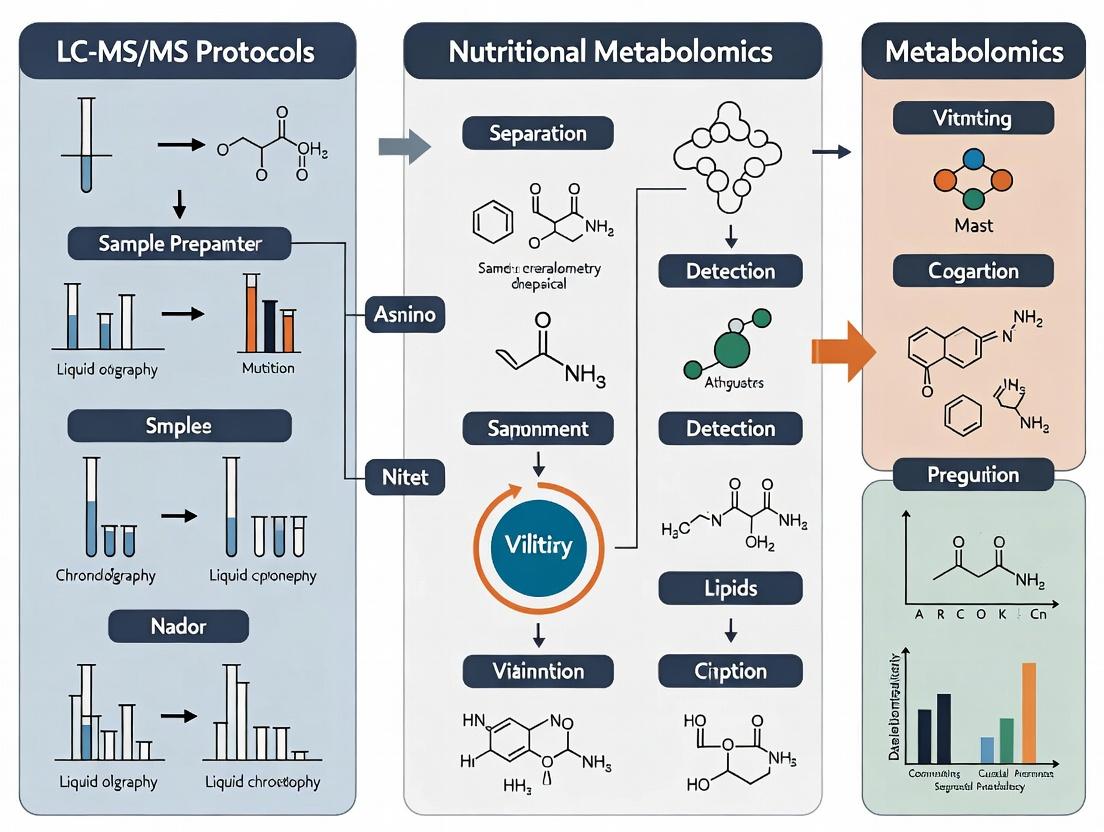

Comprehensive LC-MS/MS Protocols for Nutritional Metabolomics in Human Plasma: From Sample Prep to Biomarker Discovery

This article provides a detailed, step-by-step guide for researchers and scientists implementing LC-MS/MS-based nutritional metabolomics in human plasma.

Comprehensive LC-MS/MS Protocols for Nutritional Metabolomics in Human Plasma: From Sample Prep to Biomarker Discovery

Abstract

This article provides a detailed, step-by-step guide for researchers and scientists implementing LC-MS/MS-based nutritional metabolomics in human plasma. It covers the foundational principles of why plasma is the matrix of choice for assessing dietary intake and nutritional status, followed by comprehensive methodological protocols for sample collection, preparation, chromatography, and tandem mass spectrometry analysis. The guide dedicates significant attention to common troubleshooting scenarios and optimization strategies for sensitivity and reproducibility. Finally, it addresses critical validation parameters, quality control frameworks, and compares LC-MS/MS to alternative analytical platforms. This resource aims to equip professionals in research and drug development with the practical knowledge to generate robust, quantitative metabolomic data for discovering diet-related biomarkers and understanding metabolic pathways.

Nutritional Metabolomics 101: Why Human Plasma is Key to Decoding Diet-Health Interactions

Nutritional metabolomics is defined as the comprehensive profiling of metabolites in biological samples to understand the metabolic response to dietary intake, thereby bridging dietary patterns with measurable metabolic phenotypes. Within human plasma research, LC-MS/MS has become the cornerstone technology due to its high sensitivity, specificity, and ability to quantify a broad spectrum of nutritional biomarkers, from polar vitamins to complex lipids.

Key Applications:

- Biomarker Discovery: Identifying objective biomarkers of food intake (e.g., alkylresorcinols for whole grain, proline betaine for citrus) to move beyond dietary recall inaccuracies.

- Mechanistic Insights: Elucidating metabolic pathways perturbed by specific nutrients or dietary patterns (e.g., saturated fat intake and branched-chain amino acid metabolism).

- Personalized Nutrition: Stratifying individuals based on their metabolic phenotype to predict differential responses to dietary interventions.

- Drug-Nutrient Interactions: Assessing how dietary components modulate drug metabolism pathways and efficacy.

Core Experimental Protocols

Protocol 1: Targeted LC-MS/MS for Quantification of Nutritional Metabolites in Human Plasma

Objective: To precisely quantify a panel of 40 known nutritional biomarkers, including vitamins, carotenoids, and fatty acids.

Materials:

- Sample: EDTA or heparin human plasma (100 µL per analysis).

- Internal Standards: Stable isotope-labeled analogs for each analyte class (e.g., d6-α-Tocopherol, 13C3-carnitine).

- Reagents: HPLC-grade methanol, acetonitrile, water, methyl-tert-butyl ether (MTBE), formic acid, ammonium acetate.

Procedure:

- Sample Preparation (Protein Precipitation & Lipid Extraction):

- Thaw plasma samples on ice.

- Aliquot 100 µL of plasma into a 1.5 mL microcentrifuge tube.

- Add 10 µL of the mixed internal standard working solution.

- Vortex for 10 seconds and incubate for 10 minutes at room temperature.

- Add 300 µL of cold methanol (-20°C) to precipitate proteins. Vortex vigorously for 1 minute.

- For lipid-soluble analytes (e.g., vitamins A, E, carotenoids), add 1 mL of MTBE, vortex for 10 minutes, and centrifuge at 14,000 x g for 10 minutes at 4°C. Transfer the upper organic layer to a new tube and evaporate under nitrogen. Reconstitute in 100 µL of methanol/dichloromethane (1:1).

- For water-soluble analytes, centrifuge the methanol-plasma mixture at 14,000 x g for 15 minutes at 4°C. Transfer the supernatant to a new vial for analysis.

LC-MS/MS Analysis:

- Chromatography: Reversed-phase C18 column (2.1 x 100 mm, 1.7 µm). Mobile Phase A: 0.1% formic acid in water with 5 mM ammonium acetate. Mobile Phase B: 0.1% formic acid in acetonitrile.

- Gradient: 5% B to 95% B over 12 minutes, hold for 3 minutes, re-equilibrate for 5 minutes. Flow rate: 0.35 mL/min. Column temperature: 40°C.

- Mass Spectrometry: Triple quadrupole MS operated in multiple reaction monitoring (MRM) mode. Electrospray ionization (ESI) positive/negative switching. Source parameters: Capillary voltage 3.0 kV, source temperature 150°C, desolvation temperature 500°C, desolvation gas flow 800 L/h.

- Data Acquisition: Optimized MRM transitions, dwell times (≥20 ms), and collision energies for each analyte and its corresponding internal standard are defined in the method table.

Data Processing:

- Quantify using the internal standard method. Generate calibration curves (1-1000 ng/mL) for each analyte using analyte/IS peak area ratios. Apply linear regression with 1/x weighting.

Protocol 2: Untargeted LC-MS/MS for Phenotype Discovery

Objective: To perform global metabolic profiling for hypothesis generation.

Procedure:

- Sample Preparation: As per Protocol 1, but without class-specific extraction. Use a simple methanol precipitation. Pool equal aliquots of all samples to create a quality control (QC) sample.

- LC-MS/MS Analysis: Utilize high-resolution mass spectrometry (e.g., Q-TOF).

- Perform both reversed-phase (C18) and hydrophilic interaction liquid chromatography (HILIC) separations to capture a wider metabolite range.

- Acquire data in data-independent acquisition (DIA) or information-dependent acquisition (IDA) mode with MS/MS fragmentation.

- Data Processing:

- Use software (e.g., MS-DIAL, XCMS) for peak picking, alignment, and compound identification via spectral matching to public libraries (e.g., MassBank, HMDB).

- Normalize data to total ion count or internal standards, then perform multivariate statistical analysis (PCA, PLS-DA) to identify differentially abundant features.

Data Presentation

Table 1: Key Nutritional Biomarkers and Their Analytical Parameters in Human Plasma

| Analyte Class | Example Metabolites | Dietary Source | Typical Plasma Concentration (Fasting) | MRM Transition (Quantifier) | Retention Time (min) | Internal Standard |

|---|---|---|---|---|---|---|

| Carotenoids | β-Carotene, Lutein | Carrots, Leafy greens | 0.1 - 0.8 µmol/L | 537.4 > 445.4 (ESI+) | 8.2 | d6-β-Carotene |

| Fat-Soluble Vitamins | α-Tocopherol (Vit E) | Nuts, Seeds | 15 - 40 µmol/L | 431.4 > 165.1 (ESI+) | 7.5 | d6-α-Tocopherol |

| Water-Soluble Vitamins | Vitamin B5 (Pantothenate) | Meat, Whole grains | 0.5 - 2.0 µmol/L | 220.1 > 90.0 (ESI+) | 2.1 | 13C3-Pantothenate |

| Phytochemicals | Alkylresorcinols C17:0 | Whole grain rye/wheat | 10 - 100 nmol/L | 363.3 > 181.1 (ESI+) | 9.8 | d5-Alkylresorcinol C19:0 |

| Fatty Acids | Omega-3 EPA | Fatty fish | 50 - 150 µmol/L (total) | 301.2 > 257.2 (ESI-) | 6.7 | d5-EPA |

Table 2: Typical LC-MS/MS System Suitability Criteria for Nutritional Metabolomics

| Parameter | Acceptance Criteria | Purpose |

|---|---|---|

| Retention Time Shift | ≤ ± 0.1 min | Chromatographic reproducibility |

| Peak Width (at 50%) | ≤ 0.2 min | Adequate chromatographic resolution |

| Signal/Noise Ratio (Low Calibrator) | ≥ 10:1 | Assay sensitivity |

| QC Sample Precision (CV%) | ≤ 15% (≤ 20% for LLOQ) | Intra-batch reproducibility |

| Calibration Curve R² | ≥ 0.99 | Linearity of response |

Diagrams

Workflow from Diet to Metabolic Phenotype

BCAA Metabolism Links Diet to Insulin Phenotype

The Scientist's Toolkit

| Research Reagent / Solution | Function in Nutritional Metabolomics |

|---|---|

| Stable Isotope-Labeled Internal Standards (e.g., 13C, 15N, d-) | Corrects for matrix effects and losses during sample prep; essential for accurate quantification. |

| Dextran-Coated Charcoal-Stripped Human Plasma | Provides an analyte-free matrix for preparing calibration standards in a matched biological background. |

| SPE Cartridges (Mixed-Mode, C18, HLB) | For selective cleanup and enrichment of specific metabolite classes (e.g., acids, lipids) from plasma. |

| Derivatization Reagents (e.g., Dansyl Chloride) | Enhances detection sensitivity and chromatography of poorly ionizing metabolites (e.g., amines, phenols). |

| Synthetic MRM Standard Kits | Pre-optimized, quantitative standards for targeted panels of nutritional biomarkers (e.g., B vitamins). |

| Quality Control (QC) Plasma Pools | Large-volume, homogeneous pools from representative donors for long-term method performance monitoring. |

| Mass Spectral Libraries (e.g., NIST, HMDB, MoNA) | Critical for annotating unknown peaks in untargeted workflows based on MS/MS fragmentation patterns. |

The Unique Advantages of Human Plasma as a Metabolic Snapshot

Human plasma serves as a comprehensive, systemic biofluid, providing a dynamic snapshot of an individual's metabolic state. It integrates endogenous metabolic pathways, dietary intake, xenobiotic exposure, and gut microbiota activity, making it an ideal matrix for nutritional metabolomics. Within LC-MS/MS-based research, plasma offers unique advantages: standardized collection protocols, rich quantitative data reflective of systemic physiology, and the ability to correlate metabolite shifts with health outcomes. These Application Notes detail the protocols and considerations for leveraging plasma in nutritional metabolomics studies, framed within robust LC-MS/MS workflows.

Plasma, the cell-free fraction of blood, is in constant equilibrium with tissues and organs. It carries nutrients, hormones, signaling molecules, and waste products, offering a real-time, integrated readout of the body's biochemical status. In nutritional metabolomics, this is critical for assessing dietary biomarker discovery, nutrient status, metabolic flexibility, and the physiological response to interventions. Compared to other biofluids like urine or saliva, plasma provides more stable concentrations of a wide range of low-abundance metabolites and is less subject to transient fluctuations.

Key Quantitative Advantages of Human Plasma

The quantitative profile of human plasma provides a rich data source for metabolomic investigation. Key classes of measurable analytes are summarized below.

Table 1: Key Metabolite Classes in Human Plasma Accessible via LC-MS/MS

| Metabolite Class | Example Analytes | Typical Concentration Range | Primary Information Relevance |

|---|---|---|---|

| Amino Acids & Derivatives | Leucine, Isoleucine, Valine, Tryptophan, Kynurenine | 10-500 µM | Protein metabolism, dietary intake, immune regulation |

| Lipids & Fatty Acids | Non-esterified Fatty Acids (NEFA), Lysophosphatidylcholines (LPC), Acylcarnitines | 0.1-1000 µM (class-dependent) | Energy metabolism, membrane integrity, inflammation |

| Carbohydrates & Intermediates | Glucose, Lactate, Citrate, Succinate | 1-5000 µM | Glycolysis, TCA cycle activity, energy state |

| Bile Acids | Cholic acid, Chenodeoxycholic acid, Glyco-conjugates | 0.01-10 µM | Gut microbiome co-metabolism, lipid digestion |

| Vitamins & Cofactors | Vitamin D metabolites, B vitamins (e.g., B12, Folate) | pM to nM | Nutritional status, enzymatic function |

| Xenobiotics | Pharmaceuticals, Food Bioactives (e.g., polyphenols) | Variable | Drug pharmacokinetics, dietary exposure |

Detailed LC-MS/MS Protocol for Broad-Spectrum Plasma Metabolomics

3.1. Materials & Reagent Solutions (The Scientist's Toolkit) Table 2: Essential Research Reagent Solutions

| Item | Function & Critical Notes |

|---|---|

| Ice-cold Methanol (80%, v/v) | Protein precipitation solvent. High purity (LC-MS grade) is essential to minimize background noise. |

| Internal Standard (IS) Mix | A cocktail of stable isotope-labeled analogs (e.g., 13C, 15N) for key metabolite classes. Corrects for extraction efficiency and MS instrument variability. |

| Ammonium Formate / Formic Acid | Common mobile phase additives for positive ion mode LC-MS. Maintains consistent pH and improves ionization. |

| Ammonium Acetate / Ammonium Hydroxide | Common mobile phase additives for negative ion mode LC-MS. |

| C18 & HILIC Chromatography Columns | Complementary separation mechanisms. C18 for lipids, bile acids; HILIC for polar metabolites (amino acids, sugars). |

| Quality Control (QC) Pooled Plasma Sample | Generated by combining small aliquots of all study samples. Injected repeatedly throughout the run to monitor system stability and for data normalization. |

3.2. Pre-Analytical Protocol: Plasma Collection & Metabolite Extraction

- Blood Collection & Processing: Collect venous blood into EDTA or lithium heparin tubes. Critical: Maintain consistent pre-analytical variables (fasting status, time of day, processing time). Process within 30 minutes by centrifugation at 1500-2000 x g for 10-15 minutes at 4°C. Immediately aliquot plasma and store at -80°C.

- Protein Precipitation Extraction:

- Thaw aliquots on ice.

- Pipette 50 µL of plasma into a pre-chilled microcentrifuge tube.

- Add 150 µL of ice-cold 80% methanol containing the internal standard mix.

- Vortex vigorously for 30 seconds.

- Incubate at -20°C for 1 hour to enhance protein precipitation.

- Centrifuge at 17,000 x g for 15 minutes at 4°C.

- Transfer 150 µL of the clear supernatant to a fresh LC-MS vial.

- Dry under a gentle stream of nitrogen or using a vacuum concentrator.

- Reconstitute in 50 µL of a solvent compatible with your initial LC mobile phase (e.g., water or starting mobile phase). Vortex and centrifuge before injection.

3.3. LC-MS/MS Acquisition Parameters (Example)

- Chromatography: Employ two complementary methods.

- Reversed-Phase (C18): For lipids and less polar metabolites. Gradient: Water/Acetonitrile with 0.1% formic acid.

- HILIC: For polar metabolites. Gradient: Acetonitrile/Water with 10mM ammonium acetate (pH 9.0).

- Mass Spectrometry:

- Ionization: Electrospray Ionization (ESI), positive and negative modes.

- Scan Type: Use a combination of Full Scan (m/z 50-1200) for untargeted discovery and Multiple Reaction Monitoring (MRM) for targeted, high-sensitivity quantification of pre-defined panels.

- Resolution: Typically use a triple quadrupole (QqQ) for quantification or a high-resolution (Q-TOF, Orbitrap) for untargeted profiling.

3.4. Data Processing & Analysis

- Use vendor or open-source software (e.g., MS-DIAL, XCMS) for peak picking, alignment, and deconvolution.

- Normalize data using internal standards and QC-based methods (e.g., LOESS, SERRF).

- Perform statistical analysis (univariate t-tests, ANOVA; multivariate PCA, PLS-DA) to identify significant metabolites.

- Annotate significant features using accurate mass, MS/MS spectra, and retention time matching against databases (HMDB, METLIN).

Visualizing Metabolic Pathways & Workflows

Plasma Integrates Systemic Metabolism for LC-MS Analysis

Plasma Metabolite Extraction Protocol for LC-MS

Plasma Reflects Multiple Metabolic Axes

Within nutritional metabolomics, the simultaneous quantification of core compound classes—vitamins, lipids, amino acids, and microbial metabolites—provides a systems-level view of nutritional status, metabolic flux, and host-microbiome interactions. LC-MS/MS is the cornerstone technology due to its specificity, sensitivity, and ability to handle complex matrices like human plasma. This document presents integrated protocols for the targeted analysis of these analytes, framed within a thesis focused on robust LC-MS/MS workflows for human plasma research.

Key Research Reagent Solutions

| Reagent/Material | Function in Analysis |

|---|---|

| Stable Isotope-Labeled Internal Standards (e.g., 13C, 15N, 2H) | Corrects for matrix effects, ionization efficiency variability, and preparation losses for precise quantification. |

| Methanol (LC-MS Grade) | Protein precipitation agent; ensures high-purity, low-background sample cleanup. |

| Acetonitrile (LC-MS Grade) | Mobile phase component; offers different selectivity compared to methanol for chromatographic separation. |

| Ammonium Formate / Formic Acid (MS Grade) | Mobile phase additives for controlling pH and promoting [M+H]+ ionization in positive electrospray mode. |

| Ammonium Acetate / Acetic Acid (MS Grade) | Mobile phase additives for negative ion mode optimization and alternative buffer system. |

| Solid Phase Extraction (SPE) Plates (e.g., C18, Mixed-Mode) | Enable high-throughput, selective cleanup and concentration of analytes from plasma. |

| Derivatization Reagents (e.g., Dansyl Chloride, APTS) | Enhance ionization efficiency and chromatographic separation of poorly ionizing compounds (e.g., some vitamins). |

| Quality Control (QC) Pooled Plasma | Monitors system stability, reproducibility, and data quality throughout analytical batches. |

Experimental Protocols

Protocol 3.1: Sample Preparation for Comprehensive Profiling

Principle: Simultaneous extraction of metabolites across four core classes with maximum recovery and minimal degradation.

Procedure:

- Thawing: Thaw EDTA plasma samples on ice.

- Aliquoting: Transfer 50 µL of plasma into a pre-cooled 1.5 mL microcentrifuge tube.

- Protein Precipitation: Add 200 µL of ice-cold methanol:acetonitrile (50:50, v/v) containing a cocktail of stable isotope-labeled internal standards for all target analyte classes.

- Vortex & Incubate: Vortex vigorously for 30 seconds, then incubate at -20°C for 30 minutes.

- Centrifugation: Centrifuge at 16,000 × g for 15 minutes at 4°C.

- Collection: Transfer 180 µL of the supernatant to a clean LC-MS vial.

- Evaporation & Reconstitution: Evaporate to dryness under a gentle stream of nitrogen. Reconstitute in 50 µL of initial mobile phase (e.g., 98% Water, 2% Acetonitrile, 0.1% Formic Acid).

- Storage: Place vials in autosampler at 4°C until analysis.

Protocol 3.2: LC-MS/MS Analysis with Polarity Switching

Chromatography Conditions:

- Column: C18 reversed-phase column (e.g., 2.1 x 100 mm, 1.7 µm).

- Mobile Phase A: Water with 0.1% formic acid and 5 mM ammonium formate.

- Mobile Phase B: Acetonitrile with 0.1% formic acid.

- Gradient: 2% B (0-1 min), 2-95% B (1-12 min), 95% B (12-14 min), 95-2% B (14-14.1 min), 2% B (14.1-16 min).

- Flow Rate: 0.4 mL/min.

- Column Temp: 40°C.

- Injection Volume: 5 µL.

Mass Spectrometry Conditions:

- Instrument: Triple quadrupole MS with electrospray ionization (ESI).

- Ionization Mode: Fast polarity switching between positive and negative modes within a single run.

- Source Parameters: Capillary Voltage: ±3.0 kV; Source Temp: 150°C; Desolvation Temp: 500°C; Desolvation Gas Flow: 800 L/hr.

- Data Acquisition: Multiple Reaction Monitoring (MRM). Optimized MRM transitions, collision energies, and cone voltages are pre-defined for each analyte and internal standard. Dwell times adjusted to ensure ≥12 points per peak.

Table 1: Representative Analytical Figures of Merit for Core Compound Classes in Plasma

| Compound Class | Example Analytes | Linear Range (ng/mL) | LLOQ (ng/mL) | Intra-day Precision (%RSD) | Inter-day Precision (%RSD) | Recovery (%) |

|---|---|---|---|---|---|---|

| Fat-Soluble Vitamins | Vitamin A (Retinol), 25-OH Vitamin D3, Vitamin E (α-Tocopherol) | 1 - 500 | 0.5 | 3.2 - 5.8 | 5.1 - 8.7 | 92 - 105 |

| Water-Soluble Vitamins | Vitamin B1 (Thiamine), B6 (Pyridoxal), B9 (Folate), B12 (Cobalamin) | 0.1 - 100 | 0.05 | 4.1 - 7.3 | 6.5 - 10.2 | 88 - 102 |

| Amino Acids | Leucine, Tryptophan, Glutamine, Arginine | 50 - 10,000 | 25 | 2.5 - 4.5 | 3.8 - 6.5 | 95 - 108 |

| Complex Lipids | Phosphatidylcholines (PC), Lysophosphatidylcholines (LPC), Ceramides (Cer) | 10 - 5,000 | 5 | 4.5 - 8.5 | 7.0 - 11.5 | 90 - 103 |

| Microbial Metabolites | Short-Chain Fatty Acids (Butyrate), Indole-3-propionic acid, Trimethylamine N-oxide (TMAO) | 0.5 - 200 | 0.25 | 5.5 - 9.0 | 8.2 - 12.4 | 85 - 98 |

Table 2: Polarity and Key MRM Transitions for Select Analytes

| Analyte | Ionization Polarity | Precursor Ion (m/z) > Product Ion (m/z) | Collision Energy (eV) |

|---|---|---|---|

| 25-OH Vitamin D3 | Positive | 401.3 > 159.1 | 18 |

| Folate (5-MTHF) | Positive | 460.1 > 313.1 | 20 |

| Tryptophan | Positive | 205.1 > 146.1 | 16 |

| Butyric Acid | Negative | 87.0 > 43.0 | 10 |

| PC(34:2) | Positive | 758.6 > 184.1 | 32 |

| TMAO | Positive | 76.1 > 58.1 | 18 |

Visualized Workflows and Pathways

Title: Plasma Metabolite Extraction and LC-MS/MS Workflow

Title: Core Metabolite Interactions in Nutritional Status

Within nutritional metabolomics using LC-MS/MS, the study design fundamentally dictates the validity and scope of biological insights. Cohort, intervention, and cross-sectional designs each offer distinct advantages for profiling human plasma metabolomes, guiding hypothesis generation, and establishing causality in diet-disease relationships.

Design Considerations & Quantitative Comparison

Table 1: Comparative Analysis of Primary Study Designs in Nutritional Metabolomics

| Design Parameter | Prospective Cohort Study | Randomized Controlled Trial (RCT) / Intervention | Cross-Sectional Analysis |

|---|---|---|---|

| Primary Aim | Identify temporal relationships & biomarkers of disease risk. | Establish causal effects of a nutritional intervention. | Snapshot of metabolic associations at a single time point. |

| Timeframe | Long-term (years to decades). | Short to medium-term (weeks to months). | Single time point. |

| LC-MS/MS Sampling | Repeated plasma sampling at baseline and pre-defined intervals/follow-ups. | Pre- and post-intervention sampling; often with run-in/washout phases. | Single plasma sample collection. |

| Key Strength | Assesses long-term diet-metabolite-disease trajectories; real-world relevance. | High internal validity; controls for confounding via randomization. | Logistically simple; rapid hypothesis generation. |

| Major Limitation | Costly, time-consuming; residual confounding. | May lack generalizability; ethical/practical limits on interventions. | Cannot infer causality or temporal sequence. |

| Sample Size Typical Range | 500 - 10,000+ participants. | 20 - 100+ participants per arm. | 100 - 1,000+ participants. |

| Primary Statistical Approach | Time-to-event analysis (Cox regression); mixed models for repeated metabolites. | Paired tests (Wilcoxon, t-test); ANOVA for multi-arm studies. | Correlation analysis; linear/logistic regression. |

| Power in Metabolomics | Powered for clinical endpoints, not for full metabolome discovery (often uses nested case-control). | Powered for specific metabolite changes from intervention. | Often underpowered for high-dimensional discovery without validation cohort. |

Detailed Methodological Protocols for LC-MS/MS Metabolomics

Protocol 2.1: Standardized Plasma Collection & Pre-Analytical Processing for All Designs

Objective: Minimize pre-analytical variation in plasma metabolome profiles. Materials: EDTA or heparin tubes, cryovials, refrigerated centrifuge, -80°C freezer. Procedure:

- Fasting Blood Draw: Collect venous blood following a >8h overnight fast. Use consistent time of day across study.

- Immediate Processing: Centrifuge blood samples at 2,000-2,500 x g for 10-15 minutes at 4°C within 2 hours of collection.

- Plasma Aliquoting: Carefully pipette plasma supernatant into pre-labeled cryovials (typically 50-100 µL aliquots) avoiding the buffy coat.

- Snap-Freezing: Flash-freeze aliquots in liquid nitrogen or a dry ice-ethanol bath.

- Storage: Transfer to -80°C freezer within 1 hour. Maintain consistent freezer conditions. Avoid freeze-thaw cycles.

Protocol 2.2: LC-MS/MS Metabolite Extraction from Human Plasma

Objective: Perform a reproducible protein precipitation and metabolite extraction compatible with hydrophilic interaction liquid chromatography (HILIC) and reversed-phase (RP) LC-MS/MS. Research Reagent Solutions:

- Extraction Solvent: Methanol:Acetonitrile:Water (50:30:20, v/v/v) with 0.1% Formic Acid, chilled to -20°C. Function: Denatures proteins, precipitates macromolecules, and extracts a broad range of polar and semi-polar metabolites.

- Internal Standard Mix: Stable isotope-labeled standards (e.g., amino acids, fatty acids, acylcarnitines) in methanol. Function: Corrects for variability during sample preparation, injection, and ionization.

- Quality Control (QC) Pool: An aliquot prepared by combining equal volumes of all study samples. Function: Monitors instrument stability and data reproducibility throughout the analytical sequence.

Procedure:

- Thaw plasma samples on ice.

- Piper 50 µL of plasma into a pre-cooled 1.5 mL microcentrifuge tube.

- Add 200 µL of chilled extraction solvent and 10 µL of internal standard mix.

- Vortex vigorously for 30 seconds.

- Incubate at -20°C for 60 minutes to complete protein precipitation.

- Centrifuge at 18,000 x g for 15 minutes at 4°C.

- Transfer 180 µL of the supernatant to a clean LC-MS vial with insert.

- Keep vials at 4°C in the autosampler (typically 6°C) for analysis. Inject 5-10 µL for analysis.

Protocol 2.3: Analytical Sequence Design for Large Cohort/Cross-Sectional Studies

Objective: Ensure data quality and correct for instrumental drift in high-throughput analyses. Procedure:

- Conditioning: Inject QC pool sample 5-10 times to condition the LC column and stabilize the MS system.

- Randomization: Inject study samples in a randomized order to avoid batch effects correlated with clinical groups.

- QC Frequency: Inject the QC pool sample after every 6-10 study samples.

- Solvent Blanks: Inject a solvent blank (extraction solvent) after every 20-30 samples to monitor carryover.

- Reference Standards: Inject a mixture of authentic chemical standards at the beginning and end of the sequence to confirm metabolite identity and retention time stability.

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Reagents & Materials for LC-MS/MS Nutritional Metabolomics

| Item | Function & Rationale |

|---|---|

| Stable Isotope-Labeled Internal Standards (SIL-IS) | Distinguishes analyte signal from background; corrects for matrix effects & extraction efficiency. Essential for quantitative accuracy. |

| Dual LC Column Set (e.g., C18 RP & HILIC) | Provides complementary separation: RP for lipids/bile acids; HILIC for polar metabolites (amino acids, sugars). Maximizes metabolome coverage. |

| Mobile Phase Additives (FA, NH4Ac, NH4OH) | Formic Acid (FA) for positive ion mode; Ammonium Acetate (NH4Ac) for both modes; Ammonium Hydroxide (NH4OH) for negative mode. Modulate ionization efficiency. |

| Commercial Metabolite Libraries (e.g., NIST, HMDB) | Spectral reference libraries for compound annotation based on accurate mass, retention time, and MS/MS fragmentation patterns. |

| Processed QC Pool Sample | Evaluates system stability, batch-to-batch variation, and data reproducibility. Critical for post-acquisition data QC. |

| Standard Reference Material (SRM 1950) | NIST plasma-based metabolomics reference material. Allows inter-laboratory comparison and method benchmarking. |

| Liquid Handling Robot | Automates plasma aliquoting, protein precipitation, and derivatization steps to improve throughput and reduce human error. |

Visualized Workflows & Relationships

Within LC-MS/MS protocols for nutritional metabolomics in human plasma research, pre-analytical variability is a predominant source of error, potentially eclipsing analytical imprecision. The integrity of metabolomic data is fundamentally established during sample collection and initial processing. This document details standardized application notes and protocols for managing fasting status, selecting collection tubes, and implementing stabilization strategies to ensure reproducible and biologically relevant results in nutritional intervention and biomarker discovery studies.

Fasting Status Protocols

Standardized Fasting Protocol for Nutritional Metabolomics

Objective: To minimize dietary confounders and establish a metabolically stable baseline for longitudinal studies.

Protocol:

- Duration: A minimum 10-hour overnight fast is required. Water intake is permitted.

- Participant Instructions: Provide written instructions prohibiting all food, caloric beverages, alcohol, and strenuous exercise for 12 hours prior to phlebotomy. Medications/supplements should be taken as usual unless specified by the study protocol.

- Timing: Schedule collections for morning hours (e.g., 7:00 - 9:00 AM) to mitigate circadian effects.

- Verification: Document fasting duration and compliance via questionnaire at time of draw.

- Post-Collection: After the fasting draw, a standardized nutritional challenge (e.g., mixed meal tolerance test) may be administered for dynamic metabolomic profiling, with timed collections at 30, 60, 120, and 180 minutes.

Impact Assessment: Key Metabolite Sensitivity to Fasting

Table 1: Representative Metabolite Concentration Shifts Post-Prandial

| Metabolite Class | Example Metabolite | Fasting Concentration (Approx.) | Post-Prandial Change (at 2h) | Notes for LC-MS/MS |

|---|---|---|---|---|

| Lipids | Triglycerides | 0.5-1.5 mM | Increase 50-200% | Major confounder; requires strict fasting. |

| Bile Acids | Cholic Acid | Low nM range | Increase 5-10 fold | Rapid kinetics; critical for gut metabolism studies. |

| Amino Acids | Branched-Chain Amino Acids (Leu, Ile, Val) | 100-300 µM | Increase 20-40% | Dietary protein sensitive. Stable after 8h fast. |

| Carbohydrates | Glucose | 4.0-5.5 mM | Increase 20-50% | Stabilizes after 10h fast. |

| Ketone Bodies | β-Hydroxybutyrate | 0.1-0.5 mM | Decrease >50% | Sensitive indicator of fasting status. |

Blood Collection Tube Selection & Protocols

Comparative Evaluation of Collection Tubes

Objective: To select tubes that maximize analyte stability and minimize interference for broad-spectrum metabolomic profiling.

Protocol for Tube Comparison Study:

- Simultaneous Draw: Collect blood via a multi-draw adapter into the following tube types (in randomized order):

- Tube A: Lithium Heparin (Plasma, no gel separator).

- Tube B: EDTA (K2 or K3).

- Tube C: Sodium Citrate.

- Tube D: Serum Clot Activator (with gel separator).

- Processing: Invert all tubes gently 8-10 times. Process within 30 minutes of draw.

- Plasma Tubes (A-C): Centrifuge at 2000 x g for 15 minutes at 4°C.

- Serum Tube (D): Allow to clot for 30 minutes at RT, then centrifuge as above.

- Aliquotting: Carefully pipette supernatant (avoiding gel or buffy coat) into pre-labeled cryovials. Flash-freeze in liquid nitrogen within 1 hour of collection. Store at ≤ -80°C.

- LC-MS/MS Analysis: Batch analyze aliquots for a panel of key nutritional metabolites (e.g., free fatty acids, amino acids, vitamins, oxidative stress markers).

Table 2: Collection Tube Suitability for Nutritional Metabolomics

| Tube Type (Additive) | Primary Mechanism | Key Advantages for LC-MS/MS | Key Disadvantages & Interferences | Recommended Use |

|---|---|---|---|---|

| EDTA (K2/K3) | Chelates Ca²⁺ | Inhibits phospholipases; superior stability for lipids & labile metabolites. Minimal ion suppression. | Can chelate metal ions in MS source; may affect metal-binding analytes. | GOLD STANDARD for broad metabolomics. |

| Lithium Heparin | Activates antithrombin III | No chelator interference in MS. Suitable for trace metal analysis. | Potential for platelet activation, releasing metabolites. Higher phospholipid content. | Acceptable alternative; monitor for platelet-derived artifacts. |

| Serum (Clot Activator) | Promotes clotting | Larger volume yield. Required for some legacy assays. | Clotting releases platelet metabolites (e.g., serotonin). Gel can adsorb lipophilic analytes. | Not recommended for discovery metabolomics; use only if required. |

| Sodium Fluoride/ Oxalate | Glycolysis inhibitor | Stabilizes glucose. | Highly interfering salts; severe ion suppression in MS. | Avoid for global profiling. Use only for dedicated glucose/lactate assays. |

| Citrate | Chelates Ca²⁺ | Used for coagulation studies. | Large dilution factor (3.2-3.8%), diluting metabolites. Interfering citrate peaks in MS. | Not recommended for quantitative metabolite profiling. |

Stabilization & Processing Protocols

Immediate Stabilization Protocol for Labile Metabolites

Objective: To halt enzymatic degradation and chemical oxidation of sensitive metabolite classes (e.g., antioxidants, acyl-carnitines, nucleotides).

Materials: Pre-chilled tubes, ice-water slurry, pre-added stabilization cocktails.

Protocol:

- Draw Blood directly into pre-chilled (4°C) EDTA tubes.

- Immediate Cooling: Place tube in an ice-water slurry (0°C) within 30 seconds of draw.

- Rapid Processing: Centrifuge at 4°C within 30 minutes. For ultra-labile analytes (e.g., glutathione, ATP), consider adding a stabilization cocktail (e.g., 10 µL of 200 mM iodoacetate per mL blood) to the tube immediately after draw.

- Plasma Treatment: For specific pathways, treat plasma immediately after separation:

- For Thiols/Antioxidants: Add 10 µL of 10% (w/v) perchloric acid or 1 M HCl to 100 µL plasma for protein precipitation and stabilization.

- For Choline/ Betaine: None typically needed with rapid freezing.

- Flash-Freezing: Aliquot stabilized plasma into cryovials and submerge in liquid nitrogen for ≥ 2 minutes before transfer to -80°C.

Critical Time-Delay Experiment Protocol

Objective: To quantify metabolite degradation at room temperature and define the maximum allowable processing delay.

Protocol:

- Draw a single blood sample into a pre-chilled EDTA tube.

- Immediately aliquot the whole blood into 5 identical pre-chilled microtubes.

- Time Points: Process each microtube at a different time point after draw: T0 (immediate), T30min, T1h, T2h, T4h. Hold all tubes at room temperature (simulating worst-case scenario) until processing.

- Centrifuge each tube at its designated time point (4°C, 2000 x g, 15 min), aliquot plasma, and flash-freeze.

- Analyze all aliquots in the same LC-MS/MS batch. Plot metabolite abundance vs. time to establish stability thresholds.

Diagrams

Title: Workflow for Fasting and Dynamic Nutritional Challenge Studies

Title: Collection Tube Selection Guide for Nutritional Metabolomics

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Materials for Pre-Analytical Stabilization in Metabolomics

| Item | Function & Rationale | Example/Note |

|---|---|---|

| K2EDTA Blood Collection Tubes | Preferred anticoagulant. Chelates calcium to inhibit coagulation and phospholipase activity, preserving lipidome integrity. | 6 mL or 10 mL tubes (e.g., BD Vacutainer #367525). Use gel-free for metabolomics. |

| Enzyme Inhibitor Cocktails | Stabilize ultra-labile metabolites (e.g., glutathione, nucleotides, acyl-CoAs) by halting enzymatic degradation immediately upon draw. | Commercially available (e.g., PPS, Biopreserver) or lab-made (e.g., iodoacetate for thiols). |

| Pre-Chilled Tube Holders / Ice Slurry | Rapid cooling to 0-4°C slows metabolic activity in whole blood prior to processing, critical for accurate snapshot. | Polystyrene foam racks filled with wet ice/water mixture. |

| Cryogenic Vials (Pre-labeled, Screw-top) | For long-term storage of plasma aliquots at ≤ -80°C. Screw-top with O-ring prevents freeze-drying and sample degradation. | Use internally threaded vials (e.g., Corning, Nunc). Avoid aliquot volumes >500 µL to limit freeze-thaw stress. |

| Liquid Nitrogen Dewar or Pre-Chilled (-80°C) Isopropanol Bath | For rapid, uniform flash-freezing of plasma aliquots. Prevents water crystal formation and preserves metabolite stability. | Essential step prior to transfer to -80°C freezer. |

| Low-Binding Pipette Tips & Microtubes | Minimizes adsorption of hydrophobic or protein-scarce metabolites (e.g., eicosanoids, steroids) to plastic surfaces. | Use polypropylene tubes/ tips with polymer additives (e.g., LoBind from Eppendorf). |

| Internal Standard Mix (for Stabilization QC) | Add at the point of plasma separation to monitor and correct for pre-analytical degradation during processing. | Stable-isotope labeled analogs of labile analytes (e.g., d4-choline, 13C6-glutathione). |

Step-by-Step LC-MS/MS Protocol: Sample Preparation, Chromatography, and Mass Spectrometry Analysis

In LC-MS/MS-based nutritional metabolomics, the accurate profiling of small-molecule metabolites from human plasma is paramount. The initial sample preparation step, deproteinization, is critical for removing interfering proteins, minimizing matrix effects, and ensuring instrument longevity. This application note, framed within a broader thesis on robust LC-MS/MS protocols for nutritional metabolomics, provides a comparative analysis of three core deproteinization techniques: classic Protein Precipitation (PPT), optimized Protein Precipitation (PPT) with novel adsorbents, and Supported Liquid Extraction (SLE). We evaluate their efficiency in metabolite recovery, phospholipid removal, and compatibility with downstream untargeted and targeted analyses.

Table 1: Performance Comparison of Deproteinization Techniques

| Parameter | Classic PPT (Acetonitrile) | Optimized PPT (with Zr-SiO₂) | Supported Liquid Extraction (SLE) |

|---|---|---|---|

| Protein Removal Efficiency | >98% | >99% | >99.5% |

| Phospholipid Removal | ~70% | ~95% | ~85% |

| Average Metabolite Recovery (Polar) | 85-95% | 90-98% | 75-85% |

| Average Metabolite Recovery (Lipophilic) | 60-75% | 85-95% | 90-98% |

| Processed Sample Cleanliness | Moderate | High | High |

| Susceptibility to Matrix Effects (ESI+) | High | Moderate-Low | Low |

| Sample Throughput (96 samples) | ~60 minutes | ~75 minutes | ~90 minutes |

| Organic Solvent Consumption | 300 µL (per 100 µL plasma) | 300 µL (per 100 µL plasma) | 800 µL (per 100 µL plasma) |

| Cost per Sample | Low | Moderate | High |

| Automation Compatibility | Moderate | Moderate | High |

Table 2: Recoveries of Key Metabolite Classes (Mean % ± RSD, n=6)

| Metabolite Class | Example Analyte | Classic PPT | Optimized PPT | SLE |

|---|---|---|---|---|

| Amino Acids | Leucine | 92 ± 4% | 96 ± 3% | 80 ± 6% |

| Carboxylic Acids | Citrate | 88 ± 5% | 94 ± 2% | 78 ± 5% |

| Vitamins | Vitamin B3 (Niacin) | 85 ± 7% | 90 ± 4% | 72 ± 8% |

| Lipids (FFA) | Palmitic Acid | 68 ± 9% | 92 ± 3% | 95 ± 2% |

| Phospholipids | PC(34:2) | 30% Remaining | 5% Remaining | 15% Remaining |

| Steroids | Cortisol | 72 ± 8% | 89 ± 4% | 97 ± 2% |

Detailed Experimental Protocols

Protocol 1: Classic Protein Precipitation (PPT)

- Objective: Rapid, cost-effective protein removal for broad-spectrum metabolomics.

- Materials: Human plasma (100 µL), ice-cold LC-MS grade acetonitrile (300 µL), vortex mixer, microcentrifuge (capable of 13,000 x g), 1.5 mL polypropylene microtubes.

- Procedure:

- Aliquot 100 µL of thawed plasma into a 1.5 mL microtube.

- Add 300 µL of ice-cold acetonitrile.

- Vortex vigorously for 60 seconds.

- Incubate at -20°C for 10 minutes to enhance protein aggregation.

- Centrifuge at 13,000 x g for 10 minutes at 4°C.

- Carefully transfer the clear supernatant (~350 µL) to a clean vial.

- Evaporate to dryness under a gentle stream of nitrogen at 40°C.

- Reconstitute the dried extract in 100 µL of initial LC-MS mobile phase (e.g., 95:5 water:acetonitrile + 0.1% formic acid). Vortex for 60 seconds and centrifuge before LC-MS/MS analysis.

Protocol 2: Optimized PPT with Phospholipid Removal Adsorbent

- Objective: Enhanced phospholipid removal to reduce ion suppression in ESI+ mode.

- Materials: Human plasma (100 µL), ice-cold LC-MS grade acetonitrile (300 µL), zirconia-coated silica (Zr-SiO₂) particles (e.g., 5 mg), vortex mixer, microcentrifuge, 1.5 mL microtubes.

- Procedure:

- Follow steps 1-3 of Protocol 1 (plasma + acetonitrile).

- Add 5 mg of Zr-SiO₂ adsorbent directly to the plasma-acetonitrile mixture.

- Vortex for 120 seconds to ensure complete adsorption of phospholipids.

- Incubate at -20°C for 10 minutes.

- Centrifuge at 13,000 x g for 10 minutes at 4°C.

- Transfer the supernatant, avoiding the pellet of proteins and adsorbent.

- Proceed with evaporation and reconstitution as in Protocol 1 (steps 7-8).

Protocol 3: Supported Liquid Extraction (SLE)

- Objective: High-efficiency, reproducible extraction with superior cleanliness for lipophilic metabolites.

- Materials: Human plasma (100 µL), LC-MS grade water (200 µL), equilibration solution (5% NH₄OH in water, v/v), elution solvent (e.g., methyl tert-butyl ether (MTBE):ethyl acetate, 1:1, v/v), 96-well SLE plate (diatomaceous earth), positive pressure manifold or centrifuge, collection plates, evaporator.

- Procedure:

- Dilute 100 µL plasma with 200 µL of LC-MS grade water and mix gently.

- Condition the SLE plate wells by slowly adding 500 µL of equilibration solution (5% NH₄OH). Allow to soak for 5 minutes, then apply positive pressure/centrifuge to empty.

- Load the diluted plasma sample onto the conditioned SLE bed. Allow it to absorb into the support for 5-10 minutes without airflow.

- Elute metabolites by slowly adding 2 x 400 µL of the organic elution solvent (MTBE:ethyl acetate). Apply gentle pressure/centrifuge after a 2-minute equilibration period for each elution into a clean collection plate.

- Combine the eluates (~800 µL total) and evaporate to complete dryness under nitrogen at 40°C.

- Reconstitute in an appropriate LC-MS compatible solvent (e.g., 80:20 methanol:water) and proceed to analysis.

Visualizations

Plasma Deproteinization Workflow Comparison

Decision Logic for Technique Selection

The Scientist's Toolkit: Essential Research Reagent Solutions

| Item / Reagent Solution | Function & Rationale |

|---|---|

| LC-MS Grade Acetonitrile/Methanol | High-purity, low-UV absorbing solvents for precipitation and reconstitution to prevent background interference in MS detection. |

| Zirconia-Coated Silica (Zr-SiO₂) Particles | Selective adsorbent used in optimized PPT to chelate and remove phospholipids via Lewis acid-base interaction, reducing ion suppression. |

| Supported Liquid Extraction (SLE) Plate | Diatomaceous earth-based support that holds aqueous sample for liquid-liquid extraction with organic solvent, offering reproducibility and automation. |

| Phospholipid Removal SPE Cartridges (e.g., HybridSPE-PPT) | Alternative single-use cartridges combining precipitation and selective filtration for phospholipid removal. |

| Internal Standard Mix (Stable Isotope Labeled) | Added prior to extraction to correct for variability in recovery, evaporation, and matrix effects; critical for quantitative accuracy. |

| MTBE (Methyl tert-butyl ether) | Organic elution solvent for SLE; provides excellent recovery of lipophilic metabolites with low water miscibility. |

| Positive Pressure Manifold (96-well) | Enables simultaneous, controlled processing of multiple SLE or SPE samples, improving throughput and reproducibility over manual methods. |

| Nitrogen Evaporator with Heating Block | For rapid, uniform concentration of organic extracts post-extraction without sample degradation, prior to LC-MS reconstitution. |

Within the framework of a comprehensive thesis on LC-MS/MS protocols for nutritional metabolomics in human plasma, the choice of sample preparation is a critical first step that dictates the breadth and depth of metabolite observation. The fundamental dichotomy lies between targeted extraction, optimized for specific analyte classes, and untargeted extraction, which aims for maximal coverage of the metabolome. The solvent system is the primary lever controlling this selectivity. This application note details contemporary protocols and solvent formulations, balancing extraction efficiency, protein removal, and compatibility with reversed-phase (RP) and hydrophilic interaction liquid chromatography (HILIC) LC-MS/MS analyses.

Core Solvent Systems: Mechanisms and Applications

The efficacy of a solvent system is determined by its ability to precipitate proteins while concurrently solubilizing a wide range of metabolites with varying polarities.

Key Mechanisms:

- Protein Denaturation & Precipitation: Organic solvents (MeOH, ACN) and strong acids (e.g., TCA) disrupt protein hydration shells and charge stability, causing coagulation and removal via centrifugation. This is essential to prevent column fouling and ion suppression.

- Metabolite Solubilization: A biphasic or monophasic mixture determines which metabolite classes partition into the supernatant. Methanol excels at extracting polar and semi-polar metabolites, while acetonitrile offers cleaner backgrounds. Mixtures with water and sometimes chloroform or MTBE enable broader polarity coverage.

Table 1: Quantitative Comparison of Common Solvent Systems for Plasma Metabolomics

| Solvent System (Ratio) | Protein Recovery (%) | Metabolite Class Bias | LC-MS Mode Suitability | Key Advantage | Key Disadvantage |

|---|---|---|---|---|---|

| Methanol (MeOH) 100% | ~95% (Precipitated) | Polar, Semi-polar | RP, HILIC | Excellent for polar central carbon metabolism intermediates; simple protocol. | Poor recovery of very lipophilic metabolites (e.g., triglycerides). |

| Acetonitrile (ACN) 100% | ~98% (Precipitated) | Polar, Semi-polar | RP (optimal) | Superior for RP; less background, sharper peaks. | Can co-precipitate some moderately polar metabolites. |

| MeOH:ACN:H₂O (2:2:1, v/v/v) | ~99% (Precipitated) | Broadest Polar/Semi-polar | RP & HILIC | Combines strengths of MeOH and ACN; minimizes bias; works for lipidomics if biphasic. | Evaporation step required if phase separation occurs. |

| Chloroform:MeOH:H₂O (1:3:1, Bligh & Dyer) | Phase Separates | Lipids (org), Polar (aq) | RP (Lipids) & HILIC (Polar) | True biphasic extraction for simultaneous polar/lipid profiling. | Use of chlorinated solvents; more complex handling. |

| MTBE:MeOH:H₂O (10:3:2.5, Matyash) | Phase Separates | Lipids (org), Polar (aq) | RP (Lipids) & HILIC (Polar) | Less toxic than chloroform; high lipid recovery. | Requires careful phase separation. |

| Trichloroacetic Acid (TCA) 1-5% | ~100% (Precipitated) | Acid-stable Polar (e.g., organic acids) | RP Ion-pairing, HILIC | Very efficient protein removal; good for acidic metabolites. | Harsh acid can degrade labile metabolites (e.g., ATP, some vitamins). |

Detailed Experimental Protocols

Protocol 3.1: Untargeted Extraction Using Modified MeOH:ACN:H₂O

Objective: Maximize coverage of polar to semi-polar metabolites for global profiling. Materials: Human plasma (deproteinized), -80°C storage; LC-MS grade Methanol, Acetonitrile, Water; 1.5 mL microcentrifuge tubes; vacuum concentrator; ultrasonic bath; centrifuge (capable of 14,000 g at 4°C).

- Thawing: Thaw plasma samples on ice.

- Aliquot: Transfer 50 µL of plasma into a pre-chilled 1.5 mL microcentrifuge tube.

- Precipitation/Extraction: Add 200 µL of pre-chilled (-20°C) extraction solvent (Methanol:Acetonitrile:Water, 2:2:1 v/v/v). Vortex vigorously for 30 seconds.

- Incubation: Sonicate in an ice-water bath for 10 minutes.

- Centrifugation: Centrifuge at 14,000 g for 15 minutes at 4°C.

- Collection: Carefully transfer 180 µL of the supernatant (avoiding the protein pellet) to a new, labeled LC-MS vial.

- Drying (Optional): Evaporate to dryness under vacuum and reconstitute in 50 µL of initial LC mobile phase (e.g., 98% H₂O, 2% ACN for HILIC; or 5% ACN, 95% H₂O for RP). Vortex thoroughly. If not drying, dilute 1:1 with aqueous phase.

- Storage: Store at -80°C until LC-MS/MS analysis.

Protocol 3.2: Targeted Lipid Extraction (MTBE Method)

Objective: Selective extraction of lipid classes for targeted lipidomics. Materials: Human plasma; LC-MS grade MTBE, Methanol, Water; 2 mL microcentrifuge tubes; centrifuge.

- Aliquot: Add 50 µL plasma to a 2 mL tube.

- Acidification: Add 150 µL of methanol (containing internal standards). Vortex 10 sec.

- Lipid Extraction: Add 500 µL of Methyl-tert-butyl ether (MTBE). Vortex vigorously for 1 hour at room temperature or shake for 10 min.

- Phase Induction: Add 125 µL of LC-MS grade water to induce phase separation. Vortex for 20 seconds.

- Centrifugation: Centrifuge at 14,000 g for 10 minutes at 20°C.

- Collection: Two clear phases form. The upper (organic) phase contains lipids. Collect ~400 µL of the upper phase into a clean vial.

- Drying: Evaporate under a gentle stream of nitrogen or vacuum.

- Reconstitution: Reconstitute in 100 µL of appropriate solvent (e.g., 9:1 IPA:MeOH or MeOH:CHCl₃). Vortex and sonicate to dissolve.

- Storage: Store at -80°C until analysis.

Visualizations

Title: Solvent System Selection Logic Flow

Title: Generic Plasma Metabolite Extraction Workflow

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function & Rationale |

|---|---|

| LC-MS Grade Solvents (MeOH, ACN, Water, IPA) | Ultra-pure to minimize background chemical noise, ion suppression, and column contamination. Essential for sensitive detection. |

| Methyl-tert-butyl ether (MTBE) | A less toxic, less dense alternative to chloroform for biphasic lipid extractions. Forms a distinct upper organic phase. |

| Internal Standard Mixtures | A cocktail of isotopically labeled analogs (e.g., ¹³C, ²H) of various metabolite classes. Spiked-in pre-extraction to correct for losses during preparation and matrix effects during MS analysis. |

| Protein LoBind Tubes (1.5-2 mL) | Minimize non-specific adsorption of metabolites (especially lipids and peptides) to tube walls, improving recovery and reproducibility. |

| Vacuum Concentrator (SpeedVac) | For gentle, uniform removal of extraction solvents without excessive heat, prior to reconstitution in LC-compatible buffer. |

| C18 & HybridSPE-Precipitation Plates | For automated, high-throughput protein precipitation. HybridSPE uses zirconia-coated silica to selectively remove phospholipids—a major source of ion suppression. |

| Biological pH Buffers (e.g., Ammonium Acetate, Formate) | Used in extraction or reconstitution to stabilize pH-sensitive metabolites and enhance ionization efficiency in ESI-MS. |

Within the framework of a thesis on LC-MS/MS protocols for human plasma nutritional metabolomics, column chemistry selection is a pivotal initial step. Human plasma contains a highly complex mixture of metabolites spanning a wide polarity range, from polar amino acids and sugars to non-polar lipids and fat-soluble vitamins. The choice between Hydrophilic Interaction Liquid Chromatography (HILIC) and Reversed-Phase (RP) chromatography dictates metabolite coverage, sensitivity, and overall analytical success.

Principle and Application Comparison

HILIC employs a polar stationary phase (e.g., bare silica, amino, amide) with a hydrophobic mobile phase (high organic, e.g., acetonitrile). Analytes elute in order of increasing polarity. It is ideal for retaining and separating small, polar, and ionic compounds that elute too quickly or not at all in RP.

Reversed-Phase utilizes a non-polar stationary phase (e.g., C18, C8) with a polar mobile phase (water/organic gradient). Analytes elute in order of decreasing polarity. It is the gold standard for medium to non-polar compounds.

Table 1: Direct Comparison of HILIC vs. Reversed-Phase for Metabolomics

| Parameter | HILIC | Reversed-Phase (C18) |

|---|---|---|

| Stationary Phase | Polar (Silica, Amide, Diol) | Non-polar (C18, C8, Phenyl) |

| Mobile Phase Start | High Organic (≥70% ACN) | High Aqueous (≥90% Water) |

| Elution Order | Polar Last | Polar First |

| Optimal for | Polar metabolites (Sugars, Organic acids, Nucleotides, Polar lipids) | Mid-to-Non-polar metabolites (Lipids, Steroids, Fat-soluble vitamins, Flavonoids) |

| Plasma Sample Prep | Protein precipitation with ACN recommended; supernatant compatible with injection. | Protein precipitation with MeOH or ACN; may require evaporation/reconstitution. |

| Gradient Time (Typical) | 15-25 min | 15-30 min |

| MS Compatibility | High initial organic can enhance ionization. | May require post-column addition for optimal ionization of early eluters. |

| Key Challenge | Long column equilibration, sensitivity to buffer conc. | Poor retention of very polar metabolites. |

Detailed Experimental Protocols

Protocol 3.1: Two-Platform Metabolomics Screening for Human Plasma

Objective: To comprehensively cover a broad metabolite spectrum from a single plasma extract using complementary HILIC and RP separations coupled to high-resolution MS/MS.

Materials & Reagents:

- Human plasma samples (post-prandial, fasted state).

- Cold HPLC-grade methanol, acetonitrile (ACN), and water.

- Ammonium acetate, formic acid (MS grade).

- Internal Standard Mix: Stable isotope-labeled amino acids, fatty acids, sugars (e.g., Cambridge Isotope Laboratories).

- HILIC Column: e.g., Acquity UPLC BEH Amide (2.1 x 100 mm, 1.7 µm).

- RP Column: e.g., Acquity UPLC HSS T3 (2.1 x 100 mm, 1.8 µm).

Procedure:

- Sample Preparation:

- Thaw plasma on ice. Vortex briefly.

- Aliquot 50 µL plasma into a microcentrifuge tube.

- Add 150 µL of cold MeOH:ACN (1:1, v/v) containing the internal standard mix.

- Vortex vigorously for 1 min. Incubate at -20°C for 1 hour to precipitate proteins.

- Centrifuge at 17,000 x g for 15 min at 4°C.

- Transfer 150 µL of supernatant to a fresh LC vial for RP analysis.

- For HILIC analysis, take a separate 50 µL aliquot of plasma, precipitate with 200 µL of cold ACN, centrifuge, and use the supernatant directly.

LC-MS/MS Conditions (RP):

- Column: HSS T3, 45°C.

- Mobile Phase: A: 0.1% Formic acid in water; B: 0.1% Formic acid in ACN.

- Gradient: 1% B to 99% B over 18 min, hold 2 min, re-equilibrate for 5 min.

- Flow Rate: 0.4 mL/min. Injection: 2 µL.

- MS: ESI positive/negative switching, data-dependent acquisition (DDA).

LC-MS/MS Conditions (HILIC):

- Column: BEH Amide, 45°C.

- Mobile Phase: A: 10mM Ammonium acetate in 95% ACN, pH 9.0; B: 10mM Ammonium acetate in water, pH 9.0.

- Gradient: 95% A to 60% A over 16 min, hold 2 min, re-equilibrate at 95% A for 7 min.

- Flow Rate: 0.5 mL/min. Injection: 3 µL.

- MS: ESI positive/negative switching, DDA.

Protocol 3.2: Targeted Bile Acid Analysis via HILIC

Objective: Separate and quantify isomeric conjugated bile acids (polar) in human plasma.

Procedure:

- Sample Prep: As per HILIC prep above (ACN precipitation).

- LC Conditions:

- Column: ZIC-pHILIC (150 x 2.1 mm, 5 µm).

- Mobile Phase: A: 20mM Ammonium carbonate in water; B: ACN.

- Gradient: 80% B to 50% B over 12 min.

- Flow: 0.2 mL/min. Temp: 40°C. Inj: 5 µL.

- MS/MS: Negative ESI, Multiple Reaction Monitoring (MRM).

Protocol 3.3: Comprehensive Lipidomics via Reversed-Phase

Objective: Profile non-polar to mid-polar lipid classes (TAG, DAG, PL, CE) in a single run. Procedure:

- Sample Prep: Use RP preparation (MeOH:ACN).

- LC Conditions:

- Column: CORTECS C18+ (2.1 x 100 mm, 1.6 µm).

- Mobile Phase: A: 10mM Ammonium formate in 60% ACN/Water; B: 10mM Ammonium formate in 90% IPA/ACN.

- Gradient: 40% B to 100% B over 20 min.

- Flow: 0.4 mL/min. Temp: 55°C.

- MS/MS: Positive/Negative ESI with polarity switching.

Visualizations

Diagram Title: LC Column Selection Workflow for Metabolites

Diagram Title: Dual-Platform Metabolomics Analysis Protocol

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for LC-MS/MS Metabolomics of Plasma

| Item | Function & Rationale |

|---|---|

| HILIC Column (e.g., BEH Amide) | Provides strong retention of polar metabolites via hydrogen bonding and dipole-dipole interactions. Critical for analyzing sugars, organic acids, and polar lipids. |

| RP Column (e.g., C18 with aqueous retention) | Standard workhorse for lipidomics and mid-polar metabolites. Modern phases like T3 or C18+ offer better retention for some polar compounds. |

| Stable Isotope Internal Standards (SIL-IS) | Corrects for matrix effects and extraction variability. Essential for accurate quantification. Include a mix spanning polar/non-polar classes. |

| MS-Grade Ammonium Salts (Acetate/Formate) | Provides volatile buffering for mobile phases. Ammonium acetate (pH~9) is common for HILIC; formate is common for RP in positive ESI. |

| Cold Methanol & Acetonitrile (HPLC Grade) | Solvents for protein precipitation. ACN is preferred for HILIC-friendly extracts. MeOH is more efficient for broad precipitation. |

| Solid Phase Extraction (SPE) Plates (C18, Mixed-Mode) | For advanced sample clean-up to remove phospholipids and salts, reducing ion suppression and column contamination. |

Within the broader thesis on developing robust LC-MS/MS protocols for nutritional metabolomics in human plasma research, mobile phase optimization is a critical pillar. The complexity of the plasma metabolome—spanning polar vitamins, hydrophobic lipids, and ionic organic acids—demands meticulous attention to chromatographic conditions. Poor peak shape, manifested as fronting, tailing, or broadening, directly compromises sensitivity, reproducibility, and accurate quantification, ultimately jeopardizing the integrity of nutritional intervention studies. This application note details systematic strategies for optimizing aqueous and organic mobile phases through buffer selection, additive use, and gradient profile design to achieve sharp, symmetric peaks for diverse metabolite classes.

Core Principles & Recent Findings

Live search data confirms that current best practices emphasize volatile buffers compatible with MS detection. Key trends include:

- Ammonium Formate/Acetate Dominance: These remain the gold-standard buffers (typically 2-10 mM, pH 3.5-5.0) for positive- and negative-mode electrospray ionization (ESI), respectively.

- Additives for Challenging Analytes: For acidic metabolites (e.g., short-chain fatty acids, bile acids), 0.1% formic acid is standard for positive mode, while low concentrations (0.1-1 mM) of hydrophilic ion-pairing agents like dimethylhexylamine (DMHA) can improve peak shape for polar anions without severe MS suppression. Conversely, for basic compounds, amines like diethylamine (DEA, 0.01-0.1%) can mitigate silanol interactions.

- Gradient Steepness and Re-equilibration: A linear gradient with a slope of 1-5% organic modifier per minute is often optimal for complex metabolomic samples. Adequate column re-equilibration (>5 column volumes) between runs is non-negotiable for retention time stability.

- Column Chemistry Synergy: Optimization is inseparable from stationary phase choice. For instance, charged surface hybrid (CSH) columns benefit from specific additive adjustments.

Key Research Reagent Solutions

The following table lists essential materials for mobile phase optimization in nutritional metabolomics LC-MS/MS.

Table 1: Essential Research Reagents for Mobile Phase Optimization

| Reagent/ Material | Function in Mobile Phase Optimization |

|---|---|

| Ammonium Formate (LC-MS Grade) | Volatile buffer salt for pH control in positive and negative ESI; reduces adduct formation. |

| Ammonium Acetate (LC-MS Grade) | Volatile buffer for pH control; often preferred in negative ESI for some analyte classes. |

| Formic Acid (LC-MS Grade, ≥99%) | Common acidic additive (0.05-0.1%) to promote protonation in positive ESI and improve peak shape for acids. |

| Acetic Acid (LC-MS Grade) | Milder acidic alternative to formic acid; sometimes reduces in-source fragmentation. |

| Ammonium Hydroxide (LC-MS Grade) | Basic additive for negative ESI to promote deprotonation; used sparingly to adjust pH. |

| Dimethylhexylamine (DMHA) | Hydrophilic ion-pairing agent at low concentration (e.g., 1 mM) to improve peak shape of polar anions (TCA cycle intermediates). |

| Diethylamine (DEA) | Basic additive (0.01-0.1%) to block active silanol sites and reduce tailing of basic metabolites. |

| Water (LC-MS Grade) | Aqueous mobile phase base; must be ultra-pure, organic-free. |

| Acetonitrile (LC-MS Grade) | Primary organic modifier; provides low viscosity and background, high elution strength. |

| Methanol (LC-MS Grade) | Alternative organic modifier; different selectivity for some lipid classes; higher viscosity. |

Experimental Protocols

Protocol 1: Systematic Screening of Buffer pH and Additives

Objective: Identify optimal pH and additive for peak symmetry of target metabolite panels.

- Prepare Stock Buffers: Prepare 100 mM ammonium formate (for pH 3.0-5.0) and ammonium acetate (for pH 5.0-8.0) solutions in LC-MS grade water. Adjust pH with formic acid or ammonium hydroxide as needed.

- Prepare Mobile Phases: Create a matrix of mobile phase A solutions: 5 mM buffer at pH 3.0, 4.0, 5.0, 6.0, 7.0, and 8.0, each with and without 0.1% formic acid (for positive mode) or 0.1% ammonium hydroxide (for negative mode). Mobile phase B is acetonitrile with same additive as paired mobile phase A.

- Chromatography: Inject a standardized plasma metabolite extract containing representative acids, bases, and neutrals. Use a shallow, generic gradient (e.g., 5-95% B in 10 min) on a C18 column.

- Analysis: Calculate asymmetry factor (As) at 10% peak height for each analyte. Select condition yielding As closest to 1.0 for the broadest set of critical analytes.

Protocol 2: Optimizing Gradient Elution Profile

Objective: Develop a gradient that maximizes peak capacity and resolution for a wide metabolomic scope.

- Initial Scouting Run: Using the best buffer/additive from Protocol 1, perform a fast gradient from 1% to 99% B in 15 minutes.

- Analyze Distribution: Plot detected peaks by their retention time and logP (if known). Identify regions of co-elution and excessive void time.

- Design Multi-Segment Gradient: Introduce a shallow initial segment (e.g., 1-10% B over 3 min) to resolve polar metabolites. Steepen the gradient for mid-hydrophobicity compounds (10-70% B over 8 min), and use a final sharp rise for lipids (70-99% B in 2 min).

- Validate and Adjust: Inject the sample with the new gradient. Adjust segment slopes to evenly distribute peaks. Ensure a 5-minute re-equilibration at initial conditions.

Protocol 3: Evaluating Ion-Pairing Additives for Polar Anions

Objective: Improve peak shape and retention of TCA cycle intermediates and other carboxylic acids.

- Prepare Additive Solutions: Prepare mobile phase A (water) with: a) 0.1% formic acid (control), b) 10 mM ammonium acetate pH 6.5, c) 10 mM ammonium acetate pH 6.5 + 1 mM DMHA.

- Chromatography: Use a HILIC or reversed-phase column. Inject a standard mix of polar acids (e.g., citrate, succinate, malate, α-ketoglutarate). Use an isocratic or shallow gradient method.

- Assessment: Compare peak shape, retention factor (k), and signal intensity. Note: DMHA requires extensive column washing (≥30 column volumes) to remove.

Data Presentation

Table 2: Effect of Buffer pH and Additive on Peak Asymmetry (As) of Representative Metabolites (C18 Column, Positive ESI)

| Metabolite Class | Example | 5 mM NH₄Frm, pH 3.0 | 5 mM NH₄Frm, pH 3.0 + 0.1% FA | 5 mM NH₄Frm, pH 5.0 | 5 mM NH₄Frm, pH 5.0 + 0.1% FA |

|---|---|---|---|---|---|

| Basic | Choline | 1.85 (Tailing) | 1.15 | 2.10 | 1.25 |

| Acidic | Pantothenate | 0.92 | 0.95 | 1.05 | 1.08 |

| Neutral | Glucose | 1.10 | 1.12 | 1.08 | 1.10 |

| Amphoteric | Tryptophan | 1.02 | 1.01 | 1.20 | 1.18 |

Table 3: Impact of Gradient Slope on Peak Parameters in Plasma Metabolomics

| Gradient Slope (%B/min) | Average Peak Width (min) | Average Asymmetry Factor | Number of Peaks Detected (m/z 50-1000) |

|---|---|---|---|

| 2 | 0.18 | 1.05 | 450 |

| 5 | 0.22 | 1.08 | 425 |

| 10 | 0.35 | 1.15 | 380 |

Visualized Workflows & Relationships

Title: Mobile Phase Optimization Decision Workflow

Title: Gradient Steepness Effect on Chromatographic Peaks

Within the framework of LC-MS/MS protocols for nutritional metabolomics in human plasma research, the selection of detection mode is paramount. This application note details two core MS/MS strategies: Multiple Reaction Monitoring (MRM) for targeted quantification and Data-Dependent Acquisition (DDA) for untargeted discovery. The former delivers high sensitivity and precision for known metabolites, while the latter enables hypothesis-free profiling of the plasma metabolome to identify novel nutritional biomarkers.

Core Detection Modes: Principles and Applications

Targeted Quantification via Multiple Reaction Monitoring (MRM)

MRM on triple quadrupole mass spectrometers is the gold standard for quantifying predefined metabolites with high accuracy, precision, and sensitivity. It is ideal for validating hypotheses, conducting large cohort studies, and performing absolute quantification.

Principle: The first quadrupole (Q1) filters for the precursor ion of a specific metabolite. The second quadrupole (q2, collision cell) fragments the ion. The third quadrupole (Q3) filters for a unique, abundant product ion. This two-stage filtering drastically reduces chemical noise.

Key Applications in Nutritional Metabolomics:

- Quantification of vitamin metabolites (e.g., A, D, B9, B12).

- Measurement of essential fatty acids and their oxidation products.

- Monitoring of amino acid levels post-intervention.

- Validation of candidate biomarkers from discovery-phase studies.

Untargeted Discovery via Data-Dependent Acquisition (DDA)

DDA, typically on quadrupole-time-of-flight (Q-TOF) or Orbitrap instruments, is used for comprehensive profiling of the metabolome without prior target lists. It is essential for discovery-phase research to identify differentially expressed metabolites in response to dietary interventions.

Principle: The instrument performs an initial MS1 scan to record all ions within a mass range. In real-time, it selects the most intense (or other predefined criteria) precursor ions from the MS1 scan for subsequent MS2 fragmentation. This cycle repeats, building a library of fragmentation spectra for compound identification.

Key Applications in Nutritional Metabolomics:

- Discovery of novel dietary biomarkers.

- Profiling of unknown metabolic shifts.

- Generating hypotheses on metabolic pathways affected by nutrition.

- Compound identification in complex plasma samples.

Table 1: Comparative Overview of MRM and DDA Modes

| Feature | MRM (Targeted Quantification) | DDA (Untargeted Discovery) |

|---|---|---|

| Primary Goal | High-quality quantification of known analytes. | Identification of unknown or unexpected compounds. |

| Instrument Type | Triple Quadrupole (QqQ). | Q-TOF, Quadrupole-Orbitrap. |

| Throughput | High (10s-100s of targets per method). | Moderate (limited by cycle time). |

| Sensitivity | Excellent (fg-pg on-column). | Good (pg-ng on-column). |

| Dynamic Range | 4-6 orders of magnitude. | 3-4 orders of magnitude. |

| Quantitative Rigor | Excellent (uses internal standards). | Semi-quantitative (relative comparison). |

| Identification Power | Low (confirmation only). | High (MS/MS spectra for library matching). |

| Optimal Use Case | Validating & quantifying predefined panels (e.g., vitamins, bile acids). | Discovery of novel biomarkers, pathway analysis. |

Detailed Experimental Protocols

Protocol 1: MRM Quantification of Fat-Soluble Vitamins in Human Plasma

Objective: To absolutely quantify vitamins A (retinol), D3 (25-hydroxy), E (α-tocopherol), and K1 (phylloquinone) in human plasma.

I. Sample Preparation (Solid-Phase Extraction)

- Thaw plasma samples on ice. Aliquot 200 µL into a microcentrifuge tube.

- Add 20 µL of a stable isotope-labeled internal standard (IS) mixture (e.g., d6-retinol, d6-25-OH-D3, d6-α-tocopherol, d4-K1).

- Precipitate proteins by adding 400 µL of cold methanol containing 0.1% BHT (antioxidant). Vortex for 1 min, then incubate at -20°C for 15 min.

- Centrifuge at 14,000 x g for 10 min at 4°C.

- Load the supernatant onto a pre-conditioned (1 mL methanol, 1 mL water) C18 SPE cartridge.

- Wash with 1 mL of 30% methanol in water. Elute analytes with 500 µL of dichloromethane:methanol (80:20, v/v).

- Evaporate the eluent to dryness under a gentle nitrogen stream at 30°C.

- Reconstitute the dry residue in 100 µL of methanol:dichloromethane (90:10, v/v) for LC-MS/MS analysis.

II. LC-MS/MS Analysis (MRM Mode)

- LC System: Reversed-phase C18 column (2.1 x 100 mm, 1.8 µm). Column temperature: 45°C.

- Mobile Phase: A: 0.1% Formic acid in water. B: 0.1% Formic acid in methanol.

- Gradient: 80% B to 100% B over 8 min, hold at 100% B for 4 min, re-equilibrate for 4 min. Flow rate: 0.3 mL/min.

- MS System: Triple quadrupole MS with positive/negative ion switching ESI source.

- Ion Source Parameters: Capillary voltage: 3.0 kV (pos), 2.7 kV (neg); Source temperature: 150°C; Desolvation temperature: 400°C.

- MRM Transitions: Program specific precursor→product ion transitions, optimal collision energies, and dwell times (e.g., for Vitamin A: m/z 269.2 → 93.1, CE 25 eV).

III. Data Processing

- Integrate peak areas for each analyte and its corresponding IS.

- Calculate the analyte/IS peak area ratio.

- Quantify using a 6-point calibration curve (prepared in surrogate matrix) with linear regression (1/x weighting).

Protocol 2: DDA for Discovery of Nutritional Biomarkers in Human Plasma

Objective: To perform untargeted profiling of polar metabolites in human plasma to discover compounds differentiating two dietary intervention groups.

I. Sample Preparation (Protein Precipitation)

- Thaw plasma on ice. Aliquot 50 µL into a microcentrifuge tube.

- Add 200 µL of cold acetonitrile:methanol (1:1, v/v) containing a pooled QC IS (a mix of compounds not expected in samples).

- Vortex vigorously for 1 min, then incubate at -20°C for 1 hour.

- Centrifuge at 18,000 x g for 15 min at 4°C.

- Transfer 150 µL of the supernatant to a clean LC-MS vial with insert. Evaporate to complete dryness in a centrifugal vacuum concentrator.

- Reconstitute in 50 µL of 5% acetonitrile in water for hydrophilic interaction chromatography (HILIC) analysis.

II. LC-MS/MS Analysis (DDA Mode)

- LC System: HILIC column (e.g., Amide, 2.1 x 150 mm, 1.7 µm). Column temperature: 40°C.

- Mobile Phase: A: 10 mM ammonium formate, pH 3.0 in water. B: Acetonitrile.

- Gradient: 85% B to 40% B over 15 min, hold for 3 min, re-equilibrate. Flow: 0.25 mL/min.

- MS System: Quadrupole-Orbitrap MS in both positive and negative ESI modes.

- Data Acquisition Parameters:

- MS1 Scan: Resolution: 70,000; Scan range: m/z 70-1050; AGC target: 1e6.

- DDA Criteria: Top 10 most intense ions per cycle from MS1 scan.

- MS2 Scan: Resolution: 17,500; Isolation window: 1.2 m/z; HCD collision energy: stepped (20, 40, 60 eV); Dynamic exclusion: 15 s.

III. Data Processing & Identification

- Process raw files using untargeted software (e.g., MS-DIAL, Compound Discoverer).

- Perform peak picking, alignment, and deconvolution.

- Annotate features by matching MS1 (accurate mass) and MS2 spectra against public (e.g., HMDB, MassBank) and commercial libraries (mass error < 5 ppm, MS2 similarity score > 0.7).

- Perform multivariate statistical analysis (PCA, PLS-DA) to find significant features.

- Confirm identities of key biomarkers using authentic chemical standards.

Visualized Workflows and Relationships

Diagram 1: LC-MS/MS Workflow for Nutritional Metabolomics

Diagram 2: MRM Principle on a Triple Quadrupole MS

Diagram 3: Data-Dependent Acquisition (DDA) Cycle

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Nutritional Metabolomics LC-MS/MS

| Item | Function in Protocol | Example/Criteria |

|---|---|---|

| Stable Isotope-Labeled Internal Standards (SIL-IS) | Correct for matrix effects & losses during sample prep; essential for accurate MRM quantification. | d6-retinol, 13C6-glucose, 15N-amino acid mixes. |

| LC-MS Grade Solvents | Minimize background noise and ion suppression; ensure reproducibility. | Methanol, Acetonitrile, Water (Optima LC/MS grade). |

| SPE Cartridges | Selective clean-up and concentration of analytes from complex plasma matrix. | C18 (for lipids, vitamins), Mixed-Mode (for polar/ionic metabolites). |

| Quality Control (QC) Pool | Monitor system stability and performance in untargeted runs. | Pooled aliquot of all study samples. |

| Metabolite Libraries | Identify unknown features from DDA experiments by MS2 spectral matching. | NIST MS/MS, MassBank, HMDB, commercial IROA libraries. |

| Authentic Chemical Standards | Confirm identity and create calibration curves for quantification. | >95% purity, certified reference materials when available. |

| Protein Precipitation Solvents | Rapid deproteination for global metabolite extraction in DDA. | Cold ACN, MeOH, or mixtures (e.g., 2:2:1 ACN:MeOH:Water). |

| HILIC & Reversed-Phase Columns | Separate the diverse range of metabolites present in plasma. | BEH Amide (HILIC), C18 (RP) with sub-2µm particles for high resolution. |

1. Introduction Within the framework of a thesis on robust LC-MS/MS protocols for nutritional metabolomics in human plasma, the precision and accuracy of quantification are paramount. Biological matrices like plasma introduce significant analytical challenges, including ion suppression/enhancement, variable extraction efficiency, and analyte degradation. The stable isotope-labeled internal standard (SIL-IS) strategy is the cornerstone for overcoming these hurdles. By using an analog identical in chemical structure and chromatographic behavior but distinguishable by mass, the SIL-IS corrects for losses and matrix effects, ensuring reliable absolute quantification of nutritional biomarkers (e.g., vitamins, amino acids, fatty acids, plant metabolites).

2. Core Principles & Quantitative Advantages A SIL-IS is a molecule where atoms (e.g., ^1H, ^12C, ^14N) are replaced by their stable heavy isotopes (e.g., ^2H (D), ^13C, ^15N). It is added to the sample at the earliest possible step, typically before protein precipitation.

Table 1: Quantitative Impact of SIL-IS vs. Other Calibration Methods in Plasma Metabolomics

| Calibration Method | Matrix Effect Correction | Extraction Recovery Correction | Typical Accuracy (% of nominal) | Typical Precision (% RSD) | Key Limitation |

|---|---|---|---|---|---|

| External Standard | No | No | 70-130% | >15% | Highly susceptible to matrix variability. |

| Analog Internal Std | Partial | Partial | 80-120% | 10-15% | Differential extraction/chromatography. |

| Stable Isotope-Labeled IS | Yes | Yes | 95-105% | <10% | Cost; potential for isotopic cross-talk. |

3. Application Notes: Selection and Use of SIL-IS

- Selection Criteria: The ideal SIL-IS contains a minimum of 3-4 heavy atoms to minimize interference from the natural isotopic abundance of the analyte. ^13C- or ^15N-labeled analogs are preferred over deuterated ones, as deuterium can exhibit slight chromatographic isotopic fractionation (retention time shift).

- Optimal Addition Point: The SIL-IS should be spiked into the plasma sample immediately upon thawing, prior to any protein precipitation or extraction step. This ensures it co-experiences all sample preparation variances.

- Concentration: The SIL-IS concentration should be within the linear range of the calibration curve, often near the middle of the expected biological concentration.

- Calibration Curve: Calibration standards are prepared in a surrogate matrix (e.g., stripped plasma, buffer) containing a constant concentration of the SIL-IS. The response ratio (Analyte peak area / SIL-IS peak area) is plotted against the nominal analyte concentration.

4. Detailed Protocol: LC-MS/MS Quantification of Vitamin D3 [25(OH)D3] in Human Plasma Using a SIL-IS

Objective: To accurately quantify 25-hydroxyvitamin D3 in 100 µL of human plasma using d6-25(OH)D3 as the SIL-IS.

4.1. Research Reagent Solutions & Essential Materials Table 2: Scientist's Toolkit for SIL-IS-Based Plasma Metabolomics

| Item | Function | Example (for 25(OH)D3) |

|---|---|---|

| Stable Isotope-Labeled IS | Corrects for all procedural losses & matrix effects. | d6-25(OH)D3 (26,26,26,27,27,27-D6) |

| Surrogate Matrix | For preparation of calibration standards. | Charcoal-stripped human plasma |

| Protein Precipitation Solvent | Denatures and removes proteins. | Cold Methanol with 0.1% Formic Acid |

| Liquid-Liquid Extraction Solvent | Isolates analytes from aqueous matrix. | Hexane or Methyl-tert-butyl ether (MTBE) |

| LC-MS Grade Solvents | Minimizes background noise in chromatography. | Methanol, Acetonitrile, Water (all LC-MS grade) |