the transformative role of Artificial Intelligence (AI) in revolutionizing functional food development for a scientific audience.

AI-Driven Functional Food Formulation: Accelerating Discovery from Bioactive Compounds to Clinical Validation

Abstract

This article examines the transformative role of Artificial Intelligence (AI) in revolutionizing functional food development for a scientific audience. It explores the foundational shift from traditional, slow trial-and-error methods to data-driven, AI-accelerated approaches. The scope covers the application of machine learning, deep learning, and generative AI in optimizing ingredient selection, predicting efficacy, and personalizing formulations based on biomarkers and genetics. It further addresses critical challenges, including data limitations, model interpretability, and consumer trust, while underscoring the necessity of rigorous clinical trials and comparative analysis for validating health claims. The synthesis provides a roadmap for researchers and drug development professionals to harness AI in creating effective, evidence-based functional foods for preventive health and chronic disease management.

The AI Paradigm Shift: Re-engineering Functional Food Science

The global food industry faces unprecedented pressure from climate change, volatile supply chains, and increasingly personalized consumer health demands [1]. Traditional food formulation methodologies, predominantly reliant on sequential experimental approaches and expert intuition, are fundamentally inadequate to address these complex challenges. This document details the quantitative limitations of conventional practices and establishes rigorous, data-driven protocols for implementing artificial intelligence (AI) in functional food research and development (R&D). The transition to AI-driven approaches is not merely an efficiency gain but a strategic imperative for unlocking novel functional ingredients and achieving precision health outcomes.

Quantitative Analysis: Traditional vs. AI-Driven Formulation

The following tables summarize published data on the performance disparities between traditional and AI-accelerated food formulation processes.

Table 1: Comparative Performance Metrics in Food Formulation

| Performance Metric | Traditional Formulation | AI-Driven Formulation | Data Source / Case Study |

|---|---|---|---|

| R&D Cycle Time | 12 - 24 months | 2 - 6 months (Reductions of 60-90%) | Journey Foods (60% reduction) [1]; AKA Foods (12 months to a few cycles) [1] |

| Project Onboarding Cost | Baseline | ~90% reduction | AKA Foods case study [1] |

| Ingredient Combination Evaluation | Limited by physical trials | Over 1 billion combinations screened | Journey Foods platform [1] |

| Microbial Strain Development | ~18 months | <6 months | Ginkgo Bioworks platform [1] |

| Functional Protein Yield | Baseline | Up to 25% improvement | CureCraft collaborations [1] |

Table 2: Limitations of Traditional Formulation and AI Countermeasures

| Limitation of Traditional Approach | AI-Driven Solution & Technology | Outcome |

|---|---|---|

| Trial-and-error ingredient substitution | Predictive modeling of molecular interactions & functional equivalence [1] | Faster, successful development of allergen-free, low-sugar, or vegan products |

| Inability to predict complex sensory profiles | AI models analyzing chemical structures for flavor and texture prediction [1] | Accurate replication of animal-based products with plant-based ingredients |

| Slow discovery of bioactive compounds | AI-powered bioactivity mapping (e.g., Brightseed's Forager AI) [1] | Discovery timeline shortened from years to months |

| Dependence on human sensory panels for quality control | Quantitative texture analysis via instrumentation and AI [2] | Objective, reproducible, and high-throughput quality assessment |

Experimental Protocols for AI-Enhanced Food Research

Protocol: Quantitative Texture Analysis for Legume Quality Assessment

This validated protocol supports the development of high-quality, protein-rich functional foods by providing a standardized method for quantifying texture, a critical quality attribute [2].

- 1.0 Objective: To implement a standardized destructive method for quantifying texture differences in convex legume vegetables (e.g., edamame, lima beans, peas) following processing, using compression and puncture analyses.

- 2.0 Materials and Equipment:

- Texture Analyzer (e.g., from TA.XT Plus series)

- Compression Plate: Flat, cylindrical probe with diameter greater than the sample

- Puncture Probe: Cylindrical probe with diameter smaller than the sample (e.g., 2-3 mm)

- Standard Weight for instrument calibration

- Samples: Blanched and frozen legumes, thawed under refrigeration

- 3.0 Methodology:

- 3.1 Sample Preparation: Apply three distinct processing treatments to thawed legumes:

- BFT (Control): Blanch/Freeze/Thaw only.

- BFT+M: BFT followed by microwave heating (e.g., 50g batches for 40 seconds).

- BF+C: Blanch/Freeze followed by stove-top cooking in boiling water.

- 3.2 Compression Analysis (simulates molar compression):

- Mount the compression plate on the texture analyzer.

- Place a single legume on the base plate.

- Set the test to compression mode with a defined target deformation (e.g., 50% of sample height) and pre-test speed.

- Initiate the test. The force-deformation curve is recorded.

- Key Output: Maximum Force (N) required to rupture the sample.

- 3.3 Puncture Analysis (simulates incisor bite):

- Mount the puncture probe on the texture analyzer.

- Place a single legume on the base plate.

- Set the test to puncture mode with a defined target depth and pre-test speed.

- Initiate the test. The probe penetrates the sample surface.

- Key Output: Puncture Force (N) or Bioyield Point.

- 3.1 Sample Preparation: Apply three distinct processing treatments to thawed legumes:

- 4.0 Data Analysis: Perform Analysis of Variance (ANOVA) to determine significant differences in texture attributes between legume types and processing treatments. Compression analysis has been shown to be more sensitive in detecting texture changes in edamame and lima beans [2].

Protocol: In-silico Formulation Using Predictive AI Models

This protocol outlines the use of AI platforms for the virtual screening of ingredient combinations to accelerate the initial stages of functional food development [1] [3].

- 1.0 Objective: To utilize AI-powered predictive modeling for the high-throughput identification of optimal ingredient combinations that meet target nutritional, sensory, and cost parameters.

- 2.0 Materials and Equipment:

- Access to an AI formulation platform (e.g., Journey Foods, Hoow Foods' RE-GENESYS, AKA Foods' STIR engine).

- Defined input parameters (see below).

- Computational resources (typically cloud-based, e.g., Google Cloud Vertex AI).

- 3.0 Methodology:

- 3.1 Parameter Definition: Input the following constraints and targets into the platform:

- Nutritional Targets: Specific ranges for macronutrients, micronutrients, glycemic load, or targeted bioactive compounds.

- Sensory Targets: Target flavor profiles, texture attributes (informed by Protocol 3.1), and color.

- Constraints: Excluded allergens (e.g., gluten, nuts), dietary preferences (e.g., vegan, non-GMO), cost per kilogram, and approved ingredient lists.

- Sustainability Metrics: Carbon footprint or water usage targets, if applicable.

- 3.2 Model Execution: Run the predictive simulation. The AI evaluates billions of potential combinations against the defined parameters.

- 3.3 Output Analysis: The platform returns a ranked shortlist of top-performing formulations with predicted scores for taste parity, nutrient density, cost, and sustainability.

- 3.1 Parameter Definition: Input the following constraints and targets into the platform:

- 4.0 Validation: The top-ranked virtual formulations must proceed to small-scale physical prototyping and validation through instrumental analysis (e.g., Protocol 3.1) and human sensory evaluation to confirm predictive accuracy [3]. This hybrid approach ensures innovation while mitigating the risk of AI "hallucination" or reliance on outdated data [3].

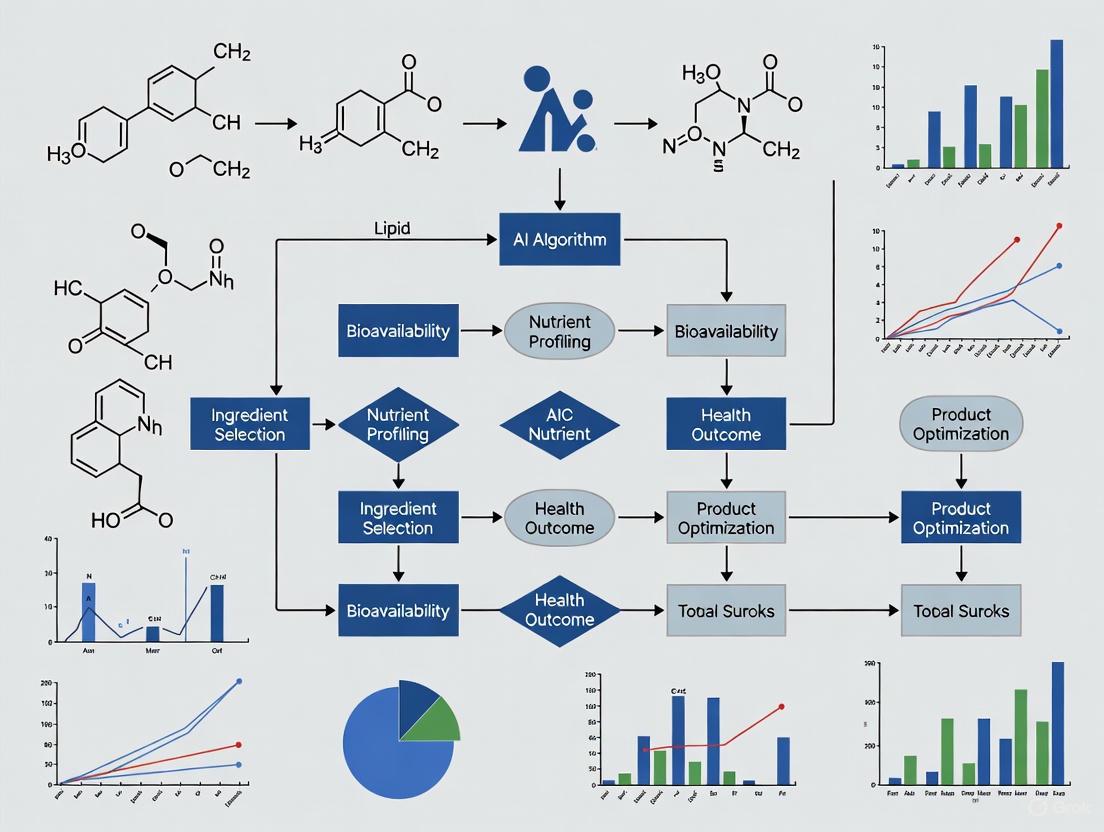

Visualization of AI-Driven Formulation Workflow

The following diagram illustrates the integrated, data-centric workflow of AI-driven functional food formulation, highlighting the continuous feedback loop that traditional methods lack.

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Research Tools for AI-Enhanced Functional Food Formulation

| Item / Solution | Function in Research | Application Note |

|---|---|---|

| Texture Analyzer | Quantifies mechanical properties (firmness, hardness, elasticity) to objectively assess product quality and validate AI texture predictions [2]. | Critical for correlating consumer sensory perception with instrumental data. Use compression for convex legumes. |

| AI Formulation Platform (e.g., RE-GENESYS, STIR) | Acts as a predictive "digital twin" for the food matrix, enabling high-throughput in-silico screening of ingredient combinations against multi-faceted constraints [1]. | Inputs must be meticulously defined by R&D scientists. Outputs require physical validation. |

| Forager AI (Brightseed) | Maps plant-based bioactives to human health biomarkers (e.g., gut health), accelerating the discovery of functional ingredients [1]. | Bridges the gap between plant genomics and nutritional science for targeted health claims. |

| Cell Engineering Platform (Ginkgo Bioworks) | Uses predictive metabolic models to program microbes for the precision fermentation of proteins, enzymes, and flavor compounds [1]. | Enables sustainable production of high-value functional ingredients at scale. |

| Standardized Legume Texture Method (ASABE S368.4) | Provides a validated, destructive method for texture analysis of convex vegetables, ensuring consistent and comparable quality data [2]. | Implementation supports efficient production of high-quality plant-based protein ingredients. |

The field of functional food formulation is undergoing a profound transformation, driven by the integration of artificial intelligence (AI). Researchers and scientists are now leveraging a diverse toolkit of AI technologies to accelerate the discovery and development of foods with targeted health benefits. This toolkit can be broadly categorized into non-generative AI, which analyzes, improves, or infers data, and generative AI, which creates novel data, formulations, and ideas [4]. Non-generative applications include optimization, discovery, and prediction, while generative AI focuses on the creation of entirely new product concepts and ingredient combinations [4]. This article details the specific applications, protocols, and reagent solutions that define the modern, AI-driven approach to functional food research, providing a framework for scientists to integrate these tools into their development pipelines.

The Non-Generative AI Toolkit: Optimization, Discovery, and Prediction

Non-generative AI provides the foundational capabilities for enhancing existing research and development processes. Its power lies in processing massive, complex datasets to identify patterns, predict outcomes, and optimize parameters far beyond human capacity.

Key Applications and Methodologies

Optimization of Ingredient Combinations and Process Parameters: AI algorithms, particularly machine learning (ML) models, can fine-tune variables to achieve the best possible outcome under specific constraints [4]. This is crucial for achieving desired nutritional profiles, sensory attributes, and cost targets simultaneously.

- Protocol Example – Predictive Formulation Optimization:

- Objective: Optimize a plant-based protein formulation for maximum protein content, specific texture profile, and minimal cost.

- Data Curation: Compile a historical dataset containing ingredient ratios (e.g., pea, soy, wheat gluten), processing conditions (e.g., extrusion temperature, pressure), and corresponding outcomes (nutritional analysis, texture measurements, production cost).

- Model Selection & Training: Employ a multi-objective optimization algorithm, such as a genetic algorithm or Bayesian optimization, trained on the curated dataset.

- In-silico Experimentation: The AI model runs thousands of virtual experiments, exploring the parameter space to identify Pareto-optimal formulations—those where one objective cannot be improved without sacrificing another [1].

- Validation: The top candidate formulations identified by the AI are physically produced in a lab and subjected to standard analytical and sensory testing to validate the model's predictions [5].

- Protocol Example – Predictive Formulation Optimization:

Discovery of Bioactive Compounds: AI can rapidly scan vast biological and chemical datasets to identify novel functional ingredients.

- Protocol Example – AI-Driven Bioactive Discovery:

- Objective: Identify novel plant-derived compounds with prebiotic effects for gut health.

- Data Integration: The AI platform, such as Brightseed's Forager, is fed multi-omics data (genomics, proteomics, metabolomics) from thousands of plant species, alongside existing scientific literature on gut microbiology and health biomarkers [1] [5].

- Predictive Mapping: Deep learning models map the molecular structures of plant compounds to potential biological targets and mechanisms of action in the human gut [5].

- Prioritization & Validation: The platform generates a shortlist of high-probability candidate compounds and their plant sources. These candidates then proceed to in-vitro and eventually clinical validation, dramatically compressing a discovery process that traditionally took years into months [1] [5].

- Protocol Example – AI-Driven Bioactive Discovery:

Prediction of Consumer Acceptance and Shelf-Life: Predictive modeling forecasts outcomes or behaviors, such as how a target demographic will perceive a product's taste or how long a product will remain stable [4].

- Protocol Example – Developing a Digital Consumer Twin:

- Objective: Predict the liking score for a new functional beverage concept among health-conscious millennials before physical prototyping.

- Data Collection: Aggregate data from past consumer tests, sensory panel results, market trends, and demographic information.

- Model Training: Train a predictive ML model (e.g., a regression or classification model) to correlate product attributes (sweetness, acidity, flavor notes) with consumer preference scores for the target demographic.

- Simulation: The trained "digital twin" of the consumer segment is used to screen millions of virtual formulation variations, predicting acceptance and identifying the most promising profiles for physical testing [5].

- Protocol Example – Developing a Digital Consumer Twin:

Quantitative Data on Non-Generative AI Impact

The following table summarizes performance data and evidence for established non-generative AI applications in food research.

Table 1: Performance Data for Non-Generative AI Applications in Food Formulation

| AI Application | Reported Performance/Uptake | Key Companies/Platforms | Primary Data Sources |

|---|---|---|---|

| Optimization | Compressed concept-to-launch timelines by 4-5 fold; used in 70+ projects [5]. | Mondelez (in collaboration with Thoughtworks) [5]. | Historical formulation data, sensory data, cost data, nutritional guidelines. |

| Discovery | Reduced bioactive discovery timeline from years to months [1] [5]. | Brightseed (Forager AI) [1] [5]. | Multi-omics data, scientific literature, chemical databases. |

| Prediction | Cut time-to-concept by 30-50% via virtual consumer testing [5]. | Foodpairing (Digital Twins) [5]. | Sensory data, consumer test results, market data, flavor chemistry. |

Workflow Visualization: Non-Generative AI for Formulation

The following diagram illustrates a generalized workflow for employing non-generative AI in functional food formulation.

The Generative AI Toolkit: Creating Novelty

Generative AI represents a paradigm shift, moving beyond analysis to the creation of novel formulations, product concepts, and even processing methods. It leverages architectures like large language models (LLMs) and generative adversarial networks (GANs) to produce original outputs based on learned patterns.

Key Applications and Methodologies

Generative Formulation Design: AI can propose entirely new ingredient combinations to meet specific, multi-faceted goals.

- Protocol Example – Generative Plant-Based Product Development:

- Objective: Create a novel plant-based formulation that mimics the taste, texture, and nutritional profile of a specific animal product (e.g., beef burger).

- Problem Framing: The target product's sensory and nutritional specifications are defined as the input constraints for the AI.

- AI Generation: A generative AI platform, such as NotCo's Giuseppe, explores a near-infinite combinatorial space of plant ingredients. It uses deep learning models that understand the molecular and functional properties of plants to propose combinations that match the target [1] [5].

- Output and Iteration: The AI generates a shortlist of feasible formulations. These are then prototyped, and the results are fed back into the AI to iteratively refine its models and improve future outputs [5].

- Protocol Example – Generative Plant-Based Product Development:

Accelerated Front-End Innovation: Generative AI can mine consumer insights and rapidly generate and iterate product concepts.

- Protocol Example – AI-Powered Ideation:

- Objective: Generate novel functional beverage concepts targeting cognitive health for an aging population.

- Knowledge Grounding: Use a Retrieval-Augmented Generation (RAG) system. This architecture grounds the generative AI in trusted, domain-specific sources such as scientific journals, internal research documents, and regulatory guidelines [6].

- Prompting and Generation: Researchers query the system using natural language (e.g., "Generate 5 beverage concepts for cognitive support using ingredients compliant with FDA GRAS status"). The AI synthesizes the knowledge base to produce detailed concepts, including potential ingredient lists and health narratives [5] [6].

- Feasibility Screening: The generated concepts can be automatically screened against cost, sustainability, or manufacturability databases to prioritize the most viable ideas for further development [5].

- Protocol Example – AI-Powered Ideation:

Quantitative Data on Generative AI Impact

The table below summarizes evidence for the emerging impact of generative AI in food formulation research.

Table 2: Evidence for Generative AI Applications in Food Formulation

| AI Application | Reported Performance/Evidence | Key Companies/Platforms | Key Enabling Technology |

|---|---|---|---|

| Generative Formulation | Ability to search through 260 quintillion combinations to land on a 5-protein blend for a target product [5]. | NotCo (Giuseppe AI) [1] [5]. | Deep Learning, Knowledge Graphs. |

| Concept Generation & Ideation | Meaningful acceleration of ideation and concept screening; faster, more efficient generation and testing of ideas [5]. | Nestlé (NesGPT, proprietary tools) [5]. | Large Language Models (LLMs), Retrieval-Augmented Generation (RAG). |

| Sustainable Packaging | AI can propose novel, eco-friendly packaging materials, reducing R&D time from years to days [7]. | Nestlé & IBM Research [7]. | Generative AI for Material Science. |

Workflow Visualization: Generative AI for Novel Food Creation

The following diagram illustrates the iterative cycle of generative creation and refinement in functional food formulation.

The Scientist's Toolkit: Essential Research Reagent Solutions

The following table details key AI platforms and data solutions that function as essential "research reagents" in the modern functional food laboratory.

Table 3: Key AI Platform "Reagents" for Functional Food Research

| Platform / Solution | Function in Research | Typical Inputs | Typical Outputs |

|---|---|---|---|

| Brightseed Forager [1] [5] | AI for bioactive discovery; maps plant compounds to human biology. | Multi-omics data, scientific literature. | Shortlist of predicted bioactive compounds & their sources for validation. |

| NotCo Giuseppe [1] [5] | Generative AI for plant-based formulation; mimics animal products. | Target product specifications (taste, texture, nutrition). | Novel, feasible plant-based ingredient combinations & recipes. |

| Journey Foods Platform [1] | Predictive ingredient optimization for CPGs. | Nutrient density, allergenicity, cost, sustainability goals. | Reformulated product recipes optimized for multiple constraints. |

| Foodpairing Digital Twins [5] | Predictive modeling of consumer preference. | Sensory data, market trends, demographic info. | Virtual taste-test results and predicted liking scores for formulations. |

| RAG System [6] | Knowledge management and grounded ideation. | Internal R&D documents, scientific journals, regulatory info. | Scientifically-grounded product concepts and answers to research queries. |

The convergence of artificial intelligence (AI) and nutritional science is revolutionizing the development of functional foods. By 2050, feeding a global population of nearly 10 billion will require transformative changes to create nutritious, sustainable food systems, a challenge where traditional methods are too slow to drive innovation at scale [4]. AI technologies are now being leveraged to accelerate the discovery and optimization of key bioactive compounds, including probiotics, prebiotics, and plant-based bioactives. This paradigm shift enables researchers to move beyond traditional trial-and-error approaches, using machine learning (ML) and deep learning (DL) to analyze complex biological datasets and predict bioactivity with unprecedented speed and precision [8] [9]. The integration of AI across the functional food development pipeline—from strain selection and metabolite prediction to personalized formulation—represents a critical advancement in creating targeted health solutions that meet individual biological needs while promoting planetary health [10].

AI-Driven Probiotic Discovery and Optimization

Strain Screening and Functional Annotation

The application of AI has dramatically transformed the initial stages of probiotic research, particularly in strain screening and functional annotation. Where traditional methods relied on labor-intensive, low-throughput in vitro experiments, AI algorithms can now rapidly analyze genomic data to identify promising probiotic candidates with specific functional traits [9].

Table 1: AI Applications in Probiotic Strain Discovery

| AI Application | Traditional Approach | AI-Enhanced Approach | Reported Efficacy |

|---|---|---|---|

| Strain Screening | Time-consuming in vitro tests for acid/bile tolerance [11] | Genomic feature analysis using ML models [9] | >97% accuracy in bacterial identification [9] |

| Functional Annotation | Empirical selection and manual characterization [8] | Prediction of probiotic traits (e.g., AMP production, SCFA synthesis) via DL [8] | Identification of tRNA sequences as key genomic features [9] |

| Pathogen Discrimination | Phenotypic differentiation assays | ML analysis of genomic features distinguishing probiotics from pathogens [9] | tRNA identified as key discriminatory biomarker [9] |

Experimental Protocol: AI-Guided Probiotic Screening

Objective: To rapidly identify novel probiotic LAB strains with specific health-promoting properties using AI-driven genomic analysis.

Materials and Reagents:

- Genomic DNA Extraction Kit: For high-quality DNA isolation from bacterial samples

- Whole Genome Sequencing Platform: Illumina or Nanopore for genomic data generation

- AI/ML Software Environment: Python with scikit-learn, TensorFlow/PyTorch for DL

- Reference Databases: KEGG, GO, UniProt for functional annotation

- In vitro Validation Assays: MRS broth, gastric juice simulation solution, bile salts, cell culture models

Methodology:

- Genomic Data Acquisition: Perform whole-genome sequencing on candidate LAB isolates from diverse sources (fermented foods, human microbiota) [8].

- Feature Engineering: Extract genomic features including tRNA sequences, GC content, presence of virulence genes, and stress resistance markers using bioinformatics tools [9].

- Model Training: Implement supervised ML algorithms (Random Forest, SVM) trained on known probiotic and non-probiotic strains with labeled functional attributes [8] [12].

- Predictive Screening: Apply trained models to screen unknown isolates for probiotic potential, focusing on:

- Acid and bile tolerance: Predict survival under gastrointestinal conditions

- Antimicrobial peptide production: Identify genes encoding bacteriocins

- Host-microbe interaction potential: Predict adhesion and immunomodulatory properties [8]

- In vitro Validation: Confirm AI predictions through standard assays:

- Acid (pH 2.0, 3h) and bile salt (0.3%, 4h) tolerance tests

- Antimicrobial activity against pathogens via agar well diffusion

- Caco-2 cell adhesion assays [11]

AI-Guided Probiotic Screening Workflow

AI in Prebiotic and Plant-Based Bioactive Research

Metabolite Prediction and Bioactivity Assessment

AI technologies are revolutionizing the discovery of prebiotics and plant-based bioactives by enabling sophisticated metabolite prediction and bioactivity assessment. Through integration of multi-omics data, AI models can identify novel prebiotic compounds and predict their effects on human health, significantly accelerating the discovery pipeline [13].

Table 2: AI Applications in Prebiotic and Bioactive Discovery

| Bioactive Category | AI Application | Mechanism of Action | Validated Outcomes |

|---|---|---|---|

| Prebiotics (FOS, GOS, Inulin) | Prediction of SCFA production via metabolic modeling [13] | Selective stimulation of beneficial bacteria (Lactobacillus, Bifidobacterium) [13] | Increased acetate, propionate, and butyrate in in vitro fermentation [13] |

| Dietary Fibers | ML analysis of gut microbiota modulation [13] | Alteration of microbial SCFA profiles [13] | Anti-obesity and antidiabetic effects in murine models [13] |

| Plant-Based Bioactives | Molecular docking and bioactivity prediction [10] | Modulation of inflammation, oxidative stress, and metabolic pathways [10] | Identification of anti-cancer and neuroprotective properties [10] |

Experimental Protocol: AI-Driven Bioactive Compound Discovery

Objective: To identify and validate novel prebiotic compounds and plant-based bioactives using AI-powered analysis of multi-omics data.

Materials and Reagents:

- Plant Material/Sources: Diverse botanical extracts, agricultural by-products

- Analytical Equipment: LC-MS/MS for metabolomic profiling, HPLC for compound purification

- AI Platforms: Molecular docking software (AutoDock, SwissDock), deep learning frameworks

- In vitro Fermentation System: Anaerobic chamber, gut microbiome models

- Cell Culture Models: Caco-2, HT-29 for intestinal barrier function assessment

Methodology:

- Data Collection and Integration:

- Perform untargeted metabolomics on plant sources using LC-MS/MS

- Curate existing databases of bioactive compounds and their known health effects

- Integrate genomic data of gut microbiota strains for target identification [13]

Predictive Modeling:

- Train neural networks on structure-activity relationships to predict prebiotic potential

- Implement molecular docking simulations to identify compounds with high affinity for microbial enzymes or host receptors [10]

- Use clustering algorithms to group compounds with similar structural features and predicted bioactivities

In vitro Validation:

- Conduct anaerobic fermentation with human fecal inoculum to assess SCFA production

- Measure growth stimulation of specific beneficial bacterial strains (Bifidobacterium, Lactobacillus)

- Evaluate immunomodulatory effects on co-culture systems of intestinal epithelial and immune cells [13]

Dose-Response Studies:

- Establish effective concentration ranges for predicted bioactivities

- Assess potential cytotoxicity in human cell lines

- Evaluate synergistic effects between identified compounds [10]

Industrial Application and Personalized Nutrition

Fermentation Optimization and Formulation

AI-driven approaches are transforming industrial-scale production of probiotic and bioactive-containing products through optimized fermentation processes and personalized formulations. These technologies enable precise control over critical parameters that determine final product viability, functionality, and efficacy [8] [9].

Table 3: AI in Industrial-Scale Probiotic and Bioactive Production

| Industrial Process | AI Technology | Application | Impact |

|---|---|---|---|

| Fermentation Optimization | Hybrid modeling (ML + mechanistic) [8] | Predicts optimal temperature, pH, nutrient feed rates | Enhances biomass yield and bioactive metabolite production [8] |

| Formulation Stability | Predictive stability models [11] | Analyzes excipient interactions, predicts shelf-life | Improves probiotic viability during storage [11] |

| Personalized Nutrition | Reinforcement learning [14] | Generates individual-specific formulations based on microbiome data | Creates targeted solutions for specific health conditions [9] |

The Scientist's Toolkit: Essential Research Reagents and Platforms

Table 4: Key Research Reagent Solutions for AI-Driven Bioactive Compound Research

| Reagent/Platform | Function | Application Context |

|---|---|---|

| Multi-omics Data Generation Platforms | Generates genomic, metabolomic, and proteomic data for AI analysis | Strain characterization, bioactive compound discovery [8] [10] |

| AI/ML Software Environments | Provides algorithms for predictive modeling and data analysis | Strain screening, metabolite prediction, fermentation optimization [8] [14] |

| In vitro Gut Microbiome Models | Simulates human gut environment for functional validation | Prebiotic efficacy testing, host-microbe interaction studies [13] [12] |

| Encapsulation Technologies | Enhances stability and targeted delivery of bioactives | Improved probiotic viability, controlled release of compounds [13] |

| Biosensors and Monitoring Systems | Provides real-time data on process parameters and cell viability | Fermentation monitoring, storage stability assessment [11] |

AI-Driven Product Development Pipeline

The integration of AI into functional food research represents a paradigm shift in how we discover, develop, and deliver bioactive compounds. The protocols and applications outlined in this document demonstrate the transformative potential of AI technologies to accelerate the identification of novel probiotics, prebiotics, and plant-based bioactives while enabling personalized nutrition solutions tailored to individual microbiome profiles [8] [9] [14]. As these technologies continue to evolve, they promise to bridge the gap between human health and planetary sustainability by facilitating the development of targeted, evidence-based functional foods [10]. Future advancements will likely focus on improving model interpretability, integrating more diverse data sources, and establishing standardized validation frameworks to ensure the efficacy and safety of AI-discovered bioactive compounds. The convergence of AI and nutritional science marks the beginning of a new era in which data-driven approaches will fundamentally reshape our relationship with food and health.

This document provides detailed protocols for implementing artificial intelligence (AI) to advance functional food research from population-level guidance to dynamic, personalized nutrition. By integrating biomedical, behavioral, and food environment data, these AI-driven methodologies enable the formulation of functional foods tailored to individual physiological needs and the delivery of personalized dietary recommendations. These approaches address the documented limitations of traditional one-size-fits-all nutritional guidelines and slow, iterative food development processes, which are often inefficient and fail to account for individual variability in response to diet [4] [15]. The following sections present structured data, experimental protocols, and essential toolkits to facilitate the adoption of these techniques in research and development.

Quantitative Data on AI-Driven Personalization

Table 1: Performance of AI Models in Personalized Nutrition and Food Recommendation

| Model/Algorithm | Application Context | Key Performance Metric | Result | Citation |

|---|---|---|---|---|

| Deep Q-Network (DQN) | Food Recommendation (Population: "Foodies") | Improvement in Accumulated Reward vs. Random Recommender | +71.60% | [16] |

| Deep Q-Network (DQN) | Food Recommendation (Population: "Veggies") | Improvement in Accumulated Reward vs. Random Recommender | +65.02% | [16] |

| Deep Q-Network (DQN) | Food Recommendation (Population: "Spanish") | Improvement in Accumulated Reward vs. Random Recommender | +63.46% | [16] |

| Deep Q-Network (DQN) | Food Recommendation (Population: "Seniors") | Improvement in Accumulated Reward vs. Random Recommender | +8.89% | [16] |

| Reinforcement Learning | Glycemic Control | Reduction in Glycemic Excursions | Up to 40% | [17] |

| Diet Engine (YOLOv8) | Real-time Food Recognition | Classification Accuracy | 86% | [17] |

| CNN-based Models | Food Image Classification | Standard Dataset Accuracy | >85% | [17] |

| Transformer-based Models | Fine-grained Food Identification | Accuracy (e.g., on CNFOOD-241) | >90% | [17] |

| Symbolic Knowledge Extraction | Explainable Dietary Recommendations | Precision and Fidelity | 74% Precision, 80% Fidelity | [17] |

Table 2: Global Functional Food and Beverages Market Data (2022-2027)

| Market Segment | Projected Compound Annual Growth Rate (CAGR) | Market Size in 2022 | Projected Market Size by 2027 | Citation |

|---|---|---|---|---|

| Overall Functional Foods & Beverages | 8.4% | $216.4 billion | $324.4 billion | [18] |

| Functional Food Subcategories | ||||

| Bakery and Confectionery | 8.1% (for total segment) | $46.5 billion | $74.2 billion | [18] |

| Cereal and Flour | 8.1% (for total segment) | $46.5 billion | $74.2 billion | [18] |

| Dairy (non-drinkable) | 8.1% (for total segment) | $46.5 billion | $74.2 billion | [18] |

| Functional Beverage Subcategories | ||||

| Energy Drinks | 8.1% (for total segment) | $46.5 billion | $74.2 billion | [18] |

| Prebiotic and Probiotic Drinks | 8.1% (for total segment) | $46.5 billion | $74.2 billion | [18] |

Experimental Protocols

Protocol 1: Reinforcement Learning for Population-Specific Food Recommendation

This protocol outlines the procedure for developing and validating a reinforcement learning (RL) model to generate personalized meal recommendations for distinct demographic populations, thereby enhancing user satisfaction and supporting demand-driven supply chain management [16].

I. Materials and Equipment

- Computational hardware (GPU recommended for Deep RL models).

- Software environment for machine learning (e.g., Python with libraries such as TensorFlow, PyTorch, Stable-Baselines3).

- A database of dishes tagged with categories (e.g., rice, pasta, legumes, vegetables, white meat, red meat, fish, fried, egg, dairy, fruit) and attributes (e.g., traditional, innovative, vegetarian, vegan) [16].

II. Experimental Procedure

Step 1: Population Simulation using Fuzzy Logic

- Input: Collect or define demographic variables for user profiles: age, gender, geographical area, and city size [16].

- Fuzzification: Convert input values into fuzzy sets using membership functions. For example, age can be fuzzified into sets like "young," "middle-aged," and "senior" with overlapping boundaries [16].

- Rule Application & Defuzzification: Apply a set of predefined fuzzy rules (e.g., "IF age is senior AND location is coastal THEN preference for fish is high") to map demographic inputs to culinary preferences. Convert the fuzzy output sets into crisp values representing a user's preference score for different dish tags or types [16].

- Output: Generate multiple user profiles with associated preference vectors, aggregated into specific population groups (e.g., "Seniors," "Veggies," "Foodies") for testing.

Step 2: Algorithm Implementation and Training

- Selection: Choose one or more RL algorithms for comparison. Recommended algorithms include:

- State–Action–Reward–State–Action (SARSA): An on-policy temporal difference learning algorithm [16].

- Deep Q-Network (DQN): A value-based deep RL algorithm that uses a neural network to approximate the Q-function [16].

- Multi-Armed Bandit (MAB): A simpler approach that balances exploration and exploitation of menu options [16].

- Simulation Environment: Create a simulation where the agent (recommender system) interacts with the environment (simulated user from a specific population). The agent recommends a dish (action), and the environment returns a reward based on the user's predefined preferences.

- Training: Train each RL agent over multiple episodes. The agent's goal is to maximize the cumulative reward by learning a policy that maps user states (or contexts) to optimal dish recommendations.

Step 3: Model Evaluation and Validation

- Metric Calculation: For each population group, evaluate the performance of the trained models using the accumulated reward over a set number of interactions. Compare this against a baseline, such as a random recommender [16].

- Statistical Analysis: Perform statistical tests (e.g., t-tests) to determine if performance differences between algorithms and across populations are significant. Report p-values and effect sizes (e.g., Cliff's delta) [16].

- Validation: The model is considered validated for a target population when it shows a statistically significant (p < 0.05) improvement over the baseline recommender.

Protocol 2: AI-Driven Formulation of Personalized Functional Foods

This protocol describes a methodology for using AI to discover and optimize formulations for plant-based alternative protein products, accelerating the traditional R&D cycle [4].

I. Materials and Equipment

- Database of ingredients (e.g., protein sources: soy, pea, wheat gluten; fats: coconut oil, canola oil; binders: methylcellulose, starch; functional additives: carrageenan, lecithin) and their functional properties [4].

- Dataset of chemical, rheological, textural, and sensory properties correlated to formulations. (Note: The scarcity of such data is a current limitation [4]).

- AI platform capable of optimization and generative algorithms (e.g., KNIME Analytics Platform, custom Python scripts) [4] [19].

II. Experimental Procedure

Step 1: Problem Definition and Constraint Setting

- Define Target Product: Identify the specific animal product to mimic (e.g., beef burger, chicken sausage). Establish key target features: nutritional profile (e.g., high protein, low saturated fat), texture, flavor, and appearance [4].

- Set Constraints: Impose constraints on the formulation, which may include:

- Nutritional boundaries (e.g., minimum protein content, maximum sodium).

- Ingredient inclusion/exclusion (e.g., allergens, cost limits).

- Sustainability metrics (e.g., carbon footprint, water usage) [4].

Step 2: AI-Driven Formulation Generation and Optimization

- Model Selection: Employ a generative AI or optimization algorithm. Non-generative AI can be used for optimization (fine-tuning variables) and discovery (identifying patterns), while generative AI can create entirely new formulation combinations based on the constraints [4].

- Input Parameters: Encode the constraints and target properties from Step 1 as inputs to the AI model.

- Execution: Run the AI model to generate a set of candidate formulations. Each formulation is a list of ingredients with their respective ratios or weights [4].

- Prediction: Use predictive AI models (if validated data exists) to forecast the nutritional profile, estimated texture, and flavor of the candidate formulations [4].

Step 3: Validation and Iteration

- Prototyping: Produce physical prototypes based on the top AI-generated formulations.

- Laboratory Analysis: Conduct analytical tests to measure the nutritional composition, rheology (e.g., tensile, compression, shear strength), and sensory attributes of the prototypes [4].

- Consumer Testing: Perform blinded consumer surveys to assess acceptability, texture, and flavor preferences [4].

- Feedback Loop: Feed the laboratory and consumer data back into the AI model to refine its predictions and generate improved formulations in subsequent iterations. This闭环反馈 significantly reduces the number of trial-and-error cycles required compared to traditional methods [4].

Visualization of Workflows

AI-Personalized Nutrition System

Functional Food AI Formulation

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for AI-Driven Personalized Nutrition Research

| Item | Function/Application | Example Specifications |

|---|---|---|

| Continuous Glucose Monitor (CGM) | Captures real-time, high-frequency interstitial glucose data to understand individual glycemic responses to food and provide dynamic feedback for AI models. | [20] [17] |

| Food Image Recognition Database | Used to train and validate computer vision models for automated dietary assessment via smartphone cameras. Requires large, labeled datasets. | e.g., CNFOOD-241; Accuracies >85-90% [17] |

| Fuzzy Logic Simulation Tool | Generates synthetic user populations with realistic culinary preferences based on demographic data for robust testing of recommender systems. | e.g., Python scikit-fuzzy library; Inputs: age, gender, geography [16] |

| Ingredient Property Database | A structured database containing chemical, functional, and sensory properties of ingredients, which is foundational for AI-driven formulation generation. | Includes protein sources, fats, binders, additives [4] |

| Reinforcement Learning Library | Provides pre-built algorithms (e.g., DQN, SARSA) for developing and training adaptive, personalized recommendation systems. | e.g., TensorFlow Agents, Stable-Baselines3 (Python) [16] |

| KNIME Analytics Platform | An open-source platform for data integration, processing, and analysis, enabling the creation of machine learning workflows without extensive coding, particularly useful for cheminformatics. | [19] |

| Tree Ensemble Regression Model | A powerful machine learning model for predicting continuous outcomes (e.g., shelf-life, glycemic response) from complex, multi-parameter input data. | e.g., Random Forest, Gradient Boosted Trees; High R² values [19] |

AI in Action: Machine Learning for Ingredient Discovery and Formulation Optimization

The formulation of effective functional foods represents a complex challenge, requiring the identification of bioactive ingredients and an understanding of their synergistic interactions. Food synergy—the concept that the health effects of a whole food or dietary pattern are greater than the sum of the effects of its individual nutrients—provides the necessary theoretical underpinning for this approach [21]. However, the vast, disparate, and unstructured nature of nutritional science literature and clinical data makes manual analysis impractical. Natural Language Processing (NLP) and Artificial Intelligence (AI) have emerged as transformative technologies for automating the extraction and analysis of this information, enabling data-driven ingredient selection and synergy discovery [22]. This document outlines protocols for applying NLP to mine scientific and clinical data, thereby accelerating AI-driven functional food formulation.

NLP and AI in Food Science: Core Concepts and Applications

The application of NLP in food science involves using computational techniques to parse, understand, and derive meaning from human language data found in scientific papers, clinical trial reports, patents, and food labels.

Key Application Areas

- Automated Food Categorization and Nutrient Profiling: NLP models can automatically classify food products into categories and predict their nutritional quality based on text from food labels. One study achieved an accuracy of 0.98 in predicting major food categories and an R² of 0.87 in predicting nutrition quality scores, significantly outperforming traditional methods [23].

- Linking Recipes to Nutrition and Sustainability: AI and NLP tools are critical for structuring recipe data and linking ingredients to nutritional databases and sustainability metrics, such as carbon footprint. This allows for the computational analysis of a recipe's health and environmental impact [22].

- Accelerating R&D and Identifying Synergies: AI is strengthening its grip on food R&D by accelerating product development, predicting trends, and uncovering novel ingredient combinations that promote synergistic health effects [24]. AI can identify patterns and relationships in the scientific literature that human researchers might miss.

Quantitative Performance of NLP in Food Analysis

Table 1: Performance of NLP and Machine Learning Models in Food Analysis Tasks [23]

| Task | Model/Method | Performance Metrics | Comparative Method & Performance |

|---|---|---|---|

| Food Categorization | Pretrained Language Model (XGBoost) | Accuracy: 0.98 (Major categories), 0.96 (Subcategories) | Outperformed Bag-of-Words methods |

| Nutrition Quality Prediction | Pretrained Language Model | R²: 0.87, MSE: 14.4 | Bag-of-Words (R²: 0.72-0.84; MSE: 30.3-17.6) |

| Nutrition Quality Prediction | Structured Nutrition Facts (Machine Learning) | R²: 0.98, MSE: 2.5 | Superior to text-based methods when data is available |

Experimental Protocols

Protocol 1: NLP-Driven Ingredient-Disease Association Mining

This protocol details the process of extracting potential functional ingredient-disease relationships from scientific literature.

1. Objective: To systematically identify and quantify relationships between specific food-derived bioactive compounds and health outcomes from a large corpus of scientific abstracts and full-text articles.

2. Materials and Reagents

- Data Sources: PubMed/MEDLINE, Scopus, Web of Science, Cochrane Library, Patents (USPTO, WIPO).

- Computing Environment: High-performance computing cluster or cloud instance with sufficient RAM (≥32 GB) for processing large datasets.

- Software & Libraries: Python 3.8+, Scikit-learn, SpaCy, NLTK, Transformers (Hugging Face), TensorFlow/PyTorch.

3. Methodology

1. Data Acquisition & Corpus Creation:

- Use APIs (e.g., PubMed E-utilities) to download abstracts and metadata using keyword strings (e.g., ("flavonoid" OR "polyphenol") AND ("CVD" OR "cardiovascular")).

- For full-text analysis, access open-access repositories (PubMed Central) or use publisher APIs where subscriptions exist.

- Store results in a structured database (e.g., SQLite, PostgreSQL) with fields for PMID, title, abstract, publication_date, journal, and authors.

2. Named Entity Recognition (NER):

- Implement a pre-trained biomedical NER model (e.g., en_core_sci_md from SciSpaCy) to identify and extract entities.

- Define entity types: BIOACTIVE_COMPOUND (e.g., curcumin, epigallocatechin gallate), DISEASE (e.g., metabolic syndrome, osteoporosis), GENE (e.g., TNF, IL6), and PHYSIOLOGICAL_PROCESS (e.g., inflammation, oxidative stress).

- Validate and fine-tune the NER model on a manually annotated gold-standard dataset of 500-1000 sentences for domain-specific accuracy.

3. Relationship Extraction:

- Apply a rule-based model to parse dependency trees and identify sentences where a BIOACTIVE_COMPOUND entity and a DISEASE entity are connected by a specific action verb (e.g., "reduces," "inhibits," "ameliorates," "prevents").

- Train a supervised relation classification model (e.g., based on BERT) using a dataset of labeled sentences (e.g., "Curcumin reduces inflammation in arthritis"). Use a 80/20 train-test split.

4. Knowledge Graph Construction:

- Create a network where nodes are entities (BIOACTIVE_COMPOUND, DISEASE, GENE) and edges are the extracted relationships.

- Use a graph database (e.g., Neo4j) for storage and querying. Weight edges based on the co-occurrence frequency and the confidence score from the relation classifier.

- Perform network analysis to identify hub nodes (key bioactives or conditions) and communities of closely related entities.

4. Data Analysis

- Calculate the Jaccard Index or Pointwise Mutual Information (PMI) to quantify the strength of association between a compound and a disease across the corpus.

- Use Centrality Algorithms (e.g., PageRank) on the knowledge graph to identify the most influential bioactive compounds based on their connections to multiple diseases and pathways.

Protocol 2: Predictive Modeling for Ingredient Synergy

This protocol leverages machine learning on structured clinical and omics data to predict synergistic interactions between functional ingredients.

1. Objective: To build a predictive model that identifies ingredient pairs or combinations with a high probability of exhibiting synergistic health effects, based on their compositional and target pathway profiles.

2. Materials and Reagents

- Data Sources: Clinical trial databases (ClinicalTrials.gov), food composition databases (USDA FoodData Central, Phenol-Explorer), bioactivity databases (CMAUP, TCMID), transcriptomic/proteomic data repositories (GEO, PRIDE).

- Software & Libraries: Python 3.8+, Pandas, NumPy, Scikit-learn, XGBoost, SHAP, Matplotlib.

3. Methodology

1. Data Compilation and Feature Engineering:

- Ingredient Profiling: For each ingredient, compile a feature vector including:

- Chemical Features: Concentrations of key bioactive compounds (from food composition DBs).

- Bioactivity Features: Target information from bioactivity DBs (e.g., pKi values for receptors, enzymes).

- Pathway Features: Binary vector indicating association with KEGG/GO pathways (e.g., NF-kB signaling, antioxidant activity).

- Synergy Labeling:

- Label ingredient pairs as "synergistic" (1) or "non-synergistic" (0) based on evidence from literature (e.g., systematic reviews) or pre-clinical experimental data (e.g., combination index <1 in cell assays).

2. Model Training and Validation:

- Use a tree-based ensemble model like XGBoost, which handles non-linear relationships well.

- Input features are the concatenated feature vectors of two ingredients.

- Perform an 80/20 stratified split for training and testing. Use 5-fold cross-validation on the training set for hyperparameter tuning (e.g., max_depth, learning_rate, n_estimators).

- Evaluate model performance on the held-out test set using Accuracy, Precision, Recall, F1-Score, and AUC-ROC.

3. Model Interpretation and Hypothesis Generation:

- Apply SHAP (SHapley Additive exPlanations) analysis to interpret the model's output and identify which chemical features, bioactivities, or pathway co-targeting are most predictive of synergy.

- The top predictions from the model form testable hypotheses for in vitro or clinical validation.

4. Data Analysis

- Calculate the Combination Index (CI) for validation experiments using the Chou-Talalay method, where CI < 1 indicates synergy, CI = 1 indicates additivity, and CI > 1 indicates antagonism.

Table 2: Example Feature Set for an Ingredient (e.g., Turmeric Extract)

| Feature Category | Feature Name | Value | Data Source |

|---|---|---|---|

| Chemical Composition | Curcuminoids (mg/g) | 950 | Phenol-Explorer, In-house QC |

| Volatile Oils (%) | 5 | ||

| Bioactivity Targets | NF-kB Inhibition (pIC50) | 6.2 | ChEMBL, CMAUP |

| COX-2 Inhibition (pIC50) | 5.8 | ||

| Antioxidant (ORAC μmol TE/g) | 12000 | ||

| Pathway Association | Inflammation | 1 (True) | KEGG, GO |

| Apoptosis | 1 (True) | ||

| Oxidative Stress | 1 (True) |

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Reagents and Resources for NLP-Driven Food Formulation Research

| Item/Tool Name | Function/Application | Specifications & Notes |

|---|---|---|

| SciSpaCy Python Package | Domain-specific NLP for biomedical text processing. | Includes pre-trained models for NER and entity linking on biomedical data. Prefer en_core_sci_md model. |

| Transformers Library (Hugging Face) | Access to state-of-the-art pretrained language models (e.g., BERT, BioBERT). | Use BioBERT for superior performance on biological text. Essential for relationship extraction. |

| USDA FoodData Central | Authoritative source for food composition data. | Provides quantitative data on nutrients and bioactive compounds for feature engineering. |

| KEGG PATHWAY Database | Repository of manually drawn pathway maps for metabolism and cellular processes. | Used to map ingredient bioactivities to biological pathways for synergy prediction. |

| Neo4j Graph Database | Native graph database for storing and querying knowledge graphs. | Enables complex queries across extracted ingredient-disease-pathway relationships. |

| SHAP (SHapley Additive exPlanations) | Game-theoretic approach to explain output of any machine learning model. | Critical for interpreting "black box" models and identifying drivers of predicted synergy. |

The integration of NLP and AI provides a powerful, data-driven foundation for advancing functional food research. The protocols outlined herein enable the systematic mining of scientific literature for ingredient-disease associations and the predictive modeling of ingredient synergy. This approach moves formulation beyond empirical tradition towards a precision science, capable of discovering novel, synergistic combinations that can be validated clinically. As these technologies mature, they promise to significantly shorten development cycles and enhance the efficacy of functional food products designed to improve public health.

Application Notes

Scientific Rationale and Background

The integration of artificial intelligence (AI) into functional food research represents a paradigm shift from traditional, population-based dietary approaches to precision nutrition. Predictive modeling leverages AI to analyze complex, multi-modal data, creating a foundational link between specific food formulations, dynamic biomarker responses, and ultimate health outcomes [25]. This approach is central to a new model of proactive health management, which aims to prevent disease onset or delay its progression by identifying early health risks and implementing targeted, nutritional interventions [25].

The efficacy of this methodology is driven by advancements in biomarker science. Contemporary detection platforms—such as single-cell sequencing, high-throughput proteomics, and metabolomics—generate comprehensive molecular profiles [25]. When these diverse data streams are fused using multi-modal data integration techniques, they create a robust foundation for predictive models that can capture complex, non-linear relationships often missed by traditional statistical methods [25]. For instance, the integration of multi-omics data has been shown to improve early diagnosis specificity for conditions like Alzheimer's disease by 32%, providing a crucial window for intervention [25].

Key Applications and Use Cases

Predictive modeling of biomarker responses to functional food formulations has transformative potential across several key health domains, including those targeted by leading commercial products [26].

Table: Primary Application Domains for Predictive Modeling in Functional Foods

| Application Domain | Target Biomarkers | Exemplary Functional Ingredients | Modeling Objective |

|---|---|---|---|

| Immunity Boosting [26] | Vitamin D serum levels, White blood cell counts, Inflammatory cytokines (e.g., IL-6) | Vitamins C & D, Zinc, Probiotics | To predict the modulation of immune cell activity and reduction of inflammation markers. |

| Digestive Health Support [26] | Gut microbiome diversity (e.g., 16S rRNA), Short-chain fatty acids (SCFAs), Intestinal permeability markers | Dietary fibers (e.g., Inulin), Probiotics (e.g., Lactobacillus, Bifidobacterium) | To forecast improvements in gut flora composition and reinforcement of gut barrier integrity. |

| Weight Management & Satiety [26] | Ghrelin, Leptin, Peptide YY (PYY), Blood glucose, Insulin | High-protein blends, Soluble fiber (e.g., Beta-glucan) | To model hormonal shifts that promote satiety and predict postprandial glycemic responses. |

| Cognitive Enhancement [26] | BDNF levels, Inflammatory markers (CRP), Functional MRI (fMRI) connectivity | Omega-3 fatty acids (DHA/EPA), Flavonoids, Phospholipids | To predict improvements in neuronal connectivity and reductions in neuroinflammation. |

Technical Framework and Workflow

The process of linking formulations to biomarker responses involves a structured, iterative pipeline that combines high-quality data acquisition, advanced computational modeling, and clinical validation. The core technical workflow can be visualized as a continuous cycle of data integration and model refinement.

The following diagram illustrates the core closed-loop workflow for developing and validating AI-driven predictive models, from initial data acquisition to final clinical application.

The Scientist's Toolkit: Research Reagent Solutions

The experimental protocols in this field rely on a suite of essential reagents and technologies for precise biomarker analysis and data generation.

Table: Essential Research Reagents and Platforms for Biomarker Analysis

| Reagent / Platform | Primary Function | Application Context |

|---|---|---|

| LC–MS/MS (Liquid Chromatography–Tandem Mass Spectrometry) [25] | High-sensitivity identification and quantification of small molecules and metabolites. | Targeted metabolomic profiling for nutritional intervention studies. |

| ELISA Kits (Enzyme-Linked Immunosorbent Assay) [25] | Quantify specific protein biomarkers (e.g., cytokines, hormones) in serum/plasma. | Measuring inflammatory markers or satiety hormones in response to a functional ingredient. |

| RNA-seq Reagents [25] | Profile global gene expression (transcriptome) from tissue or blood samples. | Assessing molecular-level impact of a formulation on biological pathways. |

| 16S rRNA Sequencing Kits [25] | Characterize bacterial community composition and diversity. | Evaluating the effect of prebiotics or probiotics on gut microbiome. |

| DNA Methylation Arrays [25] | Genome-wide analysis of epigenetic modifications. | Investigating how nutritional compounds influence gene regulation. |

| Wearable Device Data Streams (e.g., CGM) [25] | Continuous, real-time collection of physiological and behavioral data. | Providing dynamic, longitudinal data on glucose levels, activity, and sleep for model input. |

Experimental Protocols

Protocol Title

A Randomized, Controlled, Double-Blind Trial to Evaluate the Efficacy of a Novel Prebiotic-Probiotic Synbiotic Formulation on Gut Microbiome Diversity and Inflammatory Biomarkers in Adults with Metabolic Syndrome.

Study Design and Rationale

This protocol outlines a prospective, randomized, double-blind, placebo-controlled trial—the gold standard for generating high-quality clinical evidence [27]. The primary rationale is to systematically establish a causal link between a defined functional food formulation and a cascade of biomarker responses, thereby validating a predictive AI model for this intervention. The study is designed to be monocentric to ensure consistency in sample collection and analysis, though it can be scaled to a multicentric design in subsequent validation phases [27].

Primary and Secondary Objectives and Endpoints

All study variables and endpoints are selected for their relevance to the hypothesized mechanism of action and their suitability for integration into the predictive model.

Table: Study Objectives and Corresponding Endpoints

| Objective Type | Description | Endpoint / Measured Variable |

|---|---|---|

| Primary Objective | To assess the change in gut microbiome alpha-diversity from baseline to 12 weeks. | Shannon Index calculated from 16S rRNA sequencing data of stool samples. |

| Secondary Objective 1 | To evaluate the change in systemic inflammation. | High-sensitivity C-reactive Protein (hs-CRP) levels in serum, measured via ELISA. |

| Secondary Objective 2 | To assess the change in gut barrier function. | Serum Zonulin levels, measured via ELISA. |

| Secondary Objective 3 | To monitor changes in short-chain fatty acid (SCFA) production. | Fecal Acetate, Propionate, and Butyrate concentrations, measured via GC-MS. |

| Safety Objective | To monitor the incidence of adverse gastrointestinal events. | Subject-reported symptoms collected via structured daily diary. |

Visits and Examinations Schedule

The study timeline is structured to capture acute, intermediate, and longer-term biomarker dynamics, providing rich, longitudinal data for model training.

The following diagram maps the participant journey and key data collection points throughout the study, from initial screening to final follow-up.

Study Population and Sample Size

- Inclusion Criteria: Adults aged 30-65 years; diagnosis of Metabolic Syndrome as defined by the International Diabetes Federation criteria; stable weight (±5 kg in prior 3 months); willingness to maintain current diet and physical activity levels.

- Exclusion Criteria: Use of antibiotics or probiotics within 8 weeks of screening; history of inflammatory bowel disease; active autoimmune condition; use of immunosuppressant medications; pregnancy or lactation.

- Sample Size Justification: A sample size of 100 participants (50 per arm) is calculated to provide 90% power to detect a significant difference in the Shannon Index (primary endpoint) with an effect size of 0.8 and a two-sided alpha of 0.05, accounting for a 15% anticipated dropout rate.

Biomarker Data Acquisition and Analysis Methods

This section details the specific methodologies for all key experiments and biomarker assays cited in the endpoints table [27].

Stool Sample Collection and 16S rRNA Sequencing for Microbiome Analysis:

- Materials: Stool DNA extraction kit, 16S rRNA gene amplification primers (e.g., V3-V4 region), library preparation kit, high-throughput sequencer (e.g., Illumina MiSeq).

- Protocol: Stool samples will be collected by participants using home-collection kits and immediately frozen at -20°C before transport to the lab for storage at -80°C. DNA will be extracted using a standardized commercial kit. The hypervariable V3-V4 region of the 16S rRNA gene will be amplified via PCR, and libraries will be prepared and sequenced on the Illumina MiSeq platform to generate paired-end reads. Bioinformatic analysis (using QIIME2 or Mothur) will include quality filtering, denoising, chimera removal, amplicon sequence variant (ASV) calling, and taxonomic assignment against the SILVA database. The Shannon Index will be calculated to measure alpha-diversity.

Serum Inflammatory Biomarker Quantification via ELISA:

- Materials: Commercial human hs-CRP and Zonulin ELISA kits, microplate reader, precision pipettes.

- Protocol: Fasting blood samples will be collected in serum separator tubes, allowed to clot for 30 minutes, and centrifuged at 2,000 x g for 15 minutes. The separated serum will be aliquoted and stored at -80°C until batch analysis. All samples from a single participant will be analyzed on the same plate to minimize inter-assay variability. The manufacturer's instructions will be followed precisely. Standard curves will be generated for each plate, and sample concentrations will be interpolated from the curve. All samples will be run in duplicate.

Short-Chain Fatty Acid (SCFA) Analysis by Gas Chromatography-Mass Spectrometry (GC-MS):

- Materials: GC-MS system, capillary GC column, internal standards (e.g., deuterated SCFAs), organic solvents.

- Protocol: Fecal samples will be homogenized in a defined weight/volume ratio of acidified water. An internal standard will be added to correct for extraction efficiency. SCFAs will be extracted using diethyl ether. The ether extract will be injected into the GC-MS system. Separation will be achieved using a polar capillary column, and SCFAs will be quantified using selective ion monitoring (SIM) mode. Concentrations will be determined by comparing the peak areas of the samples to those of a calibrated standard curve.

Data Integration and Predictive Model Construction

The data from all assays will be integrated into a unified dataset for model development [25].

- Data Fusion: Clinical data, microbiome ASV tables, SCFA concentrations, and inflammatory biomarker levels will be merged using participant ID and time point as keys.

- AI Model Training: A machine learning pipeline will be implemented, starting with feature selection (e.g., using recursive feature elimination) to identify the most predictive biomarkers. Algorithms such as Random Forest, Gradient Boosting, or regularized regression (LASSO) will be trained on the baseline and longitudinal data from the active arm to predict endpoint outcomes (e.g., final hs-CRP level or change in Shannon Index).

- Model Interpretation: Feature importance scores from the model will be analyzed to identify which formulation-induced biomarker changes were most predictive of the positive health outcomes, thereby elucidating the potential mechanism of action and generating hypotheses for future research.

The global food system faces unprecedented challenges, including the need to feed a population projected to reach nearly 10 billion by 2050 while addressing environmental sustainability, health concerns, and shifting consumer preferences [4]. Traditional food product development relies on iterative, trial-and-error approaches that are time-consuming, expensive, and inefficient, often requiring dozens of cycles to develop formulations, probe texture, prepare samples, and survey consumers [4]. This slow pace of innovation is insufficient to meet urgent demands for transformative changes in our food systems.

Generative Artificial Intelligence (AI) represents a paradigm shift in food formulation, enabling the creation of novel recipes and product formulations directly from natural language prompts [4]. By leveraging advanced machine learning techniques, including transformer-based models, generative adversarial networks (GANs), and reinforcement learning, generative AI can efficiently screen massive multimodal parameter spaces to identify promising ingredient combinations that meet specific nutritional, sensory, and sustainability constraints [14] [4]. This approach is particularly valuable for developing functional foods—products designed to provide specific health benefits beyond basic nutrition—within the broader context of AI-driven food research.

The integration of generative AI in food formulation accelerates the innovation cycle and democratizes discovery by making advanced formulation capabilities accessible to researchers and food scientists without extensive computational backgrounds [4]. By simply describing desired product characteristics in natural language, scientists can generate potential formulations, predict their properties, and optimize them for specific functional properties, thereby bridging the gap between human creativity and data-driven computational power.

Current State of Generative AI in Food Formulation

Defining Generative AI in the Food Context

Generative AI represents a significant advancement over traditional non-generative AI approaches in food science. While non-generative AI focuses on optimization, discovery, and prediction based on existing data, generative AI creates entirely new formulations, textures, and flavor combinations that resemble but are not identical to training data [4]. This creative capacity distinguishes generative AI as a transformative technology for novel food formulation.

The fundamental architecture of generative AI systems for food formulation typically involves several core components: a natural language processing (NLP) interface to interpret researcher prompts, a knowledge base of food science principles and ingredient functionalities, and generative models that produce novel combinations based on learned patterns and constraints [1] [4]. These systems can generate output in various formats, including weighted ingredient lists, processing parameters, and predicted sensory profiles, providing researchers with comprehensive starting points for further development.

Comparative Analysis of AI Approaches in Food Science

Table 1: Comparison of AI Approaches in Food Formulation Research

| AI Approach | Primary Function | Common Algorithms | Food Science Applications | Limitations |

|---|---|---|---|---|

| Non-Generative AI | Optimization, discovery, and prediction | Random forests, XGBoost, CNNs | Ingredient selection, quality control, sensory prediction | Limited to analysis of existing data patterns |

| Generative AI | Creation of novel formulations | GANs, Transformers, RNNs | Novel recipe generation, ingredient substitution, flavor creation | Requires extensive training data, validation needed |

| Hybrid Systems | Combined analysis and generation | Reinforcement learning, federated learning | Personalized nutrition, adaptive formulation | Increased complexity, computational demands |

Technical Foundations of Generative AI for Formulation

Generative AI systems for food formulation leverage several sophisticated machine-learning architectures, each with distinct strengths and applications. Transformer-based models, stemming from the "Attention is All You Need" framework, excel at handling vast datasets and grasping context, which is essential for coherent recipe generation that balances multiple constraints [28]. These models can process natural language prompts and generate structured formulations while considering complex relationships between ingredients, processing methods, and final product properties.

Generative Adversarial Networks (GANs) employ a dual architecture comprising a generator that creates formulations and a discriminator that assesses their quality and feasibility [28]. This adversarial process enables the iterative refinement of generated formulations until they are indistinguishable from human-created recipes. GANs are particularly valuable for creating novel flavor combinations and texture profiles that meet specific functional criteria.

Recurrent Neural Networks (RNNs), particularly Long Short-Term Memory (LSTM) networks, process sequential data and utilize memory cells to remember past inputs, making them suitable for predicting recipe sequences and procedural steps [28]. These architectures are effective at capturing the temporal dependencies in food preparation processes and multi-step formulation development.

Methodology: Implementing Generative AI for Formulation Design

Data Requirements and Preparation

The development of effective generative AI models for food formulation requires comprehensive, high-quality datasets that capture the complex relationships between ingredients, processing methods, and final product properties. The performance of these models is directly correlated with the breadth, depth, and quality of the training data [4] [29].

Table 2: Essential Data Types for Training Generative AI Formulation Models

| Data Category | Specific Data Types | Source Examples | Importance for Model Performance |

|---|---|---|---|

| Ingredient Properties | Chemical composition, molecular structure, functional properties | USDA FoodData Central, FooDB | Enables prediction of ingredient interactions and compatibility |

| Sensory Profiles | Taste, odor, texture measurements | USDA Flavor Database, GNPS | Allows alignment of formulations with target sensory experiences |

| Nutritional Information | Macronutrient and micronutrient profiles, bioavailability | USDA SR Legacy, food labels | Ensures nutritional targets are met in generated formulations |

| Formulation Examples | Existing recipes, product formulations | proprietary industry data, scientific publications | Provides patterns for realistic and feasible formulations |

| Processing Parameters | Time, temperature, shear rates, extrusion parameters | scientific literature, patent databases | Encomes generation of feasible manufacturing instructions |

A critical challenge in this domain is the relative scarcity of data correlating formulations with rheology, texture, and flavor properties [4]. While nutritional profiles are relatively straightforward to predict from ingredient lists, sensory characteristics present greater complexity due to the nuanced interplay of chemical components and human perception. This limitation is particularly pronounced for texture prediction, which has seen comparatively less research interest than taste and odor [29].

Natural Language Processing for Prompt Interpretation

The interpretation of researcher prompts requires sophisticated natural language processing (NLP) capabilities that transform informal descriptions into structured formulation constraints. Effective prompt processing involves several key steps: entity recognition to identify relevant ingredients, processes, and product attributes; constraint extraction to determine nutritional, sensory, and compositional requirements; and intent classification to discern the researcher's primary objectives [30].

Advanced NLP models, particularly fine-tuned transformer architectures, can understand contextual relationships within prompts, such as the distinction between "high-protein, low-carb" and "low-protein, high-carb" formulations. This nuanced understanding enables the generation of formulations that accurately reflect researcher intent, even when expressed in informal or incomplete language [30] [28]. The integration of domain-specific knowledge graphs further enhances this capability by incorporating food science principles and ingredient compatibility rules.

Formulation Generation and Optimization Workflow

The core formulation generation process integrates multiple AI approaches to transform interpreted prompts into viable formulations. This workflow typically begins with constraint satisfaction algorithms that identify ingredient combinations meeting specified requirements, followed by generative models that propose novel formulations within the solution space [1] [4].

Following initial generation, optimization algorithms refine formulations against multiple objectives, including cost minimization, nutritional optimization, and environmental impact reduction. Multi-objective optimization approaches, such as Pareto front analysis, enable researchers to balance competing priorities and select formulations that represent optimal trade-offs between different criteria [14] [1]. This optimization process can incorporate predictive models for sensory properties, shelf stability, and consumer acceptance to ensure practical viability.

Experimental Protocols for Validation

In Silico Formulation Validation Protocol

Before proceeding to physical prototyping, generated formulations should undergo comprehensive computational validation to assess their feasibility and potential performance. This protocol outlines a systematic approach for in silico validation of AI-generated formulations.

Materials:

- Computational infrastructure capable of running predictive models

- Database of ingredient properties and interactions

- Predictive models for sensory attributes and physicochemical properties

Procedure:

- Ingredient Compatibility Analysis: Screen generated formulations for known incompatible ingredient combinations using rule-based systems trained on food science literature.

- Nutritional Profile Verification: Calculate predicted nutritional composition based on ingredient quantities and compare against target nutritional specifications.

- Sensory Property Prediction: Utilize trained machine learning models, such as graph neural networks for taste compounds or deep learning models for texture, to predict sensory characteristics [29].

- Stability Assessment: Apply physicochemical models to predict shelf stability, water activity, and potential degradation pathways.

- Process Feasibility Evaluation: Assess manufacturing feasibility by comparing required processes against available equipment capabilities.

Quality Control: Establish thresholds for acceptability across all validation metrics. Formulations failing to meet these thresholds should be returned for regeneration with additional constraints. Document all validation results for traceability and model improvement.

Physical Prototyping and Analysis Protocol