Nanotechnology for Enhanced Nutrient Delivery: Innovations in Drug Formulations and Agricultural Solutions

This article explores the transformative role of nanotechnology in creating advanced nutrient and drug delivery systems.

Nanotechnology for Enhanced Nutrient Delivery: Innovations in Drug Formulations and Agricultural Solutions

Abstract

This article explores the transformative role of nanotechnology in creating advanced nutrient and drug delivery systems. It examines foundational concepts, including the use of nanocarriers like liposomes, polymeric nanoparticles, and dendrimers to improve the solubility, stability, and bioavailability of active compounds. For researchers and drug development professionals, the content covers methodological advances in targeted and controlled-release formulations, addresses key challenges in scalability and safety, and provides a comparative analysis of therapeutic efficacy and market viability across biomedical and agricultural applications. The review synthesizes current trends and future directions to guide innovation in this rapidly evolving field.

The Foundation of Nano-Delivery: Principles, Materials, and Mechanisms of Action

A significant proportion of active pharmaceutical ingredients (APIs) and bioactive nutrients face critical delivery challenges that severely limit their therapeutic efficacy. It is estimated that 40% of existing drugs and 70-90% of drug candidates in development exhibit poor water solubility, leading to inadequate dissolution profiles, insufficient systemic absorption, and ultimately, low bioavailability [1] [2]. These challenges are equally prevalent in the nutraceutical sector, where valuable compounds like vitamins, polyphenols, carotenoids, and phytosterols demonstrate exceptionally low absorption rates due to chemical instability in the gastrointestinal environment, rapid degradation, and poor membrane permeability [3] [4].

Nanotechnology has emerged as a transformative approach to overcoming these biological barriers through the design and application of nanoscale delivery systems. By engineering materials at the 1-100 nanometer scale, scientists can access unique physicochemical properties that enable precise control over drug/nutrient release kinetics, enhance solubility parameters, and provide protective encapsulation against degradative environments [5] [6]. These advanced delivery platforms represent a paradigm shift in formulation science, offering targeted transport mechanisms that significantly improve the therapeutic index of bioactive compounds.

Nanocarrier Platforms: Mechanisms and Applications

Classification and Properties of Nanodelivery Systems

Various nanocarrier architectures have been developed to address specific challenges associated with poor solubility, instability, and low bioavailability. Each system offers distinct advantages based on its structural composition, encapsulation efficiency, and release mechanisms.

Table 1: Characterization of Major Nanocarrier Platforms for Enhanced Bioavailability

| Nanocarrier Type | Key Composition | Mechanism of Action | Applications | Key Advantages |

|---|---|---|---|---|

| Lipid Nanoparticles | Phospholipids, triglycerides, surfactants [4] | Enhanced solubilization in GI tract, lymphatic absorption [2] | BCS Class II & IV drugs, nutraceuticals [2] | Biocompatibility, improved permeability, controlled release [4] |

| Polymeric Nanoparticles | PLGA, chitosan, gelatin, polyesters [7] [8] | Protection from degradation, modulated release kinetics [8] | Cancer therapy, sustained release formulations [7] [8] | Tunable properties, surface functionalization capability [5] |

| Nanoemulsions | Oil, water, emulsifiers (surfactants) [4] [9] | Increased surface area for absorption, enhanced solubility [9] | Lipophilic bioactive compounds, antioxidants [9] | Ease of preparation, thermodynamic stability [4] |

| Liposomes | Phospholipid bilayers enclosing aqueous core [7] [4] | Encapsulation of both hydrophilic and hydrophobic compounds [7] | Vitamin delivery, anticancer agents [3] [7] | Dual loading capacity, biocompatible composition [7] |

| Inorganic Nanoparticles | Mesoporous silica, gold, iron oxide [7] [8] | High surface area for adsorption, stimulus-responsive release [7] | Targeted drug delivery, theranostics [8] | Precise size control, multifunctionality [5] |

| Nanobubbles | Gas core with polymeric/surfactant shells [10] | Ultrasound-triggered cavitation and release [10] | Targeted cancer therapy, nutrient delivery [10] | External triggering capability, enhanced tissue penetration [10] |

Quantitative Efficacy of Nanodelivery Systems

The enhancement of bioavailability through nanotechnology has been quantitatively demonstrated across multiple studies and delivery systems. The following table summarizes key performance metrics reported in recent research.

Table 2: Efficacy Metrics of Selected Nanodelivery Systems

| Delivery System | Bioactive Compound | Key Efficacy Metrics | Reference |

|---|---|---|---|

| Silk Fibroin Particles | Curcumin, 5-FU | Encapsulation efficiency: 37% (CUR), 82% (5-FU); Sustained release over 72 hours | [7] |

| Clarithromycin-loaded BSA Nanoparticles | Clarithromycin | Controlled release >50% in reductive media; Significant anticancer activity against A549 cells | [7] |

| Chitosan-coated Lipid Microvesicles | Diclofenac | Superior anti-inflammatory effects and greater enhancement of antioxidant enzyme activity vs. free drug | [7] |

| Hyaluronic Acid-based Nanoparticles | Rutin | Significant reduction in cell death and inflammation (p < 0.001); Lower inflammatory markers | [7] |

| Mesoporous Silica Nanoparticles | Chlorambucil | Significantly higher cytotoxicity and greater selectivity for cancer cells vs. free drug | [7] |

| Poly-N-vinylpyrrolidone Nanoparticles | Indomethacin | Controlled prolonged release in vitro and in vivo; Improved pharmacokinetics; Reduced accumulation in liver/kidneys | [8] |

Experimental Protocols

Protocol 1: Preparation and Characterization of Solid Lipid Nanoparticles (SLNs)

Objective: To fabricate and characterize solid lipid nanoparticles for enhanced delivery of poorly water-soluble bioactive compounds.

Materials:

- Primary lipid component (e.g., glyceryl palmitostearate, Compritol 888 ATO)

- Surfactant system (e.g., Poloxamer 188, Tween 80)

- Active pharmaceutical ingredient/nutraceutical (e.g., fat-soluble vitamin, antifungal agent)

- Distilled water (aqueous phase)

Methodology:

Hot Homogenization Technique:

- Heat lipid phase containing the active compound to approximately 5-10°C above its melting point.

- Simultaneously, heat the aqueous surfactant solution to the same temperature.

- Add the aqueous phase to the lipid phase under high-speed stirring (500-1000 rpm) to form a pre-emulsion.

- Subject the pre-emulsion to high-pressure homogenization at 500-1500 bar for 3-5 cycles while maintaining temperature.

- Allow the resulting nanoemulsion to cool to room temperature under mild stirring, facilitating lipid solidification and SLN formation.

Characterization Parameters:

- Particle Size and Polydispersity Index: Determine using dynamic light scattering (DLS). Optimal size range: 50-200 nm with PDI <0.3 [4].

- Zeta Potential: Measure using electrophoretic light scattering. Values >|25| mV indicate good physical stability [5].

- Encapsulation Efficiency: Separate unencapsulated drug by ultracentrifugation or dialysis. Quantify drug content in supernatant using HPLC/UV spectroscopy. Calculate EE% = (Total drug - Free drug)/Total drug × 100 [7].

- In Vitro Release Profile: Utilize Franz diffusion cells or dialysis membrane method in appropriate release medium (e.g., PBS pH 7.4). Sample at predetermined intervals and analyze drug content [8].

Critical Quality Attributes:

- Monitor crystallinity of lipid matrix using differential scanning calorimetry (DSC).

- Assess long-term stability at 4°C and 25°C for 6 months, evaluating particle size, PDI, and drug content monthly [2].

Protocol 2: Development of Nanoemulsions for Antioxidant Delivery

Objective: To formulate oil-in-water (O/W) nanoemulsions for improving bioavailability of hydrophobic antioxidants.

Materials:

- Carrier oil (e.g., medium-chain triglycerides, olive oil, sesame oil)

- Food-grade surfactants (e.g., lecithin, Tween 20, Span 80)

- Co-surfactant (e.g., ethanol, propylene glycol)

- Antioxidant compound (e.g., curcumin, β-carotene, resveratrol)

- Aqueous phase (deionized water)

Methodology:

Spontaneous Emulsification Method:

- Dissolve the antioxidant in the carrier oil (oil phase).

- Blend surfactant and co-surfactant at appropriate weight ratios (typically 2:1 to 4:1 surfactant:co-surfactant).

- Mix the oil phase with surfactant blend to form a homogeneous mixture.

- Slowly add the aqueous phase dropwise under mild magnetic stirring (300-600 rpm) at room temperature.

- Continue stirring for 30 minutes to achieve equilibrium.

High-Energy Emulsification (Alternative Method):

- Prepare oil and aqueous phases separately.

- Combine phases using high-shear homogenization (10,000-20,000 rpm for 3-5 minutes).

- Further process using high-pressure homogenizer or ultrasonic processor for size reduction.

Characterization:

- Droplet Size Analysis: Use DLS to confirm nanoemulsion formation (<200 nm) [9].

- Thermodynamic Stability: Subject to heating-cooling cycles, freeze-thaw cycles, and centrifugal stress testing.

- Antioxidant Activity Assessment: Compare free vs. encapsulated antioxidant using DPPH/ABTS radical scavenging assays.

- Bioaccessibility Evaluation: Employ simulated gastrointestinal digestion model with intestinal phase sampling and quantification [9].

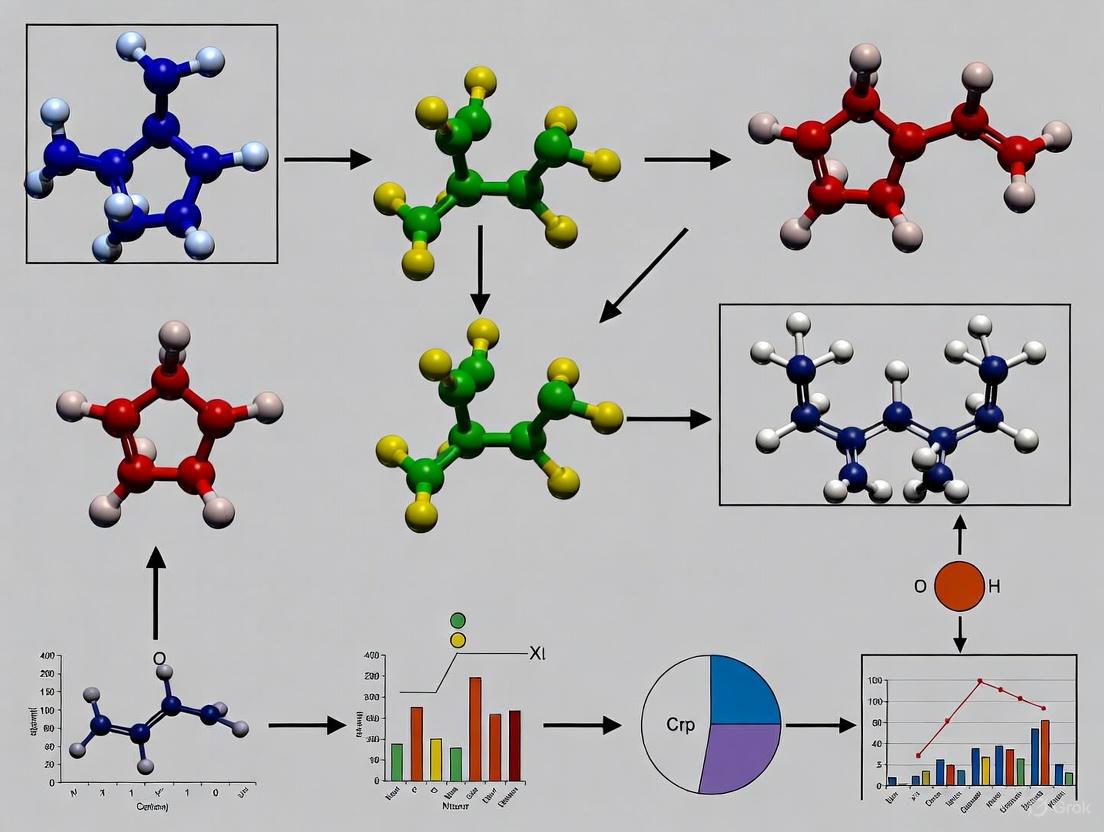

Diagram 1: Nanoemulsion formulation workflow for antioxidant delivery.

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Critical Research Reagents for Nanotechnology-Based Delivery Systems

| Category | Specific Examples | Functionality | Application Notes |

|---|---|---|---|

| Lipid Components | Glyceryl dibehenate (Compritol), Glyceryl monostearate, Medium-chain triglycerides | Form lipid matrix for encapsulation; Enhance solubilization | Select based on drug lipophilicity; Critical for SLNs and NLCs [4] |

| Biodegradable Polymers | PLGA, PLA, Chitosan, Alginate, Gelatin | Controlled release; Mucoadhesion; Protection from degradation | Molecular weight and copolymer ratio affect degradation kinetics [7] [8] |

| Surfactants | Poloxamers, Spans, Tweens, Lecithin | Stabilize nanoparticles; Reduce interfacial tension | HLB value determines applicability for O/W or W/O systems [2] |

| Functionalization Agents | PEG derivatives, Folate, Transferrin, Hyaluronic acid | Stealth properties; Active targeting to specific tissues | PEG molecular weight affects circulation half-life [5] [6] |

| Characterization Reagents | Phosphotungstic acid, Uranyl acetate, Fluorescent dyes (DiO, DiI) | TEM staining; Fluorescent tracking | Critical for visualizing nanocarrier morphology and cellular uptake [5] |

Technological Advancements and Emerging Platforms

Stimuli-Responsive and Targeted Delivery Systems

Recent advances in nanotechnology have enabled the development of "smart" delivery systems that respond to specific physiological stimuli or external triggers. These platforms demonstrate remarkable precision in drug release at target sites, minimizing off-target effects and enhancing therapeutic efficacy.

Nanobubbles represent a particularly innovative platform that utilizes ultrasound-mediated triggering for controlled payload release. These gas-filled nanocarriers (typically <1 μm) can be functionalized with targeting ligands on their surfactant or polymeric shells, enabling site-specific accumulation [10]. Upon exposure to ultrasound at the target tissue, the nanobubbles undergo cavitation, resulting in localized disruption of biological barriers and precise release of encapsulated therapeutics. This approach has shown significant promise in oncology applications, where it enables enhanced penetration of chemotherapeutic agents into tumor tissues while reducing systemic toxicity [10].

Polymeric nanoparticles engineered with environmental responsiveness offer another sophisticated strategy for targeted delivery. These systems can be designed to respond to pH gradients, enzyme activity, or redox potential differences characteristic of specific disease microenvironments [8]. For instance, nanoparticles formulated with pH-sensitive polymers remain stable at physiological pH (7.4) but undergo rapid structural changes or degradation in acidic environments such as tumor tissues (pH 6.5-6.8) or inflammatory sites, resulting in triggered drug release exactly where needed [8].

Hybrid and Combination Approaches

The integration of multiple nanotechnological approaches has generated hybrid systems with synergistic functionality that surpasses the capabilities of individual platforms. These combination strategies address multiple delivery challenges simultaneously, offering comprehensive solutions for particularly problematic compounds.

One prominent example is the incorporation of nanoemulsions within solid dosage forms, which combines the superior solubilization capacity of liquid nanocarriers with the convenience and stability of solid formulations [2]. Solid self-nanoemulsifying drug delivery systems (S-SNEDDS) begin as solid powders or tablets that spontaneously form nanoemulsions upon contact with gastrointestinal fluids, significantly enhancing the absorption of lipophilic compounds [2].

Another emerging hybrid approach combines lipid-based and polymeric nanotechnologies to create nanostructured lipid carriers (NLCs) that offer improved drug loading capacity and stability compared to first-generation solid lipid nanoparticles [4]. By blending solid and liquid lipids in specific ratios, NLCs create a less ordered crystalline structure that provides more space for accommodating drug molecules while maintaining controlled release properties [4].

Diagram 2: Multi-mechanism approach to bioavailability enhancement using nanotechnology.

Characterization and Quality Control Framework

Robust characterization of nanodelivery systems is essential for ensuring reproducible performance, stability, and safety. A comprehensive quality control framework should evaluate multiple physicochemical parameters that directly influence in vivo behavior and therapeutic efficacy.

Critical Quality Attributes (CQAs) for Nanodelivery Systems:

Particle Size and Distribution: Dynamic light scattering provides intensity-based size distribution and polydispersity index (PDI), with values below 0.3 indicating monodisperse systems suitable for predictable in vivo performance [5]. Complementarily, laser diffraction measurements offer volume-based distribution that is less sensitive to small populations of aggregates or oversized particles.

Surface Charge (Zeta Potential): Determined through electrophoretic mobility measurements, zeta potential indicates colloidal stability, with values exceeding |25| mV typically providing sufficient electrostatic repulsion to prevent aggregation [5]. Surface charge also influences protein adsorption, cellular interactions, and biodistribution patterns.

Drug Loading and Encapsulation Efficiency: Quantified through validated analytical methods (HPLC, UV-Vis spectroscopy) after separation of unencapsulated drug, with modern systems achieving loading capacities up to 30% and encapsulation efficiencies exceeding 90% for optimized formulations [7].

In Vitro Release Profile: Utilizing dialysis membranes or flow-through cells under sink conditions, release studies should simulate physiological environments and demonstrate appropriate release kinetics (immediate, sustained, or triggered) for the intended application [8].

Stability Under Storage and Physiological Conditions: Monitoring particle size, PDI, zeta potential, and drug content over time under various storage conditions (4°C, 25°C/60% RH, 40°C/75% RH) provides essential stability data. Additionally, stability in biologically relevant media (simulated gastric/intestinal fluids, plasma) predicts in vivo performance [2].

The implementation of Quality-by-Design (QbD) principles and Process Analytical Technology (PAT) frameworks enables real-time monitoring and control of Critical Process Parameters (CPPs) during nanocarrier manufacturing, ensuring consistent production of materials with desired CQAs [5] [6].

Nanotechnology-based delivery systems represent a sophisticated and highly effective strategy for overcoming the pervasive challenges of poor solubility, instability, and low bioavailability that plague modern pharmaceutical and nutraceutical development. Through various mechanisms including enhanced solubilization, protective encapsulation, modified release kinetics, and targeted delivery, these advanced platforms significantly improve the therapeutic index of bioactive compounds.

The continued advancement of nanodelivery systems requires interdisciplinary collaboration across material science, pharmaceutical technology, and biology. Future research directions should focus on developing more predictive in vitro-in vivo correlation models, establishing standardized regulatory pathways, implementing sustainable and scalable manufacturing processes, and further personalizing delivery approaches based on individual patient characteristics and disease states. As these technologies mature, they hold tremendous potential to revolutionize treatment paradigms across diverse therapeutic areas and bring previously undeliverable compounds to clinical application.

Nanocarriers are advanced transport and encapsulation systems, typically between 1 and 1000 nm in size, designed to protect active ingredients and enhance their delivery to specific sites of action [11]. In the context of enhanced nutrient delivery, these systems address critical challenges such as poor solubility, chemical instability, and low bioavailability of many bioactive compounds [12] [3]. By improving the dispersibility, stability, and targeted release of nutrients, nanocarriers significantly increase their therapeutic efficacy and safety profile [11]. The global nutraceuticals market, valued at USD 417.66 billion in 2020, is a key driver for the development of these advanced delivery systems, with nanotechnology offering promising solutions to overcome the limitations of conventional formulations [12]. This review provides a comparative analysis of four major nanocarrier systems—liposomes, polymeric nanoparticles, solid lipid nanoparticles, and metal-based systems—focusing on their characteristics, applications, and experimental protocols for nutrient delivery.

Comparative Analysis of Nanocarrier Systems

The table below summarizes the key characteristics, advantages, and nutrient delivery applications of the four primary nanocarrier systems.

Table 1: Comparative analysis of nanocarrier systems for nutrient delivery

| Nanocarrier Type | Key Composition | Size Range (nm) | Key Advantages for Nutrient Delivery | Limitations | Nutrient Delivery Applications |

|---|---|---|---|---|---|

| Liposomes | Phospholipid bilayers [13] | ~50 - 1000 [14] | Biocompatible; capacity for hydrophilic and hydrophobic compounds [13] | Instability, potential for burst release [13] | Vitamins, omega-3 fatty acids, antioxidants [12] [3] |

| Polymeric NPs | Biodegradable polymers (e.g., PLGA, chitosan) [15] [16] | 1 - 1000 [11] | Controlled, programmable release; high encapsulation efficiency [13] [15] | Batch-to-batch variability; potential residual toxicity [13] | Curcumin, polyphenols, plant extracts [15] |

| Solid Lipid NPs (SLNs) & NLCs | Solid lipid matrices (SLNs), blend of solid & liquid lipids (NLCs) [13] | Not specified in results | Improved stability vs. liposomes; reduced premature leakage; high biocompatibility [13] | Limited drug loading capacity (SLNs); potential cytotoxicity concerns [13] | Lipophilic vitamins, carotenoids, curcumin [12] [15] |

| Metal-Based NPs | Inorganic metals (e.g., gold, silver, zinc, selenium) [16] | Not specified in results | Unique theranostic potential; stimuli-responsive release [13] | Non-biodegradability; potential long-term accumulation; toxicity concerns [13] | Trace minerals (Zn, Se); research stage for other nutrients [16] |

Experimental Protocols for Nanocarrier Evaluation

Protocol: Formulation and Characterization of Lipid-Based Nanocarriers

This protocol details the preparation and basic characterization of lipid nanocarriers, such as Solid Lipid Nanoparticles (SLNs), for encapsulating lipophilic nutrients (e.g., curcumin, vitamin D, omega-3 fatty acids).

1. Materials and Reagents

- Lipids: Glyceryl monostearate, Compritol 888 ATO, or Precirol ATO 5 as solid lipids; Miglyol 812 or oleic acid as liquid lipids for NLCs [13].

- Surfactants: Poloxamer 188, Tween 80, or lecithin for emulsion stabilization [13].

- Active Nutrient: Lipophilic compound (e.g., curcumin).

- Solvents: Ethanol or acetone for lipid dissolution.

- Aqueous Phase: Ultrapure water or phosphate-buffered saline (PBS).

2. Equipment

- High-shear homogenizer or probe sonicator.

- Magnetic stirrer with hot plate.

- Zetasizer or similar instrument for particle size and zeta potential analysis.

3. Methodology

- Step 1: Lipid Phase Preparation. Melt the solid lipid (e.g., 500 mg) at approximately 5-10°C above its melting point. Dissolve the nutrient (e.g., 50 mg curcumin) into the molten lipid. For NLCs, blend solid and liquid lipids prior to melting [13].

- Step 2: Aqueous Phase Preparation. Heat the aqueous surfactant solution (e.g., 1% Poloxamer 188 in 50 mL water) to the same temperature as the lipid phase.

- Step 3: Emulsification. Add the hot lipid phase to the hot aqueous phase under high-speed stirring (e.g., 10,000 rpm for 5 minutes) using a homogenizer to form a coarse pre-emulsion.

- Step 4: Size Reduction. Process the hot pre-emulsion using a probe sonicator (e.g., 70% amplitude, 5 minutes, cycles of 10s on/5s off) to form a nanoemulsion.

- Step 5: Solidification. Cool the nanoemulsion rapidly under mild stirring (500 rpm) at 4°C to recrystallize the lipid and form solid nanoparticles.

- Step 6: Purification. Centrifuge or dialyze the nanoparticle dispersion to remove free, unencapsulated nutrient and excess surfactant.

4. Characterization

- Particle Size and Polydispersity Index (PDI): Analyze by Dynamic Light Scattering (DLS). Dilute the formulation 1:100 in purified water and measure. PDI < 0.3 indicates a monodisperse population [13].

- Zeta Potential: Measure electrophoretic mobility to assess surface charge and colloidal stability. Values > |±30| mV indicate good physical stability [13].

- Entrapment Efficiency (EE): Separate unentrapped nutrient by ultracentrifugation (e.g., 25,000 rpm for 30 min). Analyze the supernatant spectrophotometrically or via HPLC. Calculate EE% = (Total nutrient added - Free nutrient in supernatant) / Total nutrient added × 100 [15].

Protocol: In Vitro Evaluation of Nutrient Release and Bioaccessibility

1. Materials and Reagents

- Simulated Gastric Fluid (SGF): 0.32% pepsin in 0.03 M NaCl, pH adjusted to 2.0 with HCl.

- Simulated Intestinal Fluid (SIF): 1% pancreatin and 0.15% bile salts in PBS, pH adjusted to 7.4.

- Dialysis membrane tubing (e.g., 12-14 kDa MWCO).

2. Methodology

- Step 1: Gastric Phase. Mix 10 mL of nanocarrier dispersion with 10 mL of SGF. Incubate in a shaking water bath at 37°C and 100 rpm for 2 hours.

- Step 2: Intestinal Phase. Adjust the pH of the gastric digest to 7.4 using 1M NaOH. Add 20 mL of SIF and continue incubation for a further 2-4 hours.

- Step 3: Sampling. At predetermined time points, withdraw 1 mL aliquots from the release medium and replace with an equal volume of fresh medium to maintain sink conditions.

- Step 4: Analysis. Quantify the released nutrient concentration in the aliquots using a validated analytical method (e.g., UV-Vis spectrophotometry or HPLC). Plot the cumulative release percentage over time to generate a release profile.

Visualization of Nanocarrier Design and Evaluation Workflow

The following diagram illustrates the logical workflow for the design, formulation, and evaluation of nanocarriers for nutrient delivery, integrating the protocols described above.

Figure 1. A structured workflow for developing nutrient-loaded nanocarriers, from initial design to performance evaluation.

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 2: Key research reagents and materials for nanocarrier development

| Reagent/Material | Function/Application | Examples/Specific Types |

|---|---|---|

| Lipids | Core structural material for lipid-based nanocarriers [13] | Glyceryl monostearate (SLNs), Miglyol 812 (NLCs), Phospholipids (Liposomes) [13] |

| Biodegradable Polymers | Form the matrix of polymeric nanoparticles for controlled release [15] | PLGA, PLGA-PEG, Chitosan [15] |

| Surfactants & Stabilizers | Stabilize nanoemulsions during formation and prevent aggregation [13] | Poloxamer 188, Tween 80, Lecithin [13] |

| Active Nutrients | Bioactive compounds to be encapsulated and delivered [12] [15] | Curcumin, Vitamins (B12, C, D), Omega-3 fatty acids, Carotenoids [12] [3] [15] |

| Characterization Instruments | Analyze critical quality attributes of the final nanocarrier formulation [13] | DLS/Zetasizer (Size/Zeta Potential), HPLC (Encapsulation Efficiency), Spectrophotometer [13] [15] |

The comparative analysis presented herein underscores the significant potential of nanocarrier systems to revolutionize nutrient delivery. Liposomes, polymeric NPs, lipid NPs, and metal-based systems each offer a distinct set of advantages tailored to overcome the specific physicochemical and pharmacokinetic challenges of bioactive nutrients. The provided application notes and standardized protocols offer a foundational framework for researchers to systematically develop, characterize, and evaluate these advanced systems. Future research should focus on addressing translational challenges, including long-term safety assessments, scalable manufacturing processes, and the development of clear regulatory pathways to fully realize the potential of nanotechnology in enhancing global nutrition and health.

Nanotechnology has revolutionized targeted delivery by leveraging the unique properties of materials at the nanoscale (typically 1-1000 nm) to overcome biological barriers. These nanocarriers are designed to enhance the solubility, stability, and bioavailability of therapeutic agents, while simultaneously reducing their side effects through improved targeting precision [17]. The core mechanisms of action—Enhanced Permeability and Retention (EPR) for passive targeting and ligand-receptor interactions for active targeting—enable these systems to accumulate preferentially at disease sites, particularly in inflamed tissues and tumors [18]. This application note details the quantitative parameters, experimental protocols, and practical methodologies for utilizing these mechanisms in enhanced nutrient and drug delivery systems research.

Core Mechanisms and Quantitative Parameters

Passive Targeting: The Enhanced Permeability and Retention (EPR) Effect

The EPR effect is a cornerstone phenomenon in nanomedicine that enables passive accumulation of nanocarriers in pathological tissues. Tumor and inflamed tissues possess abnormal, leaky blood vessels with gaps between endothelial cells ranging from 100 to 2000 nm, significantly larger than the 5-10 nm gaps found in normal vasculature [18]. This structural disparity allows nanoscale particles to extravasate and accumulate in the interstitial space, where impaired lymphatic drainage further promotes their retention.

Table 1: Quantitative Parameters Governing the EPR Effect

| Parameter | Optimal Range for EPR | Biological Significance | Measurement Techniques |

|---|---|---|---|

| Particle Size | 10-200 nm | Prevents renal filtration (<10 nm) and enables extravasation through endothelial gaps | Dynamic Light Scattering (DLS) |

| Surface Charge | Slightly negative to neutral (-10 to +10 mV) | Reduces opsonization and prolongs systemic circulation | Zeta Potential Measurement |

| Polymeric Coating | PEG density: 5-20% by mass | Creates steric hindrance, reduces RES uptake, increases circulation half-life | NMR Spectroscopy, HPLC |

| Vascular Permeability | Gap sizes: 100-2000 nm | Enables nanocarrier extravasation from compromised vasculature | Intravital Microscopy |

| Lymphatic Drainage | Impaired in tumor tissues | Increases retention of extravasated nanocarriers | Radioactive Tracer Studies |

Active Targeting: Ligand-Receptor Interactions

Active targeting enhances delivery specificity through molecular recognition. This approach utilizes surface-functionalized nanocarriers decorated with targeting ligands that bind specifically to receptors overexpressed on target cells. The binding affinity (Kd) between ligand and receptor typically ranges from nM to μM concentrations, ensuring selective cellular uptake via receptor-mediated endocytosis [17] [18].

Table 2: Active Targeting Ligands and Their Applications

| Ligand Type | Target Receptor | Expression Profile | Binding Affinity (Kd) | Nanocarrier Conjugation Efficiency |

|---|---|---|---|---|

| Folic Acid | Folate Receptor | Overexpressed in ovarian, breast, lung cancers | 0.1-1 nM | 70-90% via carboxyl group conjugation |

| Transferrin | Transferrin Receptor | Ubiquitous in tumor cells for iron transport | 5-30 nM | 60-80% via amine coupling |

| RGD Peptide | αvβ3 Integrin | Angiogenic endothelial cells | 10-100 nM | 50-70% via thiol-maleimide chemistry |

| Hyaluronic Acid | CD44 Receptor | Cancer stem cells, metastatic cells | 1-10 μM | 80-95% via EDC/NHS chemistry |

| Aptamers | Various protein targets | Cell-type specific | 1-100 nM | 60-85% via thiol-gold binding |

Experimental Protocols and Methodologies

Protocol: Preparation of Ligand-Targeted Polymeric Nanoparticles

Objective: Synthesize and characterize folate-receptor targeted PLGA nanoparticles for enhanced cellular uptake.

Materials:

- Poly(D,L-lactide-co-glycolide) (PLGA): 50:50 monomer ratio, acid-terminated (10% w/v in acetone)

- Folate-PEG-NH₂: Molecular weight 5,000 Da (2 mg/mL in DMSO)

- EDC/NHS crosslinking kit: for carboxyl-amine conjugation

- Dialysis membrane: MWCO 12-14 kDa

- Phosphate Buffered Saline (PBS): pH 7.4

- Dynamic Light Scattering instrument: for size and zeta potential analysis

Procedure:

Nanoparticle Formation:

- Dissolve 100 mg PLGA in 1 mL acetone under magnetic stirring at 500 rpm

- Add the organic phase dropwise to 4 mL of 2% polyvinyl alcohol (PVA) solution

- Emulsify using probe sonication at 70 W for 2 minutes in an ice bath

- Stir overnight for solvent evaporation and nanoparticle hardening

Surface Functionalization:

- Activate nanoparticle surface carboxyl groups with EDC/NHS (molar ratio 1:2:1) for 30 minutes

- Add folate-PEG-NH₂ at 1:10 molar ratio to activated carboxyl groups

- React for 12 hours at 4°C with gentle stirring

- Purify by centrifugation at 15,000 × g for 20 minutes

Characterization:

- Determine particle size and PDI by DLS: Dilute nanoparticles 1:100 in distilled water

- Measure zeta potential in 1 mM KCl at pH 7.4

- Calculate encapsulation efficiency: HPLC analysis of drug content in supernatant vs. pellet

- Confirm ligand conjugation: X-ray Photoelectron Spectroscopy (XPS) for nitrogen signature

Protocol: In Vitro Evaluation of Cellular Uptake and Targeting Efficiency

Objective: Quantify the targeting specificity and cellular internalization of functionalized nanoparticles.

Cell Culture Preparation:

- Maintain KB cells (folate receptor-positive) and A549 cells (folate receptor-negative) in folate-free RPMI 1640 medium with 10% FBS

- Seed cells in 12-well plates at density of 1 × 10⁵ cells/well and incubate for 24 hours

Cellular Uptake Assay:

- Fluorescent Labeling: Load nanoparticles with 0.1% coumarin-6 during formulation

- Treatment: Incubate cells with targeted and non-targeted nanoparticles (100 μg/mL) for 1, 2, and 4 hours at 37°C

- Competition Study: Pre-treat KB cells with free folic acid (1 mM) for 30 minutes before adding targeted nanoparticles

- Analysis:

- Wash cells 3× with cold PBS

- Lyse with 1% Triton X-100 in PBS

- Measure fluorescence at Ex/Em 458/540 nm using microplate reader

- Normalize to protein content using BCA assay

Quantitative Analysis:

- Calculate targeting index = (Uptake of targeted NPs in KB cells) / (Uptake of non-targeted NPs in KB cells)

- Determine specificity ratio = (Uptake in KB cells) / (Uptake in A549 cells)

- Significant targeting is indicated by index >2.0 and specificity ratio >3.0

Visualization of Core Mechanisms

EPR Effect and Active Targeting Pathway

Nanocarrier Design and Formulation Workflow

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Critical Reagents for Nanocarrier Development and Evaluation

| Reagent/Material | Supplier Examples | Function/Application | Optimal Concentration |

|---|---|---|---|

| PLGA (50:50) | Sigma-Aldrich, Lactel | Biodegradable polymer matrix for controlled release | 5-10% w/v in organic solvent |

| DSPE-PEG(2000)-COOH | Avanti Polar Lipids | Provides stealth properties and conjugation sites | 1-5 mol% of total lipid |

| EDC/NHS Crosslinker | Thermo Fisher | Activates carboxyl groups for ligand conjugation | 2:1 molar ratio to COOH groups |

| Sulfo-Cy5 NHS Ester | Lumiprobe | Fluorescent labeling for tracking studies | 0.1-0.5% mol ratio to polymer |

| Matrigel Matrix | Corning | 3D cell culture for penetration studies | 100% at 4°C, gels at 37°C |

| Transwell Inserts | Costar | Permeability and transport studies | 0.4-8.0 μm pore sizes |

| Folate-Free RPMI 1640 | Gibco | Selective culture of folate receptor-positive cells | Supplement with 10% dialyzed FBS |

| Dynamic Light Scattering Instrument | Malvern Instruments | Size and zeta potential analysis | 0.1-1 mg/mL nanoparticle concentration |

Analytical Methods and Data Interpretation

Key Performance Metrics and Acceptance Criteria

Successful nanocarrier systems should meet the following benchmarks:

Physicochemical Properties:

- Size distribution: 50-150 nm with PDI <0.2

- Zeta potential: -10 to -30 mV for colloidal stability

- Encapsulation efficiency: >80% for hydrophobic actives, >50% for hydrophilic

- Drug loading capacity: >5% w/w

Biological Performance:

- Cellular uptake: >2-fold increase compared to non-targeted controls

- Specificity index: >3-fold preference for target vs. non-target cells

- In vivo tumor accumulation: >5% ID/g tissue at 24 hours post-injection

- Therapeutic index: >2-fold improvement compared to free drug

Troubleshooting Common Formulation Challenges

Problem 1: Broad Size Distribution (PDI >0.3)

- Cause: Inadequate homogenization during emulsion formation

- Solution: Optimize sonication parameters (time, amplitude, pulse settings)

- Alternative: Utilize microfluidic mixing for improved reproducibility

Problem 2: Low Ligand Conjugation Efficiency

- Cause: Steric hindrance or insufficient activation of functional groups

- Solution: Introduce spacer arms (PEG chains) between nanoparticle and ligand

- Alternative: Use click chemistry approaches for higher efficiency

Problem 3: Rapid Clearance In Vivo

- Cause: Protein opsonization and RES uptake

- Solution: Increase PEG density to 10-15% and ensure complete surface coverage

- Alternative: Utilize alternative stealth polymers like poly(2-oxazoline)

The protocols and mechanisms outlined provide a robust framework for developing enhanced delivery systems that leverage nanoscale properties for improved therapeutic outcomes in nutrient and drug delivery applications.

Precision delivery represents a paradigm shift in therapeutic administration, aiming to maximize drug efficacy at the target site while minimizing off-target side effects. By leveraging advanced nanocarrier systems, this approach fundamentally improves the pharmacokinetics and biodistribution of active pharmaceutical ingredients (APIs) [7]. The core rationale hinges on protecting therapeutic cargos from degradation, controlling their release profiles, and directing them to specific tissues, cells, or even subcellular compartments [19] [20]. This is particularly critical for potent chemotherapeutic agents and fragile biologics, such as mRNA and siRNA, which require stringent protection and precise localization to exert their therapeutic action [21]. The transition from conventional drug delivery to precision nanocarrier-based systems thereby addresses key challenges in modern medicine, including systemic toxicity, poor bioavailability, and therapeutic resistance.

The Imperative for Precision Delivery: Core Therapeutic Challenges

Traditional drug administration, such as oral or intravenous delivery of free drugs, often fails to achieve therapeutic concentrations at the disease site and is associated with widespread systemic distribution. This leads to two fundamental problems: dose-limiting toxicities and suboptimal efficacy [21] [20].

- Reducing Systemic Toxicity: Chemotherapeutic agents like doxorubicin are highly effective but can cause severe damage to healthy tissues, notably cardiotoxicity. Encapsulation within nanocarriers like liposomes (e.g., Doxil) shields healthy tissues from the drug during circulation, reducing side effects and improving the therapeutic index [21].

- Overcoming Biological Barriers: Naked nucleic acids (siRNA, mRNA) are rapidly degraded by nucleases in the bloodstream and cannot passively cross cell membranes. Lipid Nanoparticles (LNPs) protect these fragile payloads and facilitate their cellular uptake, enabling novel gene therapies and vaccines [21].

- Enhancing Bioavailability and Compliance: Many drugs, especially those administered orally, suffer from low bioavailability or require frequent dosing due to short half-lives. Nano-encapsulation can modulate release kinetics, prolong therapeutic effect, and reduce dosing frequency, thereby improving patient compliance [20].

A diverse array of nanocarriers has been engineered to address different delivery challenges. Their unique physicochemical properties determine drug loading capacity, release profile, circulation time, and targeting capability [22] [7].

Table 1: Characteristics of Major Nanocarrier Platforms for Precision Delivery

| Nanocarrier Type | Key Composition | Therapeutic Rationale & Advantages | Exemplary Clinical Application |

|---|---|---|---|

| Liposomes | Phospholipids, Cholesterol [19] | Biocompatible; co-delivery of hydrophilic/hydrophobic drugs; reduced systemic toxicity [21] | Doxil (doxorubicin) for cancer; Vyxeos (cytarabine/daunorubicin) for leukemia [21] |

| Lipid Nanoparticles (LNPs) | Ionizable lipids, phospholipids, PEG-lipids [7] | Superior protection of nucleic acids (mRNA, siRNA); efficient cellular delivery [21] | Onpattro (siRNA) for hATTR; COVID-19 mRNA vaccines (Spikevax, Comirnaty) [21] |

| Polymeric Nanoparticles | PLGA, Chitosan [19] | High stability and controlled drug release; tunable degradation rates [19] | BIND-014 (docetaxel-loaded targeted nanoparticles for cancer) [21] |

| Inorganic Nanoparticles | Mesoporous Silica, Gold [7] | Tunable porosity; functionalizable surface; potential for photothermal therapy [7] | Cornell Dots (C' Dots) - silica nanoparticles for imaging and drug delivery [21] |

Key Strategies for Targeted Delivery

The journey of a nanocarrier from administration to intracellular target is complex. Precision delivery employs a multi-faceted strategy to navigate this journey.

Passive vs. Active Targeting

- Passive Targeting: This approach leverages the inherent pathological features of tissues, such as the leaky vasculature and poor lymphatic drainage commonly found in tumors. This allows nanocarriers of a specific size (typically 10-200 nm) to extravasate and accumulate selectively, a phenomenon known as the Enhanced Permeability and Retention (EPR) effect [19]. It is the underlying mechanism for the success of untargeted systems like Doxil [21].

- Active Targeting: This strategy involves functionalizing the surface of nanocarriers with targeting ligands (e.g., antibodies, peptides, small molecules, carbohydrates) that recognize and bind to specific receptors overexpressed on the surface of target cells [22]. This facilitates receptor-mediated endocytosis, enhancing cellular uptake and specificity. Examples include HER2-targeting for breast cancer and ligand-based targeting of liver cells [22] [21].

Subcellular Targeting: The Nuclear Challenge

For many therapeutics, particularly gene-editing tools and DNA-intercalating chemotherapies, the nucleus is the ultimate site of action. Nuclear targeting represents a significant challenge, requiring the nanocarrier to not only enter the target cell but also escape the endo/lysosomal compartment and traverse the nuclear membrane [19]. Strategies to achieve this include:

- Passive Nuclear Entry: Modulating nanocarrier properties (size, shape, surface charge) to facilitate diffusion through nuclear pore complexes [19].

- Active Nuclear Targeting: Decorating nanocarriers with Nuclear Localization Signals (NLS), which are recognized by importin proteins that actively transport cargo across the nuclear membrane [19].

The following diagram illustrates the multi-stage journey of an actively targeted, nuclear-seeking nanocarrier.

Experimental Protocols for Nanocarrier Evaluation

Protocol 1: In Vitro Assessment of Nanocarrier Payload Delivery and Endosomal Escape

Objective: To quantitatively evaluate the efficiency of cellular uptake and intracellular payload release of nanocarriers, specifically their ability to escape endo/lysosomal compartments [23].

Background: A critical bottleneck in nanocarrier-mediated delivery is the tendency for particles to be trapped and degraded within endosomes. This protocol uses a genetically engineered galectin-8 (Gal8-mRuby) reporter system, which fluoresces upon endosomal membrane disruption, providing a direct readout of successful escape [23].

Materials:

- Gal8-mRuby Reporter Cell Line: Genetically modified mouse or human cells expressing the fluorescent protein mRuby fused to galectin-8 [23].

- Polymer Library & Formulation Reagents: Biodegradable polymer nanoparticles (e.g., PLGA, chitosan), lipids for LNPs, solvents, and equipment for nanoprecipitation or microfluidics [7] [23].

- Fluorescence Microscopy & HCS System: High-content screening microscope with capabilities for automated image acquisition and analysis.

- Analysis Software: ImageJ or commercial HCS analysis software (e.g., CellProfiler).

Procedure:

- Seed Reporter Cells: Plate Gal8-mRuby cells in a 96-well optical-bottom plate at a density of 1x10^4 cells/well and culture for 24 hours.

- Apply Nanocarriers: Treat cells with the nanocarrier library at a standardized concentration (e.g., 100 µg/mL) for 4-6 hours.

- Wash and Image: Gently wash wells with PBS to remove non-internalized particles. Acquire high-resolution fluorescence images for both the nanoparticle signal (e.g., green fluorescence) and the Gal8-mRuby signal (orange-red).

- Quantitative Image Analysis:

- Use analysis software to identify individual cells and quantify the total fluorescence intensity per cell for both channels.

- Calculate an "Escape Ratio" for each formulation:

(Gal8-mRuby Intensity) / (Nanoparticle Intensity). - Normalize this ratio to negative control (untreated cells) and positive control (a known efficient delivery agent, e.g., a commercial transfection reagent).

Interpretation: A high Escape Ratio indicates that the nanocarrier formulation is highly efficient at disrupting the endosomal membrane and releasing its payload into the cytosol. Top-performing formulations from this in vitro screen show a high positive correlation with successful gene delivery performance in subsequent in vivo models [23].

Protocol 2: In Vivo Evaluation of Organ-Specific Tropism

Objective: To determine the biodistribution and organ-specific targeting efficiency of nanocarrier formulations in a live animal model.

Background: The chemical properties of nanocarriers (e.g., lipid structure, surface charge, PEGylation) can dramatically alter their in vivo fate. This protocol uses mRNA encoding a luciferase reporter to non-invasively track functional delivery to various organs [23].

Materials:

- Animal Model: C57BL/6 mice (6-8 weeks old).

- Nanocarrier Formulations: LNPs or polymeric NPs loaded with luciferase-encoding mRNA.

- IVIS Imaging System: In Vivo Imaging System or similar for bioluminescence detection.

- D-Luciferin Substrate: Potassium salt, prepared in PBS.

- Analysis Software: Living Image or equivalent.

Procedure:

- Formulate and Inject: Prepare nanocarriers encapsulating luciferase mRNA. Administer a single dose (e.g., 0.5 mg/kg mRNA) via intravenous injection into the tail vein of mice (n=5 per group).

- Image Bioluminescence:

- At 6, 24, and 48 hours post-injection, inject mice intraperitoneally with D-luciferin (150 mg/kg).

- Anesthetize mice and place them in the IVIS chamber 10 minutes after luciferin injection.

- Acquire bioluminescence images using a standardized acquisition time.

- Quantify Biodistribution: Using the imaging software, define regions of interest (ROIs) over major organs (liver, spleen, lungs). Quantify the total flux (photons/second) within each ROI.

- Ex Vivo Validation: After the final time point, euthanize the animals, harvest key organs, and perform ex vivo imaging to confirm signal localization.

Interpretation: The primary organs showing strong bioluminescence signal indicate the natural tropism of the nanocarrier formulation. As reported, fine-tuning chemical properties can steer nanoparticles to specific tissues, such as endothelial cells in the lungs or B cells in the spleen [23].

Table 2: Key Reagents for Precision Delivery Research

| Research Reagent / Tool | Function and Rationale |

|---|---|

| Ionizable Cationic Lipids | Critical component of LNPs; promotes self-assembly, endosomal escape via destabilization of the endosomal membrane at low pH [21]. |

| PEGylated Lipids | Imparts a "stealth" property by reducing opsonization and protein corona formation, thereby extending systemic circulation time [19]. |

| Targeting Ligands (e.g., Antibodies, Peptides, Folate) | Confers active targeting specificity by binding to receptors overexpressed on target cells (e.g., HER2, PSMA, folate receptor) [22] [21]. |

| Gal8-mRuby Reporter Cell Line | A crucial in vitro tool for high-throughput screening of nanocarrier formulations based on their true functional payload delivery capability [23]. |

| Stimuli-Responsive Linkers (pH, Redox, Enzyme) | Enables controlled drug release at the target site (e.g., in the acidic tumor microenvironment or in the presence of specific enzymes like cathepsin B) [22] [19]. |

Critical Analysis and Future Directions

Despite the compelling rationale and promising preclinical data, the clinical translation of actively targeted nanocarriers has been limited. Many targeted formulations have failed to show significant improvement over untargeted counterparts or standard therapies in clinical trials [21]. A meta-analysis of over 200 preclinical studies showed no significant in vivo improvement in delivery efficiency with targeted versus untargeted nanoparticles [21].

Key challenges include:

- Complex Pharmacokinetics: Conjugating targeting ligands (e.g., antibodies) to nanoparticles can paradoxically shorten their circulation half-life, reducing the time window for target accumulation [21].

- Antigen Depletion and Heterogeneity: Targeted nanoparticles may induce the downregulation of their target antigens on cancer cells, similar to phenomena observed with Antibody-Drug Conjugates (ADCs), thereby limiting efficacy [21].

- The Protein Corona: Upon intravenous administration, nanoparticles are rapidly coated with serum proteins, which can mask targeting ligands and fundamentally alter their biological identity and destination [19].

Future strategies must pivot towards a deeper understanding of nano-bio interactions. This includes standardizing dosing metrics (moving beyond mass/kg to particles/kg) [21], developing smarter, biologically informed materials that respond to disease microenvironments, and leveraging insights from clinically successful but untargeted systems like Doxil and LNPs. The ultimate goal remains the rational design of precision delivery systems that reliably and safely bridge the gap between in vitro potential and in vivo clinical efficacy.

Synthesis and Application: Developing and Deploying Nano-Formulations

The synthesis methodology employed in creating nanoparticles (NPs) is a critical determinant of their physicochemical properties, biological interactions, and overall suitability for advanced applications, particularly in nutrient delivery systems. The selection between physical, chemical, and green synthesis approaches involves balancing control over nanoparticle characteristics with environmental, safety, and scalability considerations [24] [25]. For researchers developing enhanced nutrient delivery systems, understanding these trade-offs is essential for designing nanoparticles with optimal bioavailability, targeted release profiles, and minimal toxicity [26]. This review provides a comprehensive comparison of these synthesis methodologies, with a specific focus on their applicability in nanoscale nutrient carrier development, featuring structured experimental protocols and analytical frameworks to guide research implementation.

Comparative Analysis of Synthesis Approaches

Table 1: Comprehensive Comparison of Primary Nanoparticle Synthesis Methodologies

| Parameter | Physical Methods | Chemical Methods | Green Synthesis |

|---|---|---|---|

| General Principle | Top-down approach using physical forces to break bulk materials [27] | Bottom-up approach using chemical reducing agents [24] [27] | Bottom-up approach using biological extracts as reducers [24] [28] |

| Key Techniques | Vapor deposition, pulsed laser ablation, microwave irradiation, gamma radiation [27] | Chemical reduction, microemulsions, electrochemical synthesis, polyol method [27] | Plant extract-mediated, microbial (bacterial, fungal, algal) synthesis [25] [28] |

| Typical Energy Requirements | High energy input [24] | Moderate energy input [24] | Low energy input [24] [28] |

| Production Cost | High (expensive equipment) [27] | Moderate [27] | Low (utilizes renewable resources) [28] |

| Environmental Impact | Low chemical waste but high energy consumption [24] | High (toxic solvents and byproducts) [24] [29] | Minimal waste, sustainable, and eco-friendly [24] [25] |

| Scalability | Challenging for industrial scale [27] | Highly scalable [27] | Promising for large-scale production [28] |

| Particle Size Control | Moderate [27] | Excellent (via precursor concentration & reaction kinetics) [27] | Good (dependent on biological source and conditions) [28] |

| Shape Control | Limited [27] | Excellent [27] | Moderate [28] |

| Sample Purity | High [27] | Often requires purification from toxic precursors [29] | High, with inherent biocompatibility [29] [28] |

| Common Capping/Stabilizing Agents | Varies | Synthetic polymers (e.g., PVP, PVA), citrate [27] | Natural phytochemicals (e.g., flavonoids, phenolics) [28] [27] |

| Toxicity Concerns | Low, but depends on the method | High due to toxic chemical residues [29] [27] | Low cytotoxicity and high biocompatibility [29] [28] |

| Key Advantages | High purity, no solvent contamination [27] | High yield, good control over size/shape [27] | Eco-friendly, non-toxic, cost-effective, biodegradable [24] [28] |

| Major Limitations | High cost, broad size distribution, low yield [27] | Hazardous chemicals, environmental pollution [24] [27] | Batch-to-batch variability, standardization challenges [25] [28] |

Table 2: Suitability for Nutrient Delivery Applications

| Application Requirement | Physical Methods | Chemical Methods | Green Synthesis |

|---|---|---|---|

| Biocompatibility | Moderate | Low (requires extensive purification) | High [29] [28] |

| Controlled Release Kinetics | Moderate | High (tunable matrix) | High (e.g., biodegradable polymers) [26] |

| Targeting Efficiency | Low | High (surface functionalization) | High (inherent bioactivity) [25] |

| Encapsulation Efficiency | Low | High | High [30] [9] |

| Regulatory Pathway | Complex | Complex (safety concerns) | Simpler (biocompatible profile) [25] |

| Oral Bioavailability Enhancement | Limited | Good (with surface engineering) | Excellent (improved uptake & stability) [9] |

Synthesis Protocols for Nutrient Delivery Systems

Protocol: Plant-Mediated Green Synthesis of Metal Nanoparticles for Nutrient Encapsulation

Principle: Utilizes phytochemicals from plant extracts as reducing and stabilizing agents to form biocompatible metal nanoparticles suitable for nutrient loading [29] [28].

Materials:

- Plant Material: Leaves of Terminalia catappa (for Fe NPs) or Tridax procumbens (for Zn NPs) [29]

- Precursor Salts: FeCl₃·6H₂O (for iron NPs) or Zn(NO₃)₂·6H₂O (for zinc NPs) [29]

- Equipment: Heating mantle, centrifuge, magnetic stirrer, UV-Vis spectrophotometer, drying oven [29]

Procedure:

- Plant Extract Preparation: Wash 20 g of fresh plant leaves and air-dry. Cut into small pieces and crush in 200 mL of distilled water. Boil the mixture at 70-80°C for 30 minutes. Filter through Whatman No. 1 filter paper and centrifuge at 1000 rpm for 5 minutes to remove debris. Store the supernatant as plant extract [29].

- Nanoparticle Synthesis: Prepare a 0.01 M solution of metal salt (e.g., 0.297 g Zn(NO₃)₂·6H₂O in 100 mL water). Mix the metal salt solution with plant extract at a 1:1 ratio under constant stirring for 1-2 hours. Observe color change indicating nanoparticle formation (black for iron NPs, pale white for zinc NPs) [29].

- Purification and Recovery: Allow the mixture to stand undisturbed for 3 hours. Centrifuge at 5000 rpm for 30 minutes. Collect the pellet and wash twice with distilled water. Dry the nanoparticles at 150°C for 2 hours (iron NPs) or calcinate at 500°C for 2 hours (zinc oxide NPs) [29].

- Nutrient Loading: For nutrient encapsulation, add the bioactive compound (e.g., antioxidants, vitamins) during the synthesis stage or employ post-synthesis loading through incubation [9].

Critical Parameters:

- Plant Selection: Different plants yield nanoparticles with varying properties due to their unique phytochemical profiles [28].

- Extract Concentration: Influences reduction rate and final particle size [28].

- Reaction Temperature: Optimal range typically 60-80°C for efficient synthesis [29].

- pH: Affects nanoparticle morphology and stability [28].

Protocol: Chemical Synthesis of Polymeric Nanoparticles for Nutrient Delivery

Principle: Utilizes biodegradable polymers to form nanocarriers through self-assembly or emulsion-based methods for encapsulating both hydrophilic and hydrophobic nutrients [26] [30].

Materials:

- Polymers: PLGA, chitosan, alginate, or polycaprolactone (PCL) [26] [30]

- Surfactants: Polysorbates, phospholipids, or polyethylene glycol (PEG) [30]

- Organic Solvents: Ethyl acetate, dichloromethane (analytical grade)

- Equipment: Probe sonicator, magnetic stirrer, rotary evaporator

Procedure (Single Emulsion Technique for Lipid-Soluble Nutrients):

- Organic Phase Preparation: Dissolve 100 mg of polymer (e.g., PLGA) and 10 mg of nutrient compound (e.g., lipophilic antioxidant) in 5 mL of organic solvent (e.g., dichloromethane) [30].

- Aqueous Phase Preparation: Prepare 20 mL of surfactant solution (e.g., 1% PVA in water) [30].

- Emulsification: Add the organic phase dropwise to the aqueous phase while probe sonicating at 100 W for 2-3 minutes to form an oil-in-water emulsion [30].

- Solvent Evaporation: Stir the emulsion overnight at room temperature to evaporate the organic solvent. Alternatively, use reduced pressure rotary evaporation [30].

- Purification: Centrifuge the nanoparticle suspension at 15,000 rpm for 30 minutes. Wash twice with distilled water to remove excess surfactant [30].

- Lyophilization: Freeze-dry the nanoparticles with cryoprotectant (e.g., 5% trehalose) for long-term storage [30].

Applications in Nutrient Delivery:

- Nanoemulsions: For improved bioavailability of lipophilic bioactive compounds [9].

- Solid Lipid Nanoparticles: For controlled release of nutrients with enhanced stability [30].

- Polymer-Nutrient Conjugates: For targeted delivery to specific absorption sites [26].

Characterization and Evaluation Methodologies

Essential Characterization Techniques

Table 3: Standard Characterization Methods for Synthesized Nanoparticles

| Analysis Type | Technique | Key Parameters Measured | Protocol Notes |

|---|---|---|---|

| Size & Distribution | Dynamic Light Scattering (DLS) [29] | Hydrodynamic diameter, PDI | Dilute sample in appropriate solvent; measure in triplicate |

| Surface Charge | Zeta Potential [29] | Surface charge, colloidal stability | Measure in low conductivity buffer at neutral pH |

| Morphology | TEM, SEM [25] [29] | Shape, core size, aggregation | Requires sample drying and conductive coating for SEM |

| Crystallinity | XRD [29] | Crystal structure, phase composition | Compare peaks with standard reference patterns |

| Formation & Capping | UV-Vis Spectroscopy [29] [27] | Surface Plasmon Resonance, reduction confirmation | Scan range 200-800 nm; specific peaks indicate formation |

| Functional Groups | FTIR [29] | Biomolecular capping, functionalization | Identify plant metabolite involvement in green synthesis |

| Elemental Composition | EDS [29] | Elemental analysis, purity | Coupled with SEM measurement |

Performance Evaluation for Nutrient Delivery Systems

Nutrient Loading and Encapsulation Efficiency:

- Direct Method: Centrifuge nanoparticle suspension at high speed, collect supernatant, and measure free nutrient concentration using HPLC or UV-Vis spectroscopy [30].

- Calculation:

- Encapsulation Efficiency (%) = (Total nutrient - Free nutrient) / Total nutrient × 100

- Loading Capacity (%) = (Weight of loaded nutrient / Weight of nanoparticles) × 100 [30]

In Vitro Release Kinetics:

- Dialyis Method: Place nanoparticle suspension in dialysis bag (appropriate MWCO) immersed in release medium (e.g., simulated gastric/intestinal fluid) [30].

- Sampling: Withdraw aliquots at predetermined time points and replace with fresh medium to maintain sink conditions [30].

- Analysis: Quantify released nutrient using appropriate analytical method. Plot cumulative release versus time to determine release profile [30].

Bioavailability Assessment:

- Caco-2 Cell Model: Utilize human intestinal epithelial cell lines to study nutrient transport across intestinal barrier [9].

- Measurement: Apparent permeability coefficient (Papp) calculated from transport rate across cell monolayer [9].

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 4: Key Reagents and Materials for Nanoparticle Synthesis and Characterization

| Reagent/Material | Function/Application | Examples/Specifications |

|---|---|---|

| Metal Salt Precursors | Source of metal ions for nanoparticle formation | Silver nitrate (AgNO₃), Zinc acetate, Gold(III) chloride, Iron chloride [29] [27] |

| Biodegradable Polymers | Matrix for polymeric nanoparticles and nanoencapsulation | PLGA, Chitosan, Alginate, Polycaprolactone (PCL) [26] [30] |

| Plant Extracts | Green reducing and stabilizing agents | Ocimum sanctum, Azadirachta indica, Curcuma longa extracts [27] |

| Surfactants/Emulsifiers | Stabilization of nanoemulsions and surface modification | Polysorbates, Phospholipids, Polyvinyl alcohol (PVA) [30] |

| Lipids | Formation of solid lipid nanoparticles and nanoliposomes | Stearic acid, Beeswax, Triglycerides, Phospholipids [30] |

| Characterization Standards | Reference materials for instrument calibration | Latex beads for DLS, Zeta potential transfer standard [29] |

| Cell Culture Models | In vitro bioavailability and toxicity assessment | Caco-2 intestinal cells, HT-29 mucus-producing cells [9] |

Decision Framework and Future Perspectives

The selection of an appropriate synthesis methodology requires careful consideration of the intended application, with green synthesis emerging as particularly advantageous for nutrient delivery systems where biocompatibility and low toxicity are paramount [24] [29]. Chemical methods offer superior control over particle characteristics but require extensive purification to remove toxic residues [27]. Physical methods, while producing high-purity nanoparticles, face challenges in scalability and cost-effectiveness for widespread nutrient delivery applications [27].

Future research should focus on standardizing green synthesis protocols to improve reproducibility while exploring hybrid approaches that combine the precision of chemical methods with the biocompatibility of green synthesis [25] [28]. The development of nutrient-specific nanocarriers with targeted release profiles and enhanced bioavailability represents the next frontier in nanotechnology-enabled nutrient delivery systems [26] [9].

Synthesis Method Decision Pathway

Nanoparticle Characterization Workflow

The efficacy of bioactive compounds, whether therapeutic drugs or essential nutrients, is often hampered by inherent physicochemical limitations and biological barriers. Formulation strategies such as nanoencapsulation, surface functionalization, and ligand targeting are fundamental to advancing nanotechnology for enhanced nutrient delivery systems. These approaches collectively address critical challenges including poor solubility, low bioavailability, instability during processing and storage, and non-specific distribution. By enabling precise control over the behavior of delivery systems within the body, these strategies facilitate the development of targeted, efficient, and safe nanocarriers, pushing the frontiers of personalized nutrition and medicine [31].

Nanoencapsulation Approaches

Nanoencapsulation involves entrapping bioactive compounds within nanoscale carriers to protect them from degradation and enhance their delivery. The choice of material and method dictates the release profile, stability, and ultimate bioavailability of the encapsulated nutrient.

Table 1: Overview of Common Nanoencapsulation Systems

| Nanocarrier Type | Core Materials | Key Advantages | Encapsulation Efficiency (Example) |

|---|---|---|---|

| Polymeric Nanoparticles | PLGA, Chitosan, Alginate, Zein [32] [31] | Biocompatibility, controlled release, high stability | ~92-95% for curcumin in protein nanogels [31] |

| Lipid-Based Carriers | Phospholipids, triglycerides, surfactants [31] | High bioavailability for lipophilic compounds, ease of scale-up | Enhances solubilization and intestinal transport [33] [9] |

| Nanoemulsions | Oil, Water, Emulsifiers [9] [31] | Ease of preparation, transparency, improved solubility | Effective for both hydrophilic and lipophilic compounds [9] |

| Silica Nanospheres | Tetraethyl orthosilicate (TEOS) [34] | High surface area, tunable porosity, rigid structure | Thyme EO loading of 4.18 mg/g in HNSs [34] |

| Hybrid Systems | Chitosan-PLGA, Alginate-PEG [32] | Merges advantages of natural and synthetic polymers | Improved oxidative resistance and environmental resilience [32] |

Principle: This protocol describes the formation of silica hollow nanospheres using a sol-gel process, which involves the hydrolysis and condensation of a silica precursor to create a porous inorganic matrix around essential oil droplets.

Materials:

- Cetyl trimethyl ammonium bromide (CTAB): Surfactant, acts as a structure-directing agent.

- Tetraethyl orthosilicate (TEOS): Silica precursor.

- Ammonia solution (25%): Catalyst for the hydrolysis and condensation reactions.

- Essential Oil (e.g., Thyme or Sage): Core active material to be encapsulated.

- Double-distilled water: Reaction medium.

Procedure:

- Prepare a solution by dissolving 0.082 g of CTAB in 100.00 mL of double-distilled water. Sonicate the mixture for 5 minutes to ensure complete dissolution.

- Under constant stirring, add 0.50 mL of the chosen essential oil to the CTAB solution.

- Introduce 1.00 mL of 25% ammonia solution to create an alkaline medium, which catalyzes the subsequent sol-gel reaction.

- Slowly add 1.00 mL of TEOS dropwise to the reaction mixture while maintaining stirring.

- Subject the entire reaction mixture to sonication for 2 hours to facilitate the formation of uniform nanocapsules.

- Recover the synthesized nanocapsules by centrifugation at 13,000 rpm.

- Wash the pellet thoroughly with distilled water to remove any unreacted reagents or surfactants.

- Freeze-dry the purified nanocapsules for storage and further characterization.

Characterization: The resulting HNSs can be characterized using Field Emission Scanning Electron Microscopy (FE-SEM) for morphology, Dynamic Light Scattering (DLS) for size distribution, and Fourier Transform Infrared Spectroscopy (FT-IR) to confirm encapsulation [34].

Diagram 1: Sol-gel synthesis workflow for silica HNSs.

Surface Functionalization Strategies

Surface functionalization modifies the outer surface of nanocarriers to control their interactions with biological environments, aiming to improve colloidal stability, reduce non-specific binding, and enhance targeting.

Electrostatic Functionalization

Electrostatic adsorption is a crucial non-covalent interaction for loading biomolecules onto nanoparticles. The adsorption is governed by environmental factors such as pH, ionic strength, and temperature, which influence the surface charge of both the nanoparticle and the biomolecule [35]. Functionalization strategies to enhance electrostatic binding include:

- Direct Chemical Functionalization: Covalent modification with small charged molecules (e.g., amine (-NH₂) using (3-aminopropyl)triethoxysilane/APTES for a positive charge, or carboxyl (-COOH) for a negative charge) [35].

- Polymer Wrapping: Coating with charged polymers like polyethyleneimine (PEI, cationic) or poly(acrylic acid) (PAA, anionic) to alter surface potential and provide multivalent interaction sites [35].

- Irradiation-Based Techniques: Emerging methods that directly modulate surface charge without chemical reagents, though these are still underexplored [35].

Principle: This protocol outlines the wrapping of nanoparticles with the cationic polymer polyethyleneimine (PEI) to create a positively charged surface, which promotes the strong adsorption of negatively charged biomolecules like DNA or RNA through electrostatic interactions.

Materials:

- Polyethyleneimine (PEI): Cationic polymer, provides a high density of positive charges.

- Pre-formed Nanoparticles (e.g., PLGA, Silica): Core carrier system.

- Buffer Solution (e.g., MES or HEPES): To control pH during the coating process.

Procedure:

- Prepare a solution of PEI in a suitable buffer at a concentration determined empirically (e.g., 0.1-1 mg/mL).

- Disperse the pre-formed nanoparticles in the PEI solution under gentle vortexing or stirring. The typical mass ratio of PEI to nanoparticles should be optimized, often starting at 1:5.

- Allow the reaction to proceed for a predetermined incubation period (e.g., 30-60 minutes) at room temperature to facilitate the adsorption of the polymer onto the nanoparticle surface.

- Purify the PEI-coated nanoparticles from the free, unbound polymer by centrifugation or dialysis.

- Re-suspend the final coated nanoparticles in a storage buffer (e.g., deionized water or PBS) and store at 4°C until use.

Characterization: Successful coating can be confirmed by a shift in zeta potential from negative or neutral to highly positive. Gel retardation assays can confirm the adsorption of nucleic acids [35].

Table 2: Surface Functionalization Methods and Their Outcomes

| Functionalization Method | Key Reagents | Primary Interaction | Resulting Function |

|---|---|---|---|

| Silanization (APTES) | (3-aminopropyl) triethoxysilane [35] | Covalent | Introduces amine groups for positive surface charge |

| Polymer Wrapping (PEI) | Polyethyleneimine [35] | Electrostatic / Hydrophobic | Renders surface cationic for DNA/RNA binding; enhances stability |

| Polymer Wrapping (Chitosan) | Chitosan [35] [31] | Electrostatic | Biocompatible cationic surface; mucoadhesive properties |

| Click Chemistry | Azide, Alkyne derivatives [35] | Covalent (Bioorthogonal) | Site-specific, efficient ligand attachment for targeting |

| Hybrid Coating | Chitosan, PEG, PLGA [32] | Combined | Merges biocompatibility with "stealth" properties and controlled release |

Ligand Targeting Methodologies

Ligand targeting involves conjugating specific molecules (ligands) to the surface of nanocarriers to enable active targeting and preferential accumulation at the desired site of action, such as tumor cells or inflamed tissues.

Ligand Types and Applications

- Antibodies and Antibody Fragments: Offer high specificity and affinity for tumor-associated antigens (e.g., in antibody-drug conjugates/ADCs for glioma therapy) [36] [37].

- Peptides: Short sequences (e.g., iRGD, Angiopep-2) can target specific receptors overexpressed on target cells or facilitate transport across biological barriers like the blood-brain barrier (BBB) [37].

- Aptamers: Single-stranded DNA or RNA oligonucleotides that bind to molecular targets with high specificity; used in targeted therapies for blood cancers [36].

- Proteins and Vitamins: Natural ligands like transferrin (targeting transferrin receptors) or folic acid (targeting folate receptors) exploit receptor-mediated endocytosis for cellular uptake [37].

Principle: This common bioconjugation protocol uses EDC and NHS to form an amide bond between a carboxyl group on the nanoparticle surface and a primary amine group on the targeting ligand (e.g., a peptide).

Materials:

- 1-Ethyl-3-(3-dimethylaminopropyl)carbodiimide (EDC): Carboxyl-activating agent.

- N-Hydroxysuccinimide (NHS or Sulfo-NHS): Stabilizes the amine-reactive intermediate, increasing conjugation efficiency.

- Targeting Ligand (e.g., Peptide, Antibody): Must contain a primary amine (-NH₂) group.

- Functionalized Nanoparticles: Nanoparticles with surface carboxyl (-COOH) groups.

Procedure:

- Activation Step: Disperse carboxylated nanoparticles in a buffer (e.g., MES, pH 5.5). Add a fresh solution of EDC and NHS (molar excess to COOH groups, e.g., 10:5:1 EDC:NHS:COOH) and incubate for 15-30 minutes with gentle mixing. This step activates the carboxyl groups, forming an NHS ester.

- Purification: Remove excess EDC/NHS by centrifugation, dialysis, or gel filtration. This step is critical to prevent unwanted side reactions.

- Conjugation Step: Re-suspend the activated nanoparticles in a compatible buffer (e.g., PBS, pH 7.4). Add the targeting ligand containing the primary amine group and allow the reaction to proceed for 2-4 hours at room temperature or overnight at 4°C.

- Quenching and Purification: Quench the reaction by adding a small volume of quenching agent (e.g., glycine or ethanolamine) to block any remaining active esters. Purify the conjugated nanoparticles via extensive dialysis or centrifugation to remove unreacted ligands.

- The final product can be stored in an appropriate buffer at 4°C.

Characterization: Conjugation success can be verified using techniques such as X-ray Photoelectron Spectroscopy (XPS) to detect new elemental signatures, fluorescence labeling, or by demonstrating enhanced cellular uptake in target cells versus non-target cells [35].

Diagram 2: Ligand conjugation workflow using EDC/NHS chemistry.

The Scientist's Toolkit: Essential Research Reagents

Table 3: Key Reagents for Nanocarrier Formulation and Functionalization

| Reagent / Material | Function / Role in Formulation | Example Applications |

|---|---|---|

| TEOS (Tetraethyl orthosilicate) | Precursor for synthesizing silica-based nanocarriers via sol-gel processes [34]. | Synthesis of silica hollow nanospheres (HNSs) [34]. |

| PLGA (Poly(lactic-co-glycolic acid)) | Biodegradable, synthetic polymer for forming nanoparticles with controlled release profiles [32]. | Polymeric NPs for drug/nutrient delivery [32] [31]. |

| Chitosan | Natural, biocompatible cationic polymer for encapsulation and functionalization [35] [32] [31]. | Polymer coatings, nanogels, mucoadhesive delivery systems [35] [31]. |

| PEI (Polyethyleneimine) | Cationic polymer for surface coating; enhances adsorption of anionic biomolecules [35]. | Gene delivery (DNA/RNA binding), creating positive surface charge [35]. |

| EDC / NHS Crosslinkers | Catalyze the formation of amide bonds between carboxyl and amine groups for ligand conjugation [35]. | Covalent attachment of antibodies, peptides, and other targeting ligands [35] [37]. |

| CTAB (Cetyl trimethyl ammonium bromide) | Surfactant and structure-directing agent in nanoparticle synthesis [34]. | Controlling size and morphology in silica nanosphere synthesis [34]. |

| PEG (Polyethylene glycol) | Polymer used for "PEGylation" to impart stealth properties, reducing opsonization and extending circulation time [37] [32]. | Surface functionalization to improve pharmacokinetics and stability [37] [32]. |

Nanotechnology has revolutionized the concept of targeted delivery across multiple fields, creating a unified paradigm for enhancing the efficacy and precision of active agents. This article details the application notes and experimental protocols for using nanotechnology in oncology, cardiovascular disease, and agriculture. The core principle across these disciplines involves encapsulating active compounds—whether chemotherapeutic drugs, therapeutic phytochemicals, or plant nutrients—into nanoscale carriers to improve their stability, bioavailability, and targeted delivery. The following sections provide a detailed framework for researchers developing these advanced delivery systems.

Nanotechnology in Oncology

Application Notes

Nanoparticles (NPs) offer transformative advantages in oncology by enhancing drug solubility, prolonging circulation time, and enabling targeted delivery to tumor tissue. Their efficacy stems from the Enhanced Permeability and Retention (EPR) effect, a passive targeting mechanism where nanocarriers (typically 50-200 nm) extravasate through the leaky vasculature of tumors and are retained due to poor lymphatic drainage [38]. Second and third-generation nanoparticles incorporate active targeting and stimulus-responsive release for greater precision.

Table 1: Common Nanocarriers in Oncology and Their Key Characteristics

| Nanocarrier Type | Core Composition | Key Advantages | Primary Applications in Oncology | Noteworthy Formulations |

|---|---|---|---|---|

| Liposomes | Lipid bilayers (natural/synthetic) [39]. | Biocompatibility, co-delivery of hydrophilic/hydrophobic drugs, reduced toxicity [39]. | Targeted drug delivery to resistant cancer cells; reversing drug resistance [39]. | Doxil (PEGylated liposomal doxorubicin) [38], Rg3-PTX-LPs [39]. |

| Polymeric Nanoparticles | Biodegradable polymers (e.g., PLGA, chitosan) [39]. | Controlled release, high stability, protection of payload from degradation [38]. | Crossing biological barriers (e.g., blood-brain barrier), targeted therapy [6]. | Investigational formulations for resveratrol delivery [39]. |

| Dendrimers | Branched macromolecules with core-shell structure [39]. | High drug-loading capacity, functionalizable surface, can overcome multidrug resistance (MDR) [39]. | Co-delivery of drugs and siRNA, downregulating MDR genes like P-glycoprotein [39]. | PAMAM dendrimers [39]. |

| Carbon Nanotubes | Carbon allotropes [39]. | Unique mechanical/optical properties, efficient cell membrane penetration [39]. | Reversing drug resistance pathways (e.g., EMT in glioblastoma) [39]. | Magnetically controlled CNTs (mCNTs) for precise delivery [39]. |

Experimental Protocol: Formulation of Ligand-Targeted Liposomes

This protocol outlines the synthesis of antibody-conjugated liposomes for active tumor targeting.

Research Reagent Solutions

| Reagent/Material | Function | Example/Note |

|---|---|---|

| Phospholipids | Form the primary lipid bilayer structure. | Dipalmitoylphosphatidylcholine (DPPC), hydrogenated soy phosphatidylcholine (HSPC). |

| Cholesterol | Modulates membrane fluidity and stability. | Typically used at 30-45 mol % relative to phospholipids. |

| Polyethylene Glycol (PEG)-Lipid | Confers "stealth" properties to evade immune clearance [38]. | DSPE-PEG2000. Added at 1-5 mol %. |